Abstract

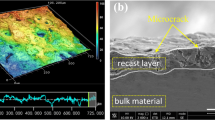

In the present study, finite element thermal modeling of wire electrical discharge machining (WEDM) process for Nitronic-30 has been done. The modeling has been done by considering important aspects such as energy distribution factor, Gaussian heat distribution and latent heat of fusion to predict thermal behavior as well as material removal mechanism in WEDM process. The Temperature distribution on the work piece has been computed using ANSYS software and temperature distribution profiles obtained are used to determine the theoretical MRR. Validation of model MRR with experimental MRR shows very good agreement.

Similar content being viewed by others

References

Karidkar S and Dabade U 2016 Finite Element Modeling and Simulation of Inconel 718 Using WEDM ASME 2016 International Mechanical Engineering Congress and Exposition

Banerjee S, Prasad B and Mishra P 1993 A simple model to estimate the thermal loads on an EDM wire electrode. Journal of Materials Processing Technology. 39: 305–317

Das S and Joshi S 2010 Modeling of spark erosion rate in microwire-EDM. The International Journal of Advanced Manufacturing Technology. 48: 581–596

Dekeyser W, Snoeys R and Jennes M 1988 Expert system for wire cutting EDM, based on pulse classification and thermal modeling. Robotics and Computer-Integrated Manufacturing. 4: 219–224

Van Dijck F and Dutre W 1974 Heat conduction model for the calculation of the volume of molten metal in electric discharges. Journal of Physics D: Applied Physics. 7: 899–910

Kalajahi M, Ahmadi S and Oliaei S 2013 Experimental and finite element analysis of EDM process and investigation of material removal rate by response surface methodology. The International Journal of Advanced Manufacturing Technology. 69: 687–704

Joshi S and Pande S 2010 Thermo-physical modeling of die-sinking EDM process. Journal of Manufacturing Processes. 12: 45–56

Kansal H, Singh S and Kumar P 2008 Numerical simulation of powder mixed electric discharge machining (PMEDM) using finite element method. Mathematical and Computer Modelling. 47: 1217–1237

Saha S, Pachon M, Ghoshal A and Schulz M 2004 Finite element modeling and optimization to prevent wire breakage in electro-discharge machining. Mechanics Research Communications. 31: 451–463

Habib S and Okada A 2016 Study on the movement of wire electrode during fine wire electrical discharge machining process. Journal of Materials Processing Technology. 227: 147–152

Vishwakarma U, Dvivedi A and Kumar P 2012 FEA modeling of material removal rate in electrical discharge machining of Al6063/SiC composites International Journal of Mechanical and Aerospace Engineering.6: 398–403

Yeo S, Kurnia W and Tan P 2007 Electro-thermal modelling of anode and cathode in micro-EDM. Journal of Physics D: Applied Physics. 40: 2513

Shabgard M, Seyedzavvar M, Oliaei S and Ivanov A 2011 A numerical method for predicting depth of heat affected zone in EDM process for AISI H13 tool steel. Journal of Scientific and Industrial Research. 70: 493–499

Mohapatra K 2016 Thermal Modeling and Structural Analysis in wire EDM Process for a 3D model. Applied Mechanics and Materials. 852: 279–289

Singh M 2018 Thermal simulation of machining of alumina with wire electrical discharge. Journal of Mechanical Science and Technology. 32: 333–343

Kumar J 2020 Three-Dimensional Numerical Modelling of Temperature Profiles on theWire Electrode During Wire Electric Discharge Machining Process In: International Conference on Recent Innovations and Developments in Mechanical Engineering, Meghalaya

Das S and Joshi S 2018 Thermal Modeling and Simulation In: Proceedings of All India Manufacturing Technology, Design and Research 120-135

Bejan A 2013 Heat transfer. 3rd edn. John Wiley & Sons Inc, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohite, N.T., Patil, G.V. & Kallol, A.N. Performance enhancement in WEDM of nitronic-30 using latent heat energy. Sādhanā 47, 75 (2022). https://doi.org/10.1007/s12046-022-01852-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-022-01852-z