Abstract

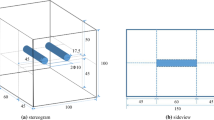

Chloride-induced steel reinforcing bars corrosion is a problem of worldwide importance because, in addition to massive industrialization, a majority of human population inhabit marine atmosphere zones where salinity is the main source of built infrastructure deterioration. Reinforced concrete structures vulnerable to chloride-induced corrosion potentially experience two stages of damage, namely non-structural and structural. Till date, with regard to non-uniform corrosion, there is very limited information regarding the significant role played by the non-structural stage of damage in influencing the progression of structural damage. The present work examines the process of non-uniform chloride ingress into concrete due to the existence of the steel bars and its influence on the spatial and temporal variations in the depth of corrosion penetration. Mathematical models in the form of Gaussian functions are proposed to represent space-time variation in corrosion initiation, spatial spread of corrosion penetration depth and corroded bar morphologies, and are compared with literature data. A numerical inverse analysis procedure is introduced to predict space-time evolution of non-structural damage from experimentally observed spatial spread of structural damage. Further, applicability of superposition approach for the evaluation of corrosion-induced stresses around the steel–concrete interface of a corner reinforcing bar is explored and shown to introduce spatial and temporal errors while evaluating structural damages.

Similar content being viewed by others

Abbreviations

- \( C_{d} \) :

-

cover depth (cm)

- \( d_{r} \) :

-

diameter of the original rebar (mm)

- \( d_{cr} \) :

-

corroding rebar diameter (mm)

- \( d_{cr}^{\hbox{min} } \) :

-

minimum diameter of the corroding rebar (mm)

- \( D_{{c,{\text{Ref}}}} \) :

-

reference chloride diffusion coefficient (m2/s)

- \( H_{env} \) :

-

relative humidity in the environment

- \( i_{\text{corr}} \) :

-

corrosion rate (μA/cm2)

- \( p_{d} \) :

-

corrosion penetration depth (mm)

- \( p_{d}^{a} \) :

-

corrosion penetration depth at \( a \) (mm)

- \( p_{d}^{b} \) :

-

corrosion penetration depth at \( b \) (mm)

- \( p_{d}^{\hbox{min} } \) :

-

minimum corrosion penetration depth (mm)

- \( p_{d}^{\hbox{max} } \) :

-

maximum corrosion penetration depth (mm)

- \( t \) :

-

exposure period (years)

- \( T_{i} \) :

-

time-to-corrosion initiation (years)

- \( T_{env} \) :

-

temperature in the environment (K)

- \( T_{\,i}^{\,1} \) :

-

time to first active corrosion (years)

- \( T_{\,i}^{\,\hbox{max} } \) :

-

maximum value of time-to-corrosion initiation (years)

- \( {w \mathord{\left/ {\vphantom {w b}} \right. \kern-0pt} b} \) :

-

water-to-binder ratio

- \( \theta_{a} \) :

-

angle between rebar center and \( a \) (degree)

- \( \theta_{b} \) :

-

angle between rebar center and \( b \) (degree)

- \( \theta_{\hbox{min} } \) :

-

minimum angle with rebar center (degrees)

- \( \theta_{\hbox{max} } \) :

-

maximum angle with rebar center (degrees)

- \( \kappa_{{\alpha_{L} }} \) :

-

binding isotherm constant (mL pore solution/g sample)

- \( \kappa_{{\beta_{L} }} \) :

-

binding isotherm constant (mL pore solution/mg Cl)

- \( \kappa_{{\alpha_{F} }} \) :

-

binding isotherm constant (mL pore solution/g sample)

- \( \kappa_{{\beta_{F} }} \) :

-

binding isotherm constant

- \( \eta_{1} \) :

-

regression coefficient

- \( \eta_{2} \) :

-

regression coefficient

- \( \lambda_{h} \) :

-

moisture diffusion coefficient

- \( \mu_{h} \) :

-

moisture diffusion coefficient

- \( \nu_{h} \) :

-

moisture diffusion coefficient

- \( \upsilon_{1} \) :

-

regression parameter

- \( \upsilon_{2} \) :

-

regression parameter

- \( \chi_{1} \) :

-

regression parameter

- \( \chi_{2} \) :

-

regression parameter

- \( \omega \) :

-

angular velocity (degree/year)

- \( \omega_{\hbox{max} } \) :

-

maximum angular velocity (degree/year)

References

Stewart M G and Suo Q H 2009 Extent of spatially variable corrosion damage as an indicator of strength and time-dependent reliability of RC beams. Eng. Struct. 31: 198–207

Bhargava K, Mori Y and Ghosh A K 2011 Time-dependent reliability of corrosion-affected RC beams – Part 1: Estimation of time-dependent strengths and associated variability. Nucl. Eng. Des. 241: 1371–1384

Tuutti K 1982 Corrosion of steel in concrete, Swedish Cement and Concrete Research Institute

Shafei B and Alipour A 2015 Application of large-scale non-Gaussian stochastic fields for the study of corrosion-induced structural deterioration. Eng. Struct. 88: 262–276

Marchand J and Samson E 2009 Predicting the service-life of concrete structures – Limitations of simplified models. Cement Concr. Compos.31: 515–521

Saetta A V, Scotta R V and Vitaliani R V 1993 Analysis of chloride diffusion into partially saturated concrete. ACI Struct. J. 90: 441–451

Martin-Perez B, Pantazopoulou S J and Thomas M D A 2001 Numerical solution of mass transport equations in concrete structures. Comput. Struct.79: 1251–1264

Andrade C and Alonso C 2001 On-site measurements of corrosion rate of reinforcements. Constr. Build. Mater. 15: 141–145

Angst U, Elsener B, Larsen C K and Vennesland O 2009 Critical chloride content in reinforced concrete – A review. Cem. Concr. Res.39: 1122–1138

Muthulingam S and Rao B N 2014 Non-uniform time-to-corrosion initiation in steel reinforced concrete under chloride environment. Corros. Sci.82: 304–315

Muthulingam S and Rao B N 2015 Numerical assessment of non-uniform corrosion scenarios of rebar in concrete exposed to natural chloride environment. Sadhana 40: 1313–1341

Oh B H and Jang B S 2003 Chloride diffusion analysis of concrete structures considering effects of reinforcements. ACI Mater. J.100: 143–149

Pantazopoulou S J and Papoulia K D 2001 Modeling cover-cracking due to reinforcement corrosion in RC structures. ASCE J. Eng. Mech.127: 342–351

Bhargava K, Ghosh A K, Mori Y and Ramanujam S 2003 Analytical model of corrosion-induced cracking of concrete considering the stiffness of reinforcement. Struct. Eng. Mech. 16: 749–769

Liu Y P and Weyers R E 1998 Modeling the time-to-corrosion cracking in chloride contaminated reinforced concrete structures. ACI Mater. J. 95: 675–681

Shafei B, Alipour A and Shinozuka M 2012 Prediction of corrosion initiation in reinforced concrete members subjected to environmental stressors: A finite‐element framework. Cem. Concr. Res. 42: 365–376

Otieno M, Beushausen H and Alexander M 2011 Prediction of corrosion rate in reinforced concrete structures – A critical review and preliminary results. Mater. Corros. 63: 777–790

Li C Q, Melchers R E and Zheng J J 2006 Analytical model for corrosion-induced crack width in reinforced concrete structures. ACI Struct. J. 103: 479–487

Val D V, Chemin L and Stewart M G 2009 Experimental and numerical investigation of corrosion-induced cover cracking in reinforced concrete structures. ASCE J. Struct. Eng. 135: 376–385

Chen D and Mahadevan S 2008 Chloride-induced reinforcement corrosion and concrete cracking simulation. Cement Concr. Compos. 30: 227–238

Zhao Y, Hu B, Yu J and Jin W 2011 Non-uniform distribution of rust layer around steel bar in concrete. Corros. Sci. 53: 4300–4308

Zhao Y X, Karimi A R, Wong H S, Hu B Y, Buenfeld N R and Jin W L 2011 Comparison of uniform and non-uniform corrosion induced damage in reinforced concrete based on a Gaussian description of the corrosion layer. Corros. Sci. 53: 2803–2814

Liu Y D and Li Y H 2004 Mechanistic model and numerical analysis for corrosion damage of reinforced concrete structure. Int. J. Fract. 126: 71–78

Baroghel-Bouny V, Thiéry M and Wang X 2011 Modelling of isothermal coupled moisture–ion transport in cementitious materials. Cem. Concr. Res. 41: 828–841

Muthulingam S and Rao B N 2015 Consistent models for estimating chloride ingress parameters in fly ash concrete. J. Buil. Eng. 3: 24–38

Tang L P and Nilsson L O 1993 Chloride binding-capacity and binding isotherms of opc pastes and mortars. Cem. Concr. Res. 23: 247–253

Xi Y P, Bazant Z P, Molina L and Jennings H M 1994 Moisture diffusion in cementitious materials – moisture capacity and diffusivity. Adv. Cem. Based Mater. 1: 258–266

Rodriguez J, Ortega L M, Casal J and Diez J M 1996 Corrosion of reinforcement and service life of concrete structures, Durability of Building Materials and Components 7, Stockholm, 117–126

Vu K A T and Stewart M G 2000 Structural reliability of concrete bridges including improved chloride-induced corrosion models. Struct. Saf. 22: 313–333

Japan Metereological Agency, http://www.data.jma.go.jp/obd/stats/data/en/normal/normal.html. Accessed 15 December 2015

Williamson S J and Clark L A 2000 Pressure required to cause cover cracking of concrete due to reinforcement corrosion. Mag. Concr. Res. 52: 455–467

Xia N, Ren Q W, Liang R Y, Payer J and Patnaik A 2012 Nonuniform corrosion-induced stresses in steel-reinforced concrete. ASCE J. Eng. Mech. 138: 338–346

Yuan Y S, Ji Y S and Mu Y J 2007 Propagation and model of distribution for corrosion of steel bars in concrete. China Civ. Eng. J. 40: 5–11

Zandi H K, Lundgren K, Plos M and Coronelli D 2013 Three-dimensional modelling of structural effects of corroding steel reinforcement in concrete. Struct. Infrastruct. Eng. 9: 702–718

Papakonstantinou K G and Shinozuka M 2013 Probabilistic model for steel corrosion in reinforced concrete structures of large dimensions considering crack effects. Eng. Struct. 57: 306–326

Acknowledgement

The support of Endeavour Research Fellowship from the Australian Government, Department of Education and Training is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Muthulingam, S. Space-time Gaussian models for evaluating corrosion-induced damages in reinforcing bars. Sādhanā 44, 13 (2019). https://doi.org/10.1007/s12046-018-1015-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-018-1015-7