Abstract

In the past two decades number of studies have been reported on the use of fused deposition modeling (FDM) for the master pattern printing of dental crowns (DC) followed by metal investment casting (IC) in human dentistry applications. But hitherto little has been reported on 3D printed DC as master patterns for strategic teeth (ST) of veterinary patients (VP) (canine species). This paper outlines the effect of pre and post-processing parameters of FDM for the printing of acrylonitrile butadiene styrene (ABS) master patterns for DC of canine ST. The result of the study suggests that the master pattern for DC prepared at orientation angle (90°), density (high), and post-processing temperature (90°C) are the best settings for dimensional accuracy (Δd) and surface hardness (based upon multi-factor optimization approach) for possible IC applications. The results are also supported by scanning electron microscopy (SEM) analysis to understand the effect of stair-casing on surface roughness (Ra) profiles while printing patterns.

Similar content being viewed by others

References

Horn T J and Harrysson O L 2012 Overview of current additive manufacturing technologies and selected applications. Sci. Prog. 95(3): 255–282

Pham D T and Dimov S S 2003 Rapid prototyping and rapid tooling—the key enablers for rapid manufacturing. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 217(1): 1–23

Campbell I, Diegel O, Kowen J and Wohlers T 2018 Wohlers report 2018: 3D printing and additive manufacturing state of the industry: annual worldwide progress report. Wohlers Associates

Singh S, Ramakrishna S and Singh R 2017 Material issues in additive manufacturing: A review. J. Manuf. Process. 25: 185–200

Azari A and Nikzad S 2009 The evolution of rapid prototyping in dentistry: a review. Rapid Prototyp. J. 15(3): 216–225

Bae E J, Jeong I D, Kim W C and Kim J H 2017 A comparative study of additive and subtractive manufacturing for dental restorations. J. Prosthetic Dent. 118(2): 187–193

Lee S, Hong S J, Paek J, Pae A, Kwon K R and Noh K 2019 Comparing accuracy of denture bases fabricated by injection molding, CAD/CAM milling, and rapid prototyping method. J. Adv. Prosthodont. 11(1): 55

Deradjat D and Minshall T 2017 Implementation of rapid manufacturing for mass customisation. J. Manuf. Technol. Manag. 28(1): 95–121

Keleş Ö, Blevins C W and Bowman K J 2017 Effect of build orientation on the mechanical reliability of 3D printed ABS. Rapid Prototyp. J. 23(2): 320–328

Ahn S H, Lee C S and Jeong W 2004 Development of translucent FDM parts by post-processing. Rapid Prototyp. J. 10(4): 218–224

Ma Q, Rejab M R M, Kumar A P, Fu H, Kumar N M and Tang J 2020 Effect of infill pattern, density and material type of 3D printed cubic structure under quasi-static loading. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci.. https://doi.org/10.1177/0954406220971667

Rezaei R, Karamooz Ravari M R, Badrossamay M and Kadkhodaei M 2017 Mechanical characterization and finite element modeling of polylactic acid BCC-Z cellular lattice structures fabricated by fused deposition modeling. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 231(11): 1995–2004

Kumar S, Singh R, Singh T P and Batish A 2019 Multimaterial printing and characterization for mechanical and surface properties of functionally graded prototype. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 233(19–20): 6741–6753

Nsengimana J, Van der Walt J, Pei E and Miah M 2019 Effect of post-processing on the dimensional accuracy of small plastic additive manufactured parts. Rapid Prototyp. J. 25(1): 1–12

Dave H K, Patadiya N H, Prajapati A R and Rajpurohit S R 2019 Effect of infill pattern and infill density at varying part orientation on tensile properties of fused deposition modeling-printed poly-lactic acid part. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 235(10): 1811–1827

Capik I, Ledecký V and Ševčík A 2000 Tooth fracture evaluation and endodontic treatment in dogs. Acta Veterinaria Brno 69(2): 115–122

Box V H, Sukotjo C, Knoernschild K L, Campbell S D and Afshari F S 2018 Patient-reported and clinical outcomes of implant-supported fixed complete dental prostheses: a comparison of metal-acrylic, milled zirconia, and retrievable crown prostheses. J. Oral Implantol. 44(1): 51–61

Pradhan S R, Singh R and Banwait S S 2020 A-frame work on crown fabrication for veterinary patients using 3D thermoplastic and metal printing. Ref. Mod. Mater. Sci. Mater. Eng.. https://doi.org/10.1016/B978-0-12-820352-1.00063-8

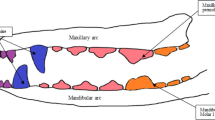

Lemmons M and Beebe D 2019 Oral anatomy and physiology. Wiggs's Veterinary Dentistry: Principles and Practice, pp. 1–24

Ashley M, McCullagh A and Sweet C 2005 Making a good impression:(a “how to” paper on dental alginate). Dent. Update 32(3): 169–170

Al Qahtani M A, Alrefaie M, Altamimi A, Aljowyed I, Al Qahtani M A, AlQahtani A and Habib S R 2019 Evaluation of pre-alginate impression preparation methods in the surface accuracy of dental cast. Saudi Dent. J. 31(4): 451–456

Hayashi K, Sachdeva A U, Saitoh S, Lee S P, Kubota T and Mizoguchi I 2013 Assessment of the accuracy and reliability of new 3-dimensional scanning devices. Am. J. Orthodontics Dentofac. Orthopedics 144(4): 619–625

Bansal M and Dhami S S 2017 3D scanning for reverse engineering-technological advancements, process overview, accuracy inspection, challenges, and remedies. Int. J. Emerg. Technol. Eng. Res. 10(5): 33–40

Coffman C, Visser C, Soukup J and Peak M 2019 Crowns and Prosthodontics. Wiggs's Veterinary Dentistry: Principles and Practice, pp. 387–410

DiBenedetto A T 1987 Prediction of the glass transition temperature of polymers: a model based on the principle of corresponding states. J. Polym. Sci. Part B: Polym. Phys. 25(9): 1949–1969

Yazdi M H and Lee-Sullivan P 2009 Determination of dual-glass transition temperatures of a PC/ABS blend using two TMA modes. J. Therm. Anal. Calorim. 96(1): 7–14

Rahman M, Schott NR and Sadhu L K 2016 Glass transition of ABS in 3D printing. In: COMSOL Conference, Boston, MA

Panda B N, Bahubalendruni R M, Biswal B B and Leite M 2017 A CAD-based approach for measuring volumetric error in layered manufacturing. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 231(13): 2398–2406

Singh R, Singh I and Kumar R 2019 Mechanical and morphological investigations of 3D printed recycled ABS reinforced with bakelite–SiC–Al2O3. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 233(17): 5933–5944

Kumar N and Kumar Jain P 2019 Analysing the influence of raster angle, layer thickness, and infill rate on the compressive behavior of EVA through CNC-assisted fused layer modeling process. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 235(10): 1731–1740

Singh G, Singh R and Singh S 2019 Partial dentures by centrifugal casting assisted by additive manufacturing. Sadhana 44: 143 (1–11)

Pradhan S R, Singh R, Banwait S S, Singh S and Anand A 2021 3D printing assisted dental crowns for veterinary patients. Ref. Mod. Mater. Sci. Mater. Eng.. https://doi.org/10.1016/B978-0-12-820352-1.00153-X (In-Press)

Acknowledgements

The author(s) are thankful to the Department of Science and Technology (GoI) for providing research facilities under the FIST project (File No. SR/FST/COLLEGE/2020/997) and for financial support from DBT (GoI) (File No.102/IFD/SAN/533/2017-18). Also, special thanks to Precision Ceramic Artz, Dental Laboratory, Mohali, Punjab (India), Guru Angad Dev Veterinary and Animal Science University, Ludhiana, Punjab (India), Panjab University, Chandigarh (India), and National Institute of Technical Teachers Training and Research, Chandigarh (India) for lab facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pradhan, S.R., Singh, R., Banwait, S.S. et al. On pre and post-processing parameters of FDM for the development of crowns for strategic teeth of canines. Sādhanā 47, 164 (2022). https://doi.org/10.1007/s12046-022-01941-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-022-01941-z