Abstract

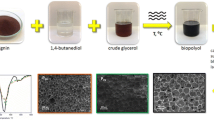

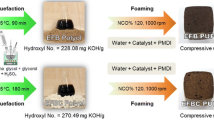

The objective of this investigation was to find a simple method for the production of phenolic-rich products and sugar derivatives via separation of liquefied lignocellulosic materials. After liquefaction, the liquefied products were separated by addition of a sufficient amount of water. It was found that those hydrophobic phenolics could be largely separated from aqueous solutions. Preparation of polyurethane foams using biopolyol and isocyanate was studied. Water was used as an environmentally friendly blowing agent. The factors influencing the cell structure of foams such as catalyst, dosage of blowing agent, and mass ratio of biopolyol to PEG were studied. The microstructure of synthesized foams was characterized by SEM.

Similar content being viewed by others

References

Zhang ZJ, Wang QW, Tripathi P, Pittman CU (2011) Catalytic upgrading of bio-oil using 1-octene and 1-butanol over sulfonic acid resin catalysts. Green Chem 13:940–949

Huber GW, Iborra S, Corma A (2006) Synthesis of transportation fuels from biomass: chemistry, catalysts, and engineering. Chem Rev 106:4044–4098

Zakzeski J, Bruijnincx PCA, Jongerius AL, Weckhuysen BM (2010) The catalytic valorization of lignin for the production of renewable chemicals. Chem Rev 110:3552–3599

Gani A, Naruse I (2007) Effect of cellulose and lignin content on pyrolysis and combustion characteristics for several types of biomass. Renew Energy 32:649–661

Alma MH, Basturk MA, Digrak M (2003) New polyurethane-type rigid foams from liquified wood powders. J Mater Sci Lett 22(17):1225–1228

Chen FG, Lu ZM (2009) Liquefaction of wheat straw and preparation of rigid polyurethane foam from the liquefaction products. J Appl Polym Sci 111(1):508–516

Lee SH, Yoshioka M, Shiraishi N (2000) Liquefaction of corn bran (CB) in the presence of alcohols and preparation of polyurethane foam from its liquefied polyol. J Appl Polym Sci 78(2):319–325

Yan YB, Pang H, Yang XX, Zhang RL, Liao B (2008) Preparation and characterization of water-blown polyurethane foams from liquefied cornstalk polyol. J Appl Polym Sci 110(2):1099–1111

Rivera-Armenta JL, Heinze T, Mendoza-Martinez AM (2004) New polyurethane foams modified with cellulose derivatives. Eur Polym J 40:2803–2812

Ge J, Shi X, Cai M, Wu R, Wang M (2003) A novel biodegradable antimicrobial PU foam from wattle tannin. J Appl Polym Sci 90:2756–2763

Kwon OJ, Yang SR, Kim DH, Park JS (2006) Characterization of polyurethane foam prepared by using starch as polyol. J Appl Polym Sci 103:1544–1553

Junming X, Jianchun J, Chungyun H, Todd FS (2012) Renewable chemical feedstocks from integrated liquefaction processing of lignocellulosic materials using microwave energy. Green Chem 14(10):2821–2830

Li XB, Cao HB, Zhang Y (2008) Properties of water blown rigid polyurethane foams with different functionality. J Wuhan Univ Technol Mater Sci 23(1):125–129

Acknowledgments

The authors would like to thank the “Commonweal Research Foundation of Forestry” (201204801) for financial support during this investigation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Z., Xu, S., Hu, Wp. et al. Fractionation of the Biopolyols from Lignocellulosic Biomass for the Production of Rigid Foams. Bioenerg. Res. 6, 896–902 (2013). https://doi.org/10.1007/s12155-013-9320-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-013-9320-9