Abstract

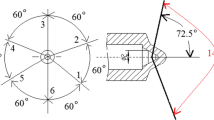

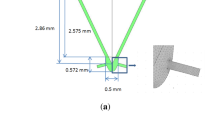

The non-circular diesel nozzles have influence on the inner cavitation and near-field spray patterns. For this investigation, two different non-circular diesel injectors with the same equivalent diameter were adopted. A detailed comparison of near-field spray and inner cavitation behaviors were investigated by using near-field spray experimental visualization method and numerical model. The elliptical nozzle has larger discharge coefficient, indicating that using the elliptical nozzle could increase the circulation ability. Also, the elliptical nozzle outlet has higher vorticity magnitude at all injection conditions than those of the circular nozzle. Besides, the cavitation is evenly distributed in the circular orifice inner wall. While for elliptical nozzle, the cavitation is mainly distributed along the major axis. Moreover, the near-field spray cone angle and projection area at the major axis of the elliptical nozzle are all wider than the circular nozzle. Because the nozzle exit turbulence vorticity and the cavitation along the major axis direction are both more intense than the circular nozzle, and these factors could increase the diffusion of the initial spray. Finally, it is possible to predict that the atomization quality of the elliptical spray is better than that of the circular spray from the larger spray cone angle and projected area of the near-field elliptical spray.

Similar content being viewed by others

References

Payri R, Salvador F, Gimeno J and De la Morena J 2009 Effects of nozzle geometry on direct injection diesel engine combustion process. Appl. Therm. Eng. 29(10): 2051–2060

Jung D, Wang W, Knafl A, Jacobs T, Hu S J and Assanis D 2008 Experimental investigation of abrasive flow machining effects on injector nozzle geometries, engine performance, and emissions in a DI diesel engine. Int. J. Autom. Technol. 9(1): 9–15

Payri R, Salvador F, Gimeno J and Viera J 2015 Experimental analysis on the influence of nozzle geometry over the dispersion of liquid n-dodecane sprays. Front. Mech. Eng. 1: 13

Yaliwal V, Banapurmath N, Gireesh N, Hosmath R, Donateo T and Tewari P 2016 Effect of nozzle and combustion chamber geometry on the performance of a diesel engine operated on dual fuel mode using renewable fuels. Renew. Energy 93: 483–501

Ma G, Tauzia X and Maiboom A 2014 One-dimensional combustion model with detailed chemistry for transient diesel sprays. Proc. Inst. Mech. Eng. Part D. J. Automob. Eng. 228(4): 457–476

Magno A, Mancaruso E and Vaglieco B M 2014 Experimental investigation in an optically accessible diesel engine of a fouled piezoelectric injector. Energy 64: 842–852

Payri R, Salvador F, Gimeno J and Zapata L 2008 Diesel nozzle geometry influence on spray liquid-phase fuel penetration in evaporative conditions. Fuel 87(7): 1165–1176

Cung K, Moiz AA, Shah B, Kalaskar V, Miwa J and Abidin Z 2019 Evaluation of Diesel Spray with Non-Circular Nozzle-Part I: Inert Spray. SAE Technical Paper, 01-0065

Yu S, Yin B, Deng W, Jia H, Ye Z and Xu B et al 2018 Internal flow and spray characteristics for elliptical orifice with large aspect ratio under typical diesel engine operation conditions. Fuel 228: 62–73

Salvador F, Jaramillo D, Romero J V and Roselló M D 2016 Using a homogeneous equilibrium model for the study of the inner nozzle flow and cavitation pattern in convergent–divergent nozzles of diesel injectors. J. Comput. Appl. Math. 309: 630–641

Macián V, Payri R, Margot X and Salvador F 2003 A CFD analysis of the influence of diesel nozzle geometry on the inception of cavitation. Atomiz. Sprays 13(5&6): 579–604

Payri R, Molina S, Salvador F and Gimeno J 2004 A study of the relation between nozzle geometry, internal flow and sprays characteristics in diesel fuel injection systems. KSME Int. J. 18(7): 1222–1235

Payri F, Payri R, Salvador F and Martínez-López J 2012 A contribution to the understanding of cavitation effects in Diesel injector nozzles through a combined experimental and computational investigation. Comput. Fluids 58: 88–101

Molina S, Salvador F, Carreres M and Jaramillo D 2014 A computational investigation on the influence of the use of elliptical orifices on the inner nozzle flow and cavitation development in diesel injector nozzles. Energy Convers. Manag. 79: 114–127

Hong J G, Ku K W and Lee C W 2011 Numerical simulation of the cavitating flow in an elliptical nozzle. Atomiz. Sprays 21(3): 237–248

Yu S, Yin B, Bi Q, Chen C and Jia H 2021 Experimental and numerical investigation on inner flow and spray characteristics of elliptical GDI injectors with large aspect ratio. Energy 224: 120119

Yu S, Yin B, Jia H, Chen C, Xu B 2021 Investigation of inner cavitation and nozzle exit flow patterns for elliptical orifice GDI injectors with various aspect ratios. Int. Commun. Heat Mass Transf. 129: 105682

Payri R, Gimeno J, Cuisano J and Arco J 2016 Hydraulic characterization of diesel engine single-hole injectors. Fuel 180: 357–366

Payri R, Garcia J, Salvador F and Gimeno J 2005 Using spray momentum flux measurements to understand the influence of diesel nozzle geometry on spray characteristics. Fuel 84(5): 551–561

Payri R, García-Oliver J M, Xuan T and Bardi M 2015 A study on diesel spray tip penetration and radial expansion under reacting conditions. Appl. Therm. Eng. 90: 619–629

He Z, Guo G, Tao X, Zhong W, Leng X and Wang Q 2016 Study of the effect of nozzle hole shape on internal flow and spray characteristics. Int. Commun. Heat Mass Transf. 71: 1–8

Yu S, Yin B, Deng W, Jia H, Ye Z and Xu B et al 2018 Experimental study on the spray characteristics discharging from elliptical diesel nozzle at typical diesel engine conditions. Fuel 221: 28–34

Yu S, Yin B, Deng W, Jia H, Ye Z and Xu B et al 2019 An experimental comparison of the elliptical and circular nozzles spray and mixing characteristics under different injection pressures. Fuel 236: 1474–1482

Hong J G, Ku K W, Kim S R and Lee C-W 2010 Effect of cavitation in circular nozzle and elliptical nozzles on the spray characteristic. Atomiz. Sprays 20(10): 877–886

Salvador F, Martínez-López J, Romero J-V and Roselló M-D 2013 Computational study of the cavitation phenomenon and its interaction with the turbulence developed in diesel injector nozzles by Large Eddy Simulation (LES). Math. Comput. Modell. 57(7–8): 1656–1662

Yuan W, Sauer J and Schnerr G H 2001 Modeling and computation of unsteady cavitation flows in injection nozzles. Méc. Ind. 2(5): 383–394

Yin B, Yu S, Jia H and Yu J 2016 Numerical research of diesel spray and atomization coupled cavitation by Large Eddy Simulation (LES) under high injection pressure. Int. J. Heat Fluid Flow 59: 1–9

Yu S, Yin B, Jia H, Wen S, Li X and Yu J 2017 Theoretical and experimental comparison of internal flow and spray characteristics between diesel and biodiesel. Fuel 208: 20–29

Yu S, Yin B, Deng W, Jia H, Ye Z and Xu B et al 2018 Computational analysis of flow patterns in elliptical diesel nozzles at high injection pressures. Atomiz. Sprays 28(11): 957–974

He Z, Zhong W, Wang Q, Jiang Z and Shao Z 2013 Effect of nozzle geometrical and dynamic factors on cavitating and turbulent flow in a diesel multi-hole injector nozzle. Int. J. Therm. Sci. 70: 132–143

He Z, Shao Z, Wang Q, Zhong W and Tao X 2015 Experimental study of cavitating flow inside vertical multi-hole nozzles with different length–diameter ratios using diesel and biodiesel. Exp. Therm. Fluid Sci. 60: 252–262

Andriotis A and Gavaises M 2009 Influence of vortex flow and cavitation on near-nozzle diesel spray dispersion angle. Atomiz. Sprays 19(3): 247–261

Guo G, He Z, Jin Y, Chen Z, Duan X, Leng X 2018 Visualization investigations of flow regimes in different sizes of diesel injector nozzles and their effects on spray. Atomiz. Sprays 28(6): 547–563

Desantes J, Payri R, Salvador F and De la Morena J 2010 Influence of cavitation phenomenon on primary break-up and spray behavior at stationary conditions. Fuel 89(10): 3033–3041

Payri R, Salvador F J, Gimeno J and Morena J D L 2009 Study of cavitation phenomena based on a technique for visualizing bubbles in a liquid pressurized chamber. Int. J. Heat Fluid Flow 30(4): 768–777

Shinjo J, Xia J and Umemura A 2015 Droplet/ligament modulation of local small-scale turbulence and scalar mixing in a dense fuel spray. Proc. Combust. Inst. 35(2): 1595–1602

Guo M, Nishida K, Ogata Y, Wu C and Fan Q 2017 Experimental study on fuel spray characteristics under atmospheric and pressurized cross-flow conditions, second report: spray distortion, spray area, and spray volume. Fuel 206: 401–408

Wang Z, Xu H, Jiang C and Wyszynski M L 2016 Experimental study on microscopic and macroscopic characteristics of diesel spray with split injection. Fuel 174: 140–152

Acknowledgements

This work was supported by Science and Technology on Scramjet Laboratory Project of China [STS/MY-KFKT-2017001]; Youth Program of National Natural Science Foundation of China [12002138]; Jiangsu provincial colleges of Natural Science General Program [21KJB460028]; Natural Science Foundation of Jiangsu Province [BK20201166]; The Priority Academic Program Development of Jiangsu Higher Education Institutions [PAPD].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, C., Yu, S., Yin, B. et al. Investigation of inner flow and near-field spray patterns of the non-circular diesel injector. Sādhanā 47, 34 (2022). https://doi.org/10.1007/s12046-022-01811-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-022-01811-8