Abstract

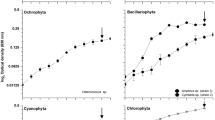

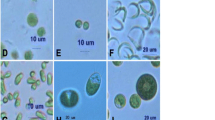

The viability of algae-based biodiesel industry depends on the selection of adequate strains in regard to profitable yields and oil quality. This work aimed to bioprospecting and screening 12 microalgae strains by applying, as selective criteria, the volumetric lipid productivity and the fatty acid profiles, used for estimating the biodiesel fuel properties. Volumetric lipid productivity varied among strains from 22.61 to 204.91 mg l−1 day−1. The highest lipid yields were observed for Chlorella (204.91 mg l−1 day1) and Botryococcus strains (112.43 and 98.00 mg l−1 day−1 for Botryococcus braunii and Botryococcus terribilis, respectively). Cluster and principal components analysis analysis applied to fatty acid methyl esters (FAME) profiles discriminated three different microalgae groups according to their potential for biodiesel production. Kirchneriella lunaris, Ankistrodesmus fusiformis, Chlamydocapsa bacillus, and Ankistrodesmus falcatus showed the highest levels of polyunsaturated FAME, which incurs in the production of biodiesels with the lowest (42.47–50.52) cetane number (CN), the highest (101.33–136.97) iodine values (IV), and the lowest oxidation stability. The higher levels of saturated FAME in the oils of Chlamydomonas sp. and Scenedesmus obliquus indicated them as source of biodiesel with higher oxidation stability, higher CN (63.63–64.94), and lower IV (27.34–35.28). The third group, except for the Trebouxyophyceae strains that appeared in isolation, are composed by microalgae that generate biodiesel of intermediate values for CN, IV, and oxidation stability, related to their levels of saturated and monosaturated lipids. Thus, in this research, FAME profiling suggested that the best approach for generating a microalgae-biodiesel of top quality is by mixing the oils of distinct cell cultures.

Similar content being viewed by others

Abbreviations

- ANP:

-

Brazilian National Agency for Petroleum, Natural Gas and Biofuels

- ASTM:

-

American Society for Testing and Materials

- CFPP:

-

Cold filter plugging point

- CN:

-

Cetane number

- DU:

-

Degree of unsaturation

- FA:

-

Fatty acids

- FAME:

-

Fatty acid methyl esters

- GHG:

-

Greenhouse gases

- IV:

-

Iodine value

- L c :

-

Total lipids content

- LCSF:

-

Long-chain saturated factor

- L p :

-

Volumetric lipid productivity

- MJ:

-

Mega Joule

- MUFA:

-

Monounsaturated fatty acids

- OD:

-

Optical density

- OS:

-

Oxidative stability

- P dwt :

-

Biomass productivity

- PUFA:

-

Polyunsaturated fatty acids

- SV:

-

Saponification value

- TAG:

-

Triglycerides

References

Mata TM, Martins AA, Caetano NS (2010) Microalgae for biodiesel production and other applications: a review. Renew Sust Energ Rev 14:217–232

Altieri MA (2009) The ecological impacts of large-scale agro fuel monocultures’ production systems in the Americas. B Sc Technol Soc 29(3):236–244

Sheehan J, Camobreco V, Duffield J, Graboski M, Shapouri H (1998) Life cycle inventory of biodiesel and petroleum diesel for use in an urban bus. Tech. Rep. NREL/SR-580-24089, U.S. Department of Energy and U.S. Department of Agriculture

Rajagopal D, Zilberman D (2007) Review of the environmental, economic and policy aspects of biofuels. Policy research working paper 4341. The World Bank. 107 pp. Available at http://econ.worldbank.org Accessed September 2011

Meher LC, Vidya SD, Naik SN (2006) Technical aspects of biodiesel production by transesterification—a review. Renew Sust Energy Rev 10:248–268

Wang WG, Lyons DW, Clark NN, Gautam M, Norton PM (2000) Emissions from nine heavy trucks fueled by diesel and biodiesel blend without engine modification. Environ Sci Technol 34:933–939

Tyson KS (2001) Biodiesel Handling and Use Guidelines. Report NREL/TP 580–30004. National Renewable Energy Laboratory, Golden, CO

Gouveia L, Oliveira AC (2009) Microalgae as raw material for biofuels production. J Ind Microbiol Biotech 36:269–274

Singh J, Gu S (2010) Commercialization potential of microalgae for biofuels production. Renew Sust Energ Rev 14:2596–2610

Sander K, Murthy GS (2010) Life cycle analysis of algae biodiesel. Int J Life Cycle Assess 15:704–714

Balat M (2011) Potential alternatives to edible oils for biodiesel production—a review of current work. Energy Convers Manage 52:1479–1492

Chisti Y (2006) Microalgae as sustainable cell factories. Environ Eng Manage J 5(3):261–274

Chisti Y (2007) Biodiesel from microalgae. Biotecnol Adv 25:294–306

Hu G, Sommerfeld M, Jarvis E, Ghirardi M, Posewitz M, Seibert M et al (2008) Microalgal triacylglycerols as feedstocks for biofuel production: perspectives and advances. Plant J 54:621–639

Demirbas A, Demirbas MF (2011) Importance of algae oil as a source of biodiesel. Energy Convers Manage 52:163–170

Wijffels RH (2008) Potential of sponges and microalgae for marine biotechnology. Trends Biotechnol 26:26–31

Xu H, Miao X, Wu Q (2006) High quality biodiesel production from a microalga Chlorella protothecoides by heterotrophic growth in fermenters. J Biotechnol 126:499–507

Campbell MN (2008) Biodiesel: algae as a renewable source for liquid fuel. Guelph Eng J 1:2–7

Mutanda T, Ramesh D, Karthikeyan S, Kumari S, Anandraj A, Bux F (2011) Bioprospecting for hyper-lipid producing microalgal strains for sustainable biofuel production. Bioresour Technol 102:57–70

Demirbas A (2009) Production of biodiesel from algae oils. Energy Source Part A 31:163–168

Demirbas A (2010) Microalgae as feedstock for biodiesel. Energy Edu Sci Technol Part A 26:31–43

Xu L, Derk WF, Brilman W, Withag JAM, Brem G, Kersten S (2011) Assessment of a dry and wet route for the production of biofuels from microalgae: energy balance analysis. Bioresour Technol 102:5113–5122

Wijffels RH, Barbosa MJ (2010) An outlook on microalgal biofuels. Science 329:796–799

Patil PD, Gude VG, Mannarswamy A, Deng S, Cooke P, Munson-McGee S et al (2011) Optimization of direct conversion of wet algae to biodiesel under supercritical methanol conditions. Bioresour Technol 102:118–122

Ras M, Lardon L, Bruno S, Bernet N, Steyer JP (2011) Experimental study on a coupled process of production and anaerobic digestion of Chlorella vulgaris. Bioresour Technol 102:200–206

Huerlimann R, de Nys R, Heimann K (2010) Growth, lipid content, productivity and fatty-acid composition of tropical microalgae for scale-up production. Biotechnol Bioeng 107(2):245–257

Vijayaraghavan K, Hemanathan K (2009) Biodiesel production from freshwater algae. Energ Fuels 23:5448–5453

Schenk P, Thomas-Hall S, Stephens E, Marx U, Mussugnug J, Posten C et al (2008) Second generation biofuels: high efficiency microalgae for biodiesel production. Bioenergy Res 1:20–43

Liu J, Huang J, Sun Z, Zhong Y, Jiang Y, Chen F (2011) Differential lipid and fatty acid profiles of photoautotrophic and heterotrophic Chlorella zofingiensis: assessment of algal oils for biodiesel production. Bioresour Technol 102:106–110

Griffiths MJ, Harrison STL (2009) Lipid productivity as a key characteristic for choosing algal species for biodiesel production. J Appl Phycol 21:493–507

Dayananda C, Sarada R, Ushua RM, Shamala TR, Ravishankar GA (2007) Autotrophic cultivation of Botryococcus braunii for the production of hydrocarbons and exopolysaccharides in various media. Biomass Bioenerg 31:87–93

Richmond A (2004) Handbook of microalgal culture: biotechnology and applied phycology. Blackwell, Oxford, p 566

Rodolfi L, Zitelli GC, Bassi N, Padovani G, Biondi N, Bonini G et al (2008) Microalgae for oil: strain selection, induction of lipid synthesis and outdoor mass cultivation in a low-cost photobioreactor. Biotechnol Bioeng 102:100–112

Levasseur M, Thompson PA, Harrison PJ (1993) Physiological acclimation of marine phytoplankton to different nitrogen sources. J Phycol 29:587–595

Ranga Rao AR, Sarada R, Ravishankar GA (2007) Influence of CO2 on growth and hydrocarbon production in Botryococcus braunii. J Microbiol Biotechnol 17:414–419

Freeman NFT, Lindgren YCN, Nichols AV (1957) Serum lipid analysis by chromatography and infrared spectrophotometry. J Biol Chem 277:449–464

GraphPad Software (1997) Instant guide to choosing and interpreting statistical tests. GraphPad Software Inc., San Diego, CA.

Joseph JD, Ackman RG (1992) Capillary column gas chromatographic method for analysis of encapsulated fish oils and fish oil ethyl esters: collaborative study. J AOAC Intern 75:488–506

Knothe GH (2005) Dependence of biodiesel fuel properties on the structure of fatty acid alkyl esters. Fuel Process Technol 86:1059–1070

Knothe GH (2007) Some aspects of biodiesel oxidative stability. Fuel Process Technol 88:669–677

Ramos MJ, Fernández CM, Casas A, Rodriguez L, Pérez A (2009) Influence of fatty acids composition of raw materials on biodiesel properties. Bioresour Technol 100:261–268

RANP (2008) Resolution from Brazilian National Agency for Petroleum, Natural Gas and Biofuels (2008) Resolução ANP nº 7, de 19.3.2008- DOU 20.3.2008. Available at http://www.anp.gov.br Access: September 2011.

Krisnangkura KA (1986) A simple method for estimation of cetane index of vegetable oil methyl esters. J Am Oil Chem Soc 63:552–553

Francisco EC, Neves DB, Jacob-Lopes E, Franco TT (2010) Microalgae as feedstock for biodiesel production: carbon dioxide sequestration, lipid production and biofuel quality. J Chem Technol Biotechnol 85:395–403

Oksanen J, Blanchet GF, Kindt R, Legendre P, Minchin PR, O’Hara RB et al (2011). VEGAN: Community ecology package. R package version 2.1-3/r1935. Available at http://R-Forge.R-project.org/projects/vegan/

ter Braak CJF (1988) CANOCO—an extension of DECORANA to analyze species–environment relationships. Vegetation 75:159–160

ter Braak CJF, Smilauer P (2002) CANOCO reference manual and CanoDraw for Windows user’s guide: Software for Canonical Community Ordination (version 4.5). Microcomputer Power, Ithaca

Banerjee A, Sharma R, Chisti Y, Banerjee UC (2002) Botryococcus braunii: a renewable source of hydrocarbons and other chemicals. Crit Rev Biotechnol 22(3):245–279

Metzger P, Largeau C (2005) Botryococcus braunii a rich source for hydrocarbons and related ether lipids. App Microbiol Biot 6:486–496

Liang Y, Sarkany N, Cui Y (2009) Biomass and lipid productivities of Chlorella vulgaris under autotrophic, heterotrophic and mixotrphic growth conditions. Biotechnol Lett 3:1043–1049

De-Bashan LE, Antoun H, Bashan Y (2005) Cultivation factors and population size control uptake of nitrogen by the microalgae Chlorella vulgaris, when interacting with the microalgae growth-promoting bacterium Azospirillum brasiliensis. FEMS Microbiol Ecol 54:197–203

Chinnasamy S, Ramakrishnan B, Bhatnagar A, Das KC (2009) Biomass production potential of a wastewater alga Chlorella vulgaris ARC 1 under elevated levels of CO2 and temperature. Int J Mol Sci 10:518–532

Ge Y, Liu J, Tian G (2011) Growth characteristics of Botryococcus braunii 765 under high CO2 Concentration in photobioreactor. Bioresour Technol 102:130–134

Zhila NO, Kalacheva GS, Volova TG (2001) Structure of hydrocarbons synthesized by the alga Botryococcus isolated from Lake Shira. Doklady Biolog Sci 378:265–269

Greenwell HC, Laurens LML, Shields RJ, Lovitt RW, Flynn KJ (2010) Placing microalgae on the biofuels priority list: a review of the technological challenges. J R Soc Interface 7:703–726

Vanitha A, Narayan K, Murphy NC, Ravishankar GA (2007) Comparative study of lipid composition of two halotolerant alga Dunaliella bardawil and Dunaliella salina. Int J Food Sci Nutr 58:373–382

Canakci M, Sanli H (2008) Biodiesel production from various feedstocks and their effects on the fuel properties. J Ind Microbiol Biotechnol 35:431–441

Srivastava A, Prasad R (2000) Triglycerides-based diesel fuels. Ren Sust Energ Rev 4:111–133

Pischinger GM, Falcon AM, Siekmann RW, Fernandes FR (1982) Methylesters of plant oils as diesels fuels, either straight or in blends. Vegetable oil fuels, ASAE publication 4–8. Amer Soc Agric Engrs, St. Joseph, MI

Schwab AW, Bagby MO, Freedman B (1987) Preparation and properties of diesel fuels from vegetable oils. Fuel 66:1372–1378

Mittelbach M, Remschmidt C (2004) In: Mittelbach M (ed) Biodiesel: the comprehensive handbook. Karl-Franzens University, Graz

Wu M, Wu G, Han L, Wang J (2005) Low temperature fluidity of biodiesel fuel prepared from edible vegetable oil. Pet Process Petrochem 35:57–60

Harrington KJ (1986) Chemical and physical properties of vegetable oil esters and their effect on diesel fuel performance. Biomass 9:1–17

Acknowledgments

This work benefited from the support from the National Council for the Scientific and Technological Development (CNPQ)/Science and Technology Ministry, Brazil (processes 574712/2008-9 and 551134/2010-0).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nascimento, I.A., Marques, S.S.I., Cabanelas, I.T.D. et al. Screening Microalgae Strains for Biodiesel Production: Lipid Productivity and Estimation of Fuel Quality Based on Fatty Acids Profiles as Selective Criteria. Bioenerg. Res. 6, 1–13 (2013). https://doi.org/10.1007/s12155-012-9222-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-012-9222-2