Abstract

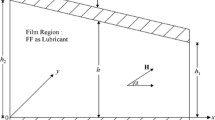

This paper presents an analytical study on the effect of couple stress on static and dynamic characteristics of wide tapered land slider bearing in the presence of applied magnetic field. A non-dimensional modified Reynolds equation is derived for the bearing under consideration. Closed-form expressions for the steady fluid film pressure, steady load carrying capacity and dynamic characteristics, viz., dynamic stiffness and dynamic damping coefficients are obtained. Numerical computations of the results revealed that magnetohydrodynamics tapered land slider bearing lubricated with couple stress fluid provides higher steady load carrying capacity, dynamic stiffness coefficient and dynamic damping coefficient as compared with the corresponding Newtonian case. It is observed that the presence of applied magnetic field characterized by the Hartmann number in the couple stress lubrication of tapered land slider bearing provides the improved static and dynamic characteristics as compared with the non-magnetic case.

Similar content being viewed by others

Abbreviations

- \( B_{0} \) :

-

applied magnetic field (Wb/m2)

- \( \bar{C}_{d} \) :

-

non-dimensional dynamic damping coefficient

- \( d \) :

-

difference between the inlet and outlet film thickness (m)

- \( F \) :

-

frictional force (N)

- \( \bar{F} \) :

-

non-dimensional frictional force, \( \bar{F} = \frac{{Fh_{ms}^{2} }}{{\mu UL^{2} B_{0} }} \)

- \( h(x,t) \) :

-

film thickness (m)

- \( \bar{h} \) :

-

non-dimensional film thickness, \( \bar{h}(\bar{x},\,\bar{t}) = h(x,\,t)/h_{ms} \)

- \( h_{m} (t) \) :

-

minimum squeezing film thickness (m)

- \( \bar{h}_{m} (\bar{t}) \) :

-

non-dimensional minimum squeezing film thickness \( \bar{h}_{m} (\bar{t}) = h_{m} (t)/h_{ms} \)

- \( h_{ms} \) :

-

steady-state reference minimum film thickness at outlet (m)

- \( h_{1} \) :

-

inlet film thickness (m)

- L :

-

length of the bearing (m)

- \( l \) :

-

couple stress parameter (m)

- \( \bar{l} \) :

-

non-dimensional couple stress parameter, \( \bar{l} = 2l/h_{ms} \)

- \( M \) :

-

Hartmann number, \( M = B_{0} h_{ms} \left( {\sigma /\mu } \right)^{1/2} \)

- \( p \) :

-

film pressure (Pa)

- \( p_{s} \) :

-

steady film pressure (Pa)

- \( \bar{p} \) :

-

non-dimensional film pressure, \( \bar{p} = ph_{ms}^{2} /\mu UL \)

- \( \bar{p}_{s} \) :

-

non-dimensional steady film pressure

- \( \bar{S}_{d} \) :

-

non-dimensional dynamic damping coefficient

- \( t,\,\bar{t} \) :

-

time, \( \bar{t} = Ut /L \) (s)

- U:

-

sliding velocity of lower part (m/s)

- \( \bar{V} \) :

-

non-dimensional squeezing velocity, \( \bar{V} = d\bar{h}_{m} /d\bar{t} \)

- u, w :

-

velocity components in x and z directions

- \( W_{s} \) :

-

steady load carrying capacity (N)

- \( \bar{W}_{s} \) :

-

non-dimensional steady load carrying capacity,

- x, z :

-

Cartesian coordinates

- \( \bar{x} \) :

-

non-dimensional coordinate \( \bar{x} = x /L \)

- \( \delta \) :

-

profile parameter \( \delta = d /h_{ms} \)

- \( \eta \) :

-

material constant responsible for couple stress parameter (Ns)

- \( \mu \) :

-

lubricant viscosity (Pa s)

- \( \sigma \) :

-

conductivity of the lubricant (mho/m)

References

Stokes V K 1966 Couple stresses in fluids. Phys. Fluids 9: 1709–1715

Sinha P and Singh C 1981 The effect of additives in the lubricant of a composite bearing with an inclined stepped surface. Wear 66: 17–26

Ramanaiah G and Sarkar P 1979 Slider bearings lubricated by fluids with couple stress. Wear 52: 27–36

Naduvinamani N B and Siddangouda A 2009 Squeeze film lubrication between circular stepped plates of couple stress fluids. J. Braz. Soc. Mech. Sci. Eng. 31: 21–26

Apparao S, Naduvinamani N B and Patil M D 2013 Lubrication characteristics of porous inclined stepped composite bearings with couple stress fluids. Tribol. Online 8: 234–241

Biradar T V 2013 Squeeze film lubrication between porous parallel stepped plates with couple stress fluids. Tribol. Online 8: 278–284

Naduvinamani N B, Apparao S, Gundayya H A and Biradar S N 2015 Effect of pressure dependent viscosity on couple stress squeeze film lubrication between rough parallel plates. Tribol. Online 10: 76–83

Hughes W F 1963 The magnetohydrodynamic inclined slider bearing with a transverse magnetic field. Wear 6: 315–324

Malik M and Singh D V 1980 Analysis of finite magnetohydrodynamic journal bearings. Wear 62: 273–280

Dudzinsky S J, Young F J and Hughes W F 1968 On the load carrying capacity of MHD journal bearing. J. Lubr. Technol. 90: 139–144

Das N C 1998 A study of optimum load-bearing capacity for slider bearings lubricated with couple stress fluids in magnetic field. Tribol. Int. 31: 393–400

Naduvinamani N B and Rajashekhar M 2011 MHD couple stress squeeze film characteristics between sphere and plane surface. Tribol. Mater. Surf. Interfaces 5: 94–99

Lin J R, Chu L M, Hung C and Wang P Y 2013 Derivation of two dimensional couple stress hydromagnetic squeeze film Reynolds equation and application to wide parallel rectangular plates. Meccanica 48: 253–258.

Fathima S T, Naduvinamani N B, Hanumagowda B N and Santoshkumar J 2015 Modified Reynolds equation for different types of finite plates with the combined effect of MHD and couple stresses. Tribol. Trans. 58: 660–667

Taylor C M and Dowson D 1974 Turbulent lubrication theory – application to design. ASME J. Lubr. Technol. 96: 36–46

Lin J R, Hung C R, Hsu C H and Lai C 2009 Dynamic stiffness and damping characteristics of one-dimensional magnetohydrodynamic inclined-plane slider bearings. Proc. Inst. Mech. Eng. J. J. Eng. Tribol. 223: 211–219

Lin J R, Lu R F, Ho M H and Lin M C 2006 Dynamic characteristics of wide tapered land slider bearings. J. Chin. Inst. Eng. 29: 543–548

Lin J R 2010 MHD steady and dynamic characteristics of wide tapered land slider bearings. Tribol. Int. 43: 2378–2383

Author information

Authors and Affiliations

Corresponding author

Appendix A

Appendix A

Rights and permissions

About this article

Cite this article

Naduvinamani, N.B., Siddangouda, A., Patil, S. et al. Effect of couple stresses on static and dynamic characteristics of MHD wide tapered land slider bearing. Sādhanā 43, 162 (2018). https://doi.org/10.1007/s12046-018-0940-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-018-0940-9