Abstract

Soot blowers are employed in a predefined sequence and schedule to clean the ash particles on heat exchanger surface. However, considering the detrimental effects of frequent soot blow operation a criteria based system has to be adopted that involves soot blow activation based on a predefined cleanliness level. This insists the need for an online monitoring model to predict the Cleanliness Factor (CF). This paper analyzes the deposition of ash in power plant reheater with the objective of developing accurate prediction model for CF using Autoregressive Integrated Moving Average with eXplanatory variables (ARIMAX) model. In practice the covariates that should be included in the model is not known a priori and often with more number of candidate variables. The findings in this work reveal that the ARIMAX model including flue gas input temperature, 1 lag value of flue gas output temperatures, air flow rate, coal flow rate and attemperator flow rate in time series analysis of CF dataset produces a more robust predictive model. The model performance is quantified by two indicators namely and Root Mean Square Error (RMSE) and Akakie Information Criteria (AIC). To ensure the adequacy of the model residual diagnostics was performed which revealed that the Auto Correlation Function (ACF) plot of the residuals are uncorrelated and there is no considerable departure from white noise as the test statistic clearly shows that the p-values exceeds the 5% significance level for all lag orders. The recommendation suggested in this study can be applied to criteria based soot-blow operation where the soot blowers are operated when a predefined CF is reached.

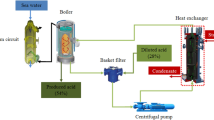

Source: NLC boiler manual.

Similar content being viewed by others

Abbreviations

- ACF:

-

Auto Correlation Function

- ARIMAX:

-

Autoregressive Integrated Moving Average with eXplanatory variables

- CF:

-

Cleanliness Factor

- NLC:

-

Neyveli Lignite Corporation

- PACF:

-

Partial Auto Correlation Function

- RMSE:

-

Root Mean Square Error

- A:

-

Heat transfer surface area (m2)

- c:

-

Specific heat capacity (J/kg/K)

- d:

-

Number of differencing in ARIMAX

- \(d\) :

-

Heat exchanger tube diameter

- h:

-

Convective heat transfer coefficient (W/m2K)

- M:

-

Mass of the fluid (kg)

- \({\dot{\text{m}}}\) :

-

Mass flow rate (kg/s)

- Nu:

-

Nusselt number (dimensionless)

- p:

-

Number of autoregressive terms in ARIMAX

- Pr:

-

Prandtl number (dimensionless)

- q:

-

Number of moving average terms in ARIMAX

- Re:

-

Reynolds number (dimensionless)

- Rf :

-

Thermal resistance (W/m2K)

- T:

-

Temperature of fluid (°C)

- U:

-

Overall heat transfer coefficient (W/m2K)

- {X}:

-

Independent variables of ARIMAX

- {Y}:

-

Dependent variable of ARIMAX

- \({{\alpha ,\beta ,\tau }}\) :

-

Model Parameters (dimensionless)

- μ:

-

Dynamic viscosity (kg/m/s)

- ρ:

-

Density of fluid (kg/m3)

- \(\kappa\) :

-

Thermal conductivity of fluid (W/mK)

- \({{\varphi }}\) :

-

Estimated coefficients of independent variable

- \(\delta\) :

-

Estimated constant of ARIMAX model

- \({\uptheta }\) :

-

Estimated coefficients of moving average term

- \(\xi\) :

-

Estimated coefficients of autoregressive term

- h:

-

Hot fluid or flue gas

- c:

-

Cold fluid or steam

- t:

-

Time

References

Sandberg J, Fdhila R B, Dahlquist E and Avelin A 2011 Dynamic simulation of fouling in a circulating fluidized biomass-fired boiler. Appl. Energy 88: 1813–1824

DiEz L I, Cortes C, Arauzo I and Valero A 2001 Combustion and heat transfer monitoring in large utility boilers. Int. J. Therm. Sci. 40: 489–496

Yan Q, Wang Y, Balezentis T, Sun Y and Streimikiene D 2018 Energy-Related CO2 Emission in China’s Provincial Thermal Electricity Generation: Driving Factors and Possibilities for Abatement. Energies 11: 1096

Han Y, Xu C, Xu G, Zhang Y and Yang Y 2017 An Improved Flexible Solar Thermal Energy Integration Process for Enhancing the Coal-Based Energy Efficiency and NOx Removal Effectiveness in Coal-Fired Power Plants under Different Load Conditions. Energies 10: 1485

Dong M, Han J, Li S and Pu H 2013 A Dynamic Model for the Normal Impact of Fly Ash Particle with a Planar Surface. Energies 6: 4288–4307

Dong M, Li S, Xie J and Han J 2013 Experimental Studies on the Normal Impact of Fly Ash Particles with Planar Surfaces. Energies 6: 3245–3262

Williams A 1994 Understanding slagging and fouling during PF combustion. Fuel 74: 1541

Bryers R W 1996 Fireside slagging, fouling, and high-temperature corrosion of heat-transfer surface due to impurities in steam-raising fuels. Prog. Energy Combust. Sci. 22: 29–120

Mohanty D K and Singru P M 2011 Use of C-factor for monitoring of fouling in a shell and tube heat exchanger. Energy 36: 2899–2904

Das R, Mishra S C, Ajith M and Uppaluri R 2008 An inverse analysis of a transient 2-D conduction–radiation problem using the lattice Boltzmann method and the finite volume method coupled with the genetic algorithm. J. Quant. Spectrosc. Radiative Transf. 109: 2060–2077

Das R, Mishra S C, Kumar T P and Uppaluri R 2011 An inverse analysis for parameter estimation applied to a non-fourier conduction–radiation problem. Heat Transf. Eng. 32: 455–466

Gogoi T K and Das R 2013 Inverse analysis of an internal reforming solid oxide fuel cell system using simplex search method. Appl. Math. Model. 37: 6994–7015

Gogoi T K and Das R 2014 A combined cycle plant with air and fuel recuperator for captive power application. Part 2: Inverse analysis and parameter estimation. Energy Convers. Manag. 79: 778–789

Gogoi T K, Pandey M and Das R 2015 Estimation of operating parameters of a reheat regenerative power cycle using simplex search and differential evolution based inverse methods. Energy Convers. Manag. 91: 204–218

Sarmah P, Gogoi T K and Das R 2017 Estimation of operating parameters of a SOFC integrated combined power cycle using differential evolution based inverse method. Appl. Thermal Eng. 119: 98–107

Makridakis S, Spiliotis E and Assimakopoulos V 2018 Statistical and Machine Learning forecasting methods: Concerns and ways forward. PLoS ONE 13: 1–26

Mohanraj M, Jayaraj S and Muraleedharan C 2015 Applications of artificial neural networks for thermal analysis of heat exchangers. Int. J. Thermal Sci. 90: 150–172

Radhakrishnan V R, Ramasamy M, Zabiri H, DoThanh V and Tahir N M 2007 Heat exchanger fouling model and preventive maintenance scheduling tool. Appl. Thermal Eng. 27: 2791–2802

Mohanty D K and Singru P M 2014 Fouling analysis of a shell and tube heat exchanger using local linear wavelet neural network. Int. J. Heat Mass Transf. 77: 946–955

Shi Y and Wang J 2015 Ash fouling monitoring and key variables analysis for coal fired power plant boiler. J. Thermal Sci. 19: 253–265

Pena B, Teruel E and Diez L I 2011 Soft-computing models for soot-blowing optimization in coal-fired utility boilers. Appl. Soft Comput. 11: 1657–1668

Degereji M U, Ingham D B, Ma L, Pourkashanian M and Williams A 2012 Prediction of ash slagging propensity in a pulverized coal combustion furnace. Fuel 101: 171–178

Brownlee J 2018 Deep Learning for Time Series Forecasting: Predict the Future with MLPs. 1st edn. Machine learning Mastery, New York

Jonsson G, Palsson O P and Sejling K 1992 Modelling and parameter estimation of heat exchangers-A statistical approach. J. Dyn. Syst. Meas. Control 114: 673–679

Sivathanu A K and Subramanian S 2018 Extended Kalman filter for fouling detection in thermal power plant reheater. Control Eng. Pract. 73: 91–99

Ashish M and Biao H 2002 Detection of abrupt change and applications in sensor decalibration monitoring. ISA Trans. 41: 155–166

Wand Y and Xu Y 2007 The application of ARIMAX model. Stat. Decis. 9: 1–11

Pihur V, Datta S and Datta S 2009 RankAggreg, an R package for weighted rank aggregation. BMC Bioinform. 23: 1607–1615

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sivathanu, A.K., Antonydass, A. Development of temporal model for analysis of heat transfer equipment subjected to fouling. Sādhanā 47, 24 (2022). https://doi.org/10.1007/s12046-021-01798-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-021-01798-8