Abstract

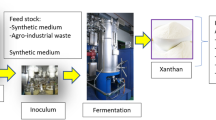

Xanthan is a important biopolymer for commercial purpose and it is produced in two stages by Xanthomonas campestris. In the first one, the bacterium is cultivated in the complex medium enriched in nitrogen and the biomass produced is used as inoculum for the next stage in which the gum is produced in another medium. In this work a new medium for the first stage is proposed in place of currently used YM medium. Different formulated growth media were studied and the correspondent biomass produced was analysed as inoculum for the second stage. The inoculum and gum were produced by batch process in shaker at 27°C in pH 6.0 and at 30°C in pH 7.0, respectively. The gum was precipitated with ethanol (3:1 v/v). The dryed biomass and xathan gum produced were determined by drying in oven at 105 and 40°C, respectively. The viscosity of the fermentation broth and 1% gum solution in water were determined in Brookfield viscometer. The formulated medium presented the increase in gum production (30%), broth (136%) and 1% gum solution viscosity (60%) compared to YM, besides the inferior cost. The results showed the importance of the quality of the inoculum from the first stage of the culture which influenced on the gum viscosity in the second stage.

Similar content being viewed by others

References

Rosalam S, England R (2006) Review of xanthan gum production from unmodified starches by Xanthomonas campestris sp. Enzym Microbial Technol 39:197–207

Faria S, Vieira PA, Resende MM, França FP, Cardoso VL (2009) A Comparison between shaker and bioreactor performance based on the kinetic parameters of xanthan gum production. Appl Biochem Biotechnol 156:475–488

Papagianni M, Psomas SK, Batsilas L, Paras SV, Kyriakidis DA, Liakopouloukyriakides M (2001) Xanthan production by Xanthomonas campestris in batch cultures. Process Biochem 37:73–80

Casas JA, Santos VE, Garcia-Ochoa F (2000) Xanthan gum production under several operational conditions: molecular structure and Rheological properties. Enzym Microb Technol 26:282–291

Druzian JI, Pagliarini AP (2007) Xanthan gum production by fermentation from residue of apple juice. Ciência e Tecnologia de Alimentos 27:26–31

Garcia-Ochoa F, Santos VE, Fritsch AP (1992) Nutritional study of Xanthomonas campestris in xanthan gum production by factorial design of experiments. Enzym Microb Technol 14:991–996

Kalogiannis S, Iakovidou G, Liakopoulou-Kyriakides M (2003) Optimization of xanthan gum production by Xanthomonas campestris grown in molasses. Process Biochem 39:249–256

Letisse F, Chevallereau P, Simon J, Lindley N (2002) The influence of metabolic network structures and energy requirements on xanthan gum yields. J Biotechnol 99:307–317

Souza DM (2004) Fermentative production of extracellular polysaccharides by bacteria. Semin Agric Sci 25:331–340

Garcia-Ochoa F, Santos VE, Casas JA, Gómez E (2000) Xanthan gum: production, recovery, and properties. Biotechnol Adv 18:549–579

Souw P, Demain AL (1979) Nutritional studies on xanthan production by Xanthomonas campestris NRRL-B-1459. Appl Environ Microbiol 37:1186–1192

Cadmus MC, Knutson CA, Lagoda A (1978) Synthetic media for production of quality xanthan gum in 20 liter fermentors. Biotech Bioeng 20:1003–1014

Nitschke M, Rodrigues V, Schinatto LF (2001) Formulação de meios de cultivo à base de soro de leite para produção de goma xantana por X. campestris C7L. Ciência e Tecnologia de Alimentos 21:82–85

De Vuyst L, Loo J, Vandame EJ (1987) Two steps fermentation process for improved xanthan production by X. campestris NRRL-B-1459. J Chem Technol Biotechnol 39:263–273

Funahashi H, Machara M, Tagushi H, Yoshida T (1987) Effect of glucose concentration on xanthan gum production by Xanthomonas campestris. J Chem Eng Jpn 65:603–606

Lo YM, Yang ST, Min DB (1997) Effects of yeast extract and glucose on xanthan production and cell with in batch culture of Xanthomonas campestris. Appl Microbiol Biotechnol 47:689–694

Souw P, Demain AL (1980) Role of citrate in xanthan production by Xanthomonas campestris. J Ferment Technol 58:411–416

Esgalhado ME, Caldeira AT, Roseiro JC (2002) Sublethal acid stress and uncoupling effects on cell growth and product formation in Xanthomonas campestris cultures. Biochem Eng J 12:181–192

Galindo E, Salcedo G, Flores C, Ramírez E (1993) Improved shake-flask test for the screening of xanthan producing microorganisms. World J Microb Biotechnol 9:122–124

Kurbanoglu EB, Kurbanoglu NI (2007) Ram horn hydrolysate as enhacer of xanthan production in batch culture of Xanthomonas campestris EBK-4 isolate. Process Biochem 42:1146–1149

Available at: http://www.bacteria.us.com/Difco-Yeast-Nitrogen-Base-Bacto-YPD-Mold-Agar-YPD-Difco.htm. Accessed 09 February 2011

Available at: http://www.kaycircle.com/What-Is-The-Average-Cost-Of-Xanthan-Gum-Per-Pound-Ton-Average-Xanthan-Gum-Price. Accessed 09 Feb 2011

Jeanes A et al (1976) Polysaccharide xanthan of Xanthomonas campestris NRRL B-1459: culture of maintenance procedures polysaccharide production and purification and analysis. ARS-NC-51. Agricultural Research Service. U.S. Department of Agriculture, Peoria

Nelson MA (1944) Photometric adaptation of the Somogy method for the determination of glucose. J Biol Chem 153:379–380

Pirt JS (1975) Principles of microbe and cell cultivation. BlackWell Scientific Publications Ltd, Oxford

Flores Deckwer (1999) Effect of the nitrogen source on pyruvate content and rheological properties of xanthan. Biotechnol Prog 15:446–452

Gandhi HP, Ray RM, Patel RM (1997) Exopolymer production by Bacillus species. Carbohydr Polym 34:323–327

Diaz PS (2000) Determination of the viscosity of polymers obtained with different concentrations of sucrose in the medium of production, vol 1. In:Proceedings of the International Congress of Nutrition, Food and Technology, p. 330–338

Oliveira LHS, Dias FG, Duarte ICS, Oliva-Neto P, Cruz R, Moreira AS, Vendruscolo CT (2000) Isolamento e caracterização de bactérias produtoras de goma xantana. Plural 1:115–120

Shatwell KP, Sutherland IW, Ross-Murphy SB (1990) Influence of acetyl and pyruvate substituents on the solution properties of xanthan polysaccharide. Int J Biol Macromol 12:71–78

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Carignatto, C.R.R., Oliveira, K.S.M., de Lima, V.M.G. et al. New Culture Medium to Xanthan Production by Xanthomonas campestris pv. campestris . Indian J Microbiol 51, 283–288 (2011). https://doi.org/10.1007/s12088-011-0171-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12088-011-0171-9