Abstract

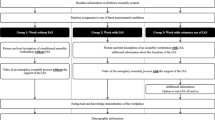

In most manufacturing units, the contribution of human labor remains a vital element that affects overall performance and output. The research explicated in this paper is conducted in a pen recycling unit in the southern part of India which is an initiative by a non-profit organization to reduce plastic waste and highlight the need for recycling. The objectives of the study are two-fold. Firstly, to investigate the influence of cognitive aspects namely information and material presentation on worker performance in an assembly line and secondly to propose an economical worker allocation approach based on the findings of the first study considering the pen recycling unit. An experimental study was conducted with fifteen workers and was given eight different scenarios with the combinations of presenting material and information with six pen varieties for assembly. The performance of workers is identified and appropriate allocations are made to suitable workstations. Further, a subjective measurement using NASA-TLX is also done to determine the mental workload of workers. The results indicate that individual worker performance varies significantly, much more than is assumed. This variation is due to the difference in cognitive capabilities among workers when they are introduced to different product variants and work environments. It is expected that the proposed economical allocation method will be beneficial for similar micro, small and medium enterprises that contribute in achieving sustainability goals.

Similar content being viewed by others

References

Hu S J, Ko J, Weyand L, ElMaraghy H A, Lien T K, Koren Y and Shpitalni M 2011 Assembly system design and operations for product variety. CIRP Annals. 60(2): 715–733

Grosse E H, Glock C H, Jaber M Y and Neumann W P 2015 Incorporating human factors in order picking planning models: framework and research opportunities. Int. J. Production Research. 53(3): 695–717

Burnston D C 2017 Is aesthetic experience evidence for cognitive penetration? New Ideas in Psychology. 47: 145–156

Stokes D 2012 Perceiving and desiring: A new look at the cognitive penetrability of experience. Philosophical studies. 158(3): 477–492

Galy E, Cariou M and Mélan C 2012 What is the relationship between mental workload factors and cognitive load types? Int. J. Psychophysiology. 83(3): 269–275

Brolin A 2016 An investigation of cognitive aspects affecting human performance in manual assembly. Dissertation, Loughborough University

Belletier C, Charkhabi M, de Andrade Silva G P, Ametepe K, Lutz M and Izaute M 2021 Wearable cognitive assistants in a factory setting: a critical review of a promising way of enhancing cognitive performance and well-being. Cognition, Technology & Work. 23(1): 103–116

Kunamaneni S, Jassi S and Hoang D 2019 Promoting reuse behaviour: Challenges and strategies for repeat purchase, low-involvement products. Sustainable Production and Consumption. 20: 253–272

White K, Habib R and Hardisty D J 2019 How to SHIFT consumer behaviors to be more sustainable: A literature review and guiding framework. Journal of Marketing. 83(3): 22–49

Creswell J W and Clark V L P 2017 Designing and conducting mixed methods research. 3rd edn. Sage publications

Hanson R and Brolin A 2013 A comparison of kitting and continuous supply in in-plant materials supply. Int. J. Production Research. 51(4): 979–992

Brolin A, Bäckstrand G, Högberg D and Case K 2011 Use of kitting to ease assemblers' cognitive workload. In: 43rd Annual NES Conference Oulu, Finland. 77–82

Brolin A, Bäckstrand G, Thorvald P, Högberg D and Case K 2012 Kitting as an information source in manual assembly. Advances in Ergonomics in Manufacturing. 10: 346–53

Gualtieri L, Palomba I, Merati F A, Rauch E and Vidoni R 2020 Design of human-centered collaborative assembly workstations for the improvement of operators’ physical ergonomics and production efficiency: A case study. Sustainability. 12(9): 3606

Lim J T and Hoffmann E R 2015 Strategies in performing a manual assembly task. Int. J. Industrial Ergonomics. 50: 121–129

Säfsten K, Winroth M and Löfving M 2014 Usability of a manufacturing strategy framework developed for SMEs. In: Proceedings of the 6th Swedish Production Symposium, Göteborg, Sweden

Peter T 2011 Presenting information in manual assembly. Dissertation, Loughborough University, Loughborough

Bäckstrand G, Thorvald P, De Vin L J, Högberg D and Case K 2008 The impact of information presentation on work environment and product quality: a case study. In: 40th Annual Conference of the Nordic Ergonomics Society Reykjavík, Iceland

Brolin A, Thorvald P and Case K 2017 Experimental study of cognitive aspects affecting human performance in manual assembly. Production & Manufacturing Research. 5(1): 141–163

Mattsson S, Gullander P, Harlin U, Bäckstrand G, Fasth Å and Davidsson A 2012 Testing complexity index–a method for measuring perceived production complexity. Procedia CIRP 3: 394–399

Mattsson S, Fasth Å, Stahre J, Karlsson M, Dencker K, Gullander P and Davidsson A 2013 Validation of the complexity index method at three manufacturing companies. IEEE ISAM. 55–57

Lindblom J and Thorvald P 2014 Towards a framework for reducing cognitive load in manufacturing personnel. Advances in Cognitive Engineering and Neuroergonomics. 11: 233–244

Thorvald P, Lindblom J and Andreasson R 2019 On the development of a method for cognitive load assessment in manufacturing. Robotics and Computer-Integrated Manufacturing 59: 252–266

Bligård L O and Osvalder A L 2017 Evaluating usability problems and use errors in ergonomic products: comparing analytical methods and usability test. International Journal of Human Factors and Ergonomics. 5(1): 1–21

Ghalenoei M, Mortazavi S B, Mazloumi A and Pakpour A H 2021 Impact of workload on cognitive performance of control room operators. Cognition, Technology & Work. 1–13

Battaïa O, Delorme X, Dolgui A, Hagemann J, Horlemann A, Kovalev S and Malyutin S 2015 Workforce minimization for a mixed-model assembly line in the automotive industry. Int. J. Production Economics. 170: 489–500

Hansen K R and Grunow M 2015 Modelling ramp-up curves to reflect learning: improving capacity planning in secondary pharmaceutical production. Int. J. Production Research. 53(18): 5399–5417

Wang Q, Sowden M and Mileham A R 2013 Modelling human performance within an automotive engine assembly line. Int. J. Advanced Manufacturing Technology. 68(1–4): 141–148

Maurizio F, Ferrari E, Mauro G and Pilati F 2019 Human Factor Analyser for work measurement of manual manufacturing and assembly processes. Int. J. Advanced Manufacturing Technology. 103(1–4): 861–877

Sweller J 1988 Cognitive load during problem solving: Effects on learning. Cognitive Science. 12(2): 257–285

Antonenko P, Paas F, Grabner R and Van Gog T 2010 Using electroencephalography to measure cognitive load. Educational Psychology Review. 22(4): 425–438

Kumar N and Kumar J 2019 Selection of Control Panel Design Using Cognitive Load Parameters Based on Physiological Data: An Experimental Study. The Design Journal. 22(5): 607–626

Cain B 2007 A review of the mental workload literature. Defence Research and Development, NATO RTO Report Toronto, Canada

Haga S, Shinoda H and Kokubun M 2002 Effects of task difficulty and time-on-task on mental workload. Japanese Psychological Research. 44(3): 134–143

Kalakoski V, Selinheimo S, Valtonen T, Turunen J, Käpykangas S, Ylisassi H, Toivio P, Järnefelt H, Hannonen H and Paajanen T 2020 Effects of a cognitive ergonomics workplace intervention (CogErg) on cognitive strain and well-being: a cluster-randomized controlled trial. A study protocol. BMC Psychology 8(1): 1

Dalle Mura M and Dini G 2019 Optimizing ergonomics in assembly lines: A multi objective genetic algorithm. CIRP Journal of Manufacturing Science and Technology 27: 31–45

Karas A and Ozcelik F 2021 Assembly line worker assignment and rebalancing problem: A mathematical model and an artificial bee colony algorithm. Computers & Industrial Engineering 156: 107195

Eysenck M W, Derakshan N, Santos R and Calvo M G 2007 Anxiety and cognitive performance: attentional control theory. Emotion 7(2): 336

Vanneste P, Raes A, Morton J, Bombeke K, Van Acker B B, Larmuseau C, Depaepe F and Van den Noortgate W 2021 Towards measuring cognitive load through multimodal physiological data. Cognition, Technology & Work 23(3): 567–585

Hashemi-Petroodi S E, Dolgui A, Kovalev S, Kovalyov M Y and Thevenin S 2020 Workforce reconfiguration strategies in manufacturing systems: a state of the art. Int. J. Production Research. 1–24

Giridhar M P and Panicker V V 2020 Experimental analysis of cognitive issues impacting manual assembly task. In 2020 ICSCAN, IEEE. 1–6

Leppink J, Paas F, Van der Vleuten C P, Van Gog T and Van Merriënboer J J 2013 Development of an instrument for measuring different types of cognitive load. Behavior Research Methods. 45(4): 1058–1072

Giridhar M P and Panicker V V 2021 Assessing Cognitive Behavior of Subjects Using Learning Effect and NASA-TLX in a Manual Pen Assembly. In: Advances in Materials and Mechanical Engineering, Springer Singapore. 401–410

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

GIRIDHAR, M.P., PANICKER, V.V. Does cognitive aspects of information and material presentation matter in worker allocation in an assembly line? A case study of a recycling unit in India. Sādhanā 48, 23 (2023). https://doi.org/10.1007/s12046-023-02078-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-023-02078-3