Abstract

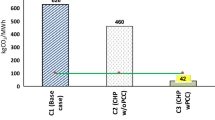

The emphasis of this paper is to show the existence of some non-energy benefits that can be taken into account in an energy efficiency investment aimed to reduce energy consumption and increase production and product quality in an oil and gas processing center (OGPC) in México. The function of OGPC is to separate crude oil, gas, and saltwater coming from marine and terrestrial oil fields. Traditionally, application of process energy integration techniques has been aimed to reduce energy consumption associated with heating and cooling services. In this paper, the process energy integration (standard pinch analysis) of an OGPC shows the possibility of reducing natural gas and electricity consumption by 75 % and 98 %, respectively. However, the novel aspect of this work is the identifications and use of some waste heat streams available in processes to reduce energy consumption, and more importantly couple them with some non-energy-related benefits to produce massive economical savings. For example, by allowing an improvement in the quality of heavy crude oil for exportation (reduction in salt content), an increased sale price of 0.6 USD/barrel is achieved, rising profit to 156.88 MMUSD/year. Additional economic benefits came from the restauration of the production of 3,711 barrel of naphtha per day (33.86 MMUSD/year), by solving security issues related to the use of direct-fire heaters in the condensate stabilization plant.

Similar content being viewed by others

References

California Air Resources Board, Stationary Source Division (2014). Energy efficiency and co-benefits assessment of large industrial sources oil and gas production and mineral processing sectors report.

Campana, F., Bianchi, M., Branchini, L., De Pascale, A., Peretto, A., Baresi, M., Fermi, A., Rossetti, N., & Vescovo, R. (2013). ORC waste heat recovery in European energy intensive industries: energy and GHG savings. Energy Conversion and Management, 76(2013), 244–252.

Colley, D.G.; Young, B.R. (2009). Upstream oil and gas facility energy efficiency tools, Journal of Natural Gas Science and Engineering, v 1, n 3, p 59–67.

Finman, H. and J. Laitner. (2002). Industry, energy efficiency, and productivity improvements, US Environmental Protection Agency (US EPA) White Paper, US EPA, Washington DC.

IEA (International Energy Agency) Report (2014). Capturing the Multiple Benefits of Energy Efficiency, Paris: OECD/IEA.

INECC, Instituto Nacional de Cambio Climatico, México, Report. (2014). Factores de emisiones de diferentes tipos de combustibles fósiles.

IPIECA (International Petroleum Industry Environmental and Conservation Association), Report (2013). Saving energy in the oil and gas industry,

Khatita, M. A., Ahmed, T. S., Ashour, F. H., & Ismail, I. M. (2014). Power generation using waste heat recovery by organic Rankine cycle in oil and gas sector in Egypt: a case study. Energy, 64, 462–472.

Labeyrie, H., Rocher, A. (2010). Reducing flaring and improving energy efficiency: an operator’s view. Society of Petroleum Engineers - SPE International Conference on Health, Safety and Environment in Oil and Gas Exploration and Production, 2, 1025–1035, Rio de Janeiro, Brazil .

Li, K.J., Thijssen, Nort, Mittendorff, Ilse. (2007). Enhancement of oil and gas production using integrated network analysis. International Petroleum Technology Conference, v 3, p 1460–1463, Dubai, United Arab Emirates.

Lilly, P. and Pearson, D.. (1999). Determining the full value of industrial efficiency programs. Proceedings from the 1999 ACEEE Summer Study on Energy Efficiency in Industry, Saratoga Springs,

Linnhoff, B., Townsend, D.W., Boland, D., Hewitt, G.F., Thomas, B.E.A., Guy, A.R., et al. (1982). User guide on process integration for efficient use of energy, London; Institution of Chemical Engineers, pp. 25–31.

Lung, R.B., McKane, A., Leach, R., Marsh, D. (2005). Ancillary savings and production benefits in the evaluation of industrial energy efficiency measures. In: Proceedings ACEEE Summer Study on Energy Efficiency in Industry, pp. 104e114.

Michele, M., Giuseppe, G., Gianluca, V., Romano, M. C., Stefano, B., Stefano, M., Paolo, S., Antonio, G., Emanuele, N., & Ennio, M. (2011). Revamping, energy efficiency, and exergy analysis of an existing upstream gas treatment facility. Journal of Energy Resources Technology, 33(1), 012001.

OGPC, Oil and Gas Processing Center, Pemex Exploration and Production, México (2017).

Popli, S., Rodgers, P., Eveloy, V., Al Hashimi, S., Radermacher, R., & Hwang, Y. (2011). Boosting energy efficiency using waste-heat-powered absorption chillers. Publisher: Society of Petroleum Engineers (SPE), United States, SPE Projects, Facilities and Construction, 6(4), 232–238.

Pye, M., & McKane, A. (2000). Making a stronger case for industrial energy efficiency by quantifying non-energy benefits. Resources, Conservation and Recycling, 28(3–4), 171–183.

Rasmussen, J. (2017). The additional benefits of energy efficiency investments-a systematic literature review and a framework for categorization. Energy Efficiency, 10, 1401–1418.

Sahil, P., Peter, R., & Valerie, E. (2012). Trigeneration scheme for energy efficiency enhancement in a natural gas processing plant through turbine exhaust gas waste heat utilization. Applied Energy, (93), 624–636.

Sauter, R., and Volkery, A. (2013). Review of costs and benefits of energy savings. Task 1 Report. IEEP. Brussels: IEEP for the Coalition of Energy Savings.

Therese, N., & Rasmusse, J. (2016). How do firms consider non-energy benefits? Empirical findings on energy-efficiency investments in Swedish industry. Journal of Cleaner Production, 113(1), 472–482.

Valerie, E., Peter, R. (2012). Sources and potential utilization of waste heat at a natural gas processing facility in the Middle East. ASME 11th Biennial Conference on Engineering Systems Design and Analysis v 2, Paper No. ESDA2012–82986, p 599–609; Nantes, France, July 2–4.

Worrell, E. et al. (2003). Productivity benefits of industrial energy efficiency measures, Energy, Vol. 28, No. 11.

Acknowledgments

The authors wish to thank the Pemex Exploración y Producción for the process data supplied.

Funding

Financial support of this project was from the Instituto Nacional de Electricidad y Energías Limpias, Mexico.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Non-energy benefits have been analyzed to improve the financial attractiveness of energy efficiency investments

• Energy analysis can be aimed not only to reduce energy consumption but also to increase product quality and production

• Waste heat recovery potentials are exploited in the context of full thermal integration of an oil and gas processing center.

Rights and permissions

About this article

Cite this article

Arriola-Medellín, A.M., López-Cisneros, L.F., Aragón-Aguilar, A. et al. Energy efficiency to increase production and quality of products in industrial processes: case study oil and gas processing center. Energy Efficiency 12, 1619–1634 (2019). https://doi.org/10.1007/s12053-019-09803-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12053-019-09803-0