Abstract

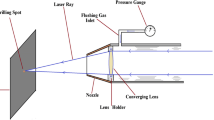

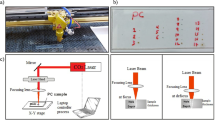

Laser drilling is a popular method as it eliminates the problem of chatter and vibration due to the absence of physical contact between the tool and workpiece. Tool breakage, a common phenomenon that occurs due to bending of the tool in making of slender holes using conventional drilling, can also be avoided. However, quality of the hole measured in terms of circularity, taper and spatter area is the major concern during laser drilling. The present investigation attempts to find out the optimum parametric setting during drilling of Ti6Al4V using CO2 laser in order to achieve quality holes. Experiments have been conducted to assess the influence of machining parameters, viz. flushing pressure, laser power and pulse frequency, on the performance characteristics such as taper of kerf, heat-affected zone (HAZ) and spatter area. Taguchi’s L9 orthogonal array has been used to design the experimental layout as it reduces the experimental cost and time. Analysis of variance has been performed to assess the effect of machining parameter on the performance characteristics. It has been observed that laser power has significant influence on taper of kerf, HAZ and spatter area. Based on desirability approach, the study suggests that all the performance characteristics can be simultaneously optimized at flushing pressure of 40 Pa, laser power of 2250 W and pulse frequency of 1600 Hz. The study also presents a numerical model to simulate the laser drilling process. Since comparison of experimental and numerical model shows a relative error within 10%, adequacy of the numerical model for assessment of quality characteristics of laser drilled holes is justified.

Similar content being viewed by others

References

Yeo C Y, Tam S C, Jana S and Lau M W 1994 A technical review of the laser drilling of aerospace materials. J. Mater. Process. Technol. 42(1): 15–49

Tansel I, Rodriguez O, Trujillo M, Paz E and Li W 1998 Micro-end-milling-I. Wear and breakage. Int. J. Mach. Tools Manuf. 38(12): 1419–1436

Bellows G and Kohls J 1982 Drilling without drills. American Mach. 126(3): 173–188

Chryssolouris G, Bredt J, Kordas S and Wilson E 1988 Theoretical aspects of a laser machine tool. J. Manuf. Sci. Eng. 110(1): 65–70

Low D K Y, Li L and Byrd P J 2000 The effects of process parameters on spatter deposition in laser percussion drilling. Opt. Laser Technol. 32(5): 347–354

Ghoreishi M, Low D K Y and Li L 2000 Comparative statistical analysis of hole taper and circularity in laser percussion drilling. Int. J. Mach. Tools Manuf. 42(9): 985–995

Brajdic M, Walther K and Eppelt U 2008 Analysis of laser drilled deep holes in stainless steel by superposed pulsed Nd: YAG laser radiation. Opt. Lasers Eng. 46(9): 648–655

Nagesh S, Narasimha Murthy H N, Krishna M and Basavaraj H 2013 Parametric study of CO2 laser drilling of carbon nano-powder/vinylester/glass nano-composites using design of experiments and grey relational analysis. Opt. Laser Technol. 48: 480–488

Shelton J A and Shin Y C 2010 Comparative evaluation of laser-assisted micro-milling for AISI 316, AISI 422, TI-6AL-4V and Inconel 718 in a side-cutting configuration. J. Micro-Mech. Micro-Eng. doi:10.1088/0960-1317/20/7/075012

Yan Y, Ji L, Bao Y and Jiang Y 2012 An experimental and numerical study on laser percussion drilling of thick-section alumina. J. Mater. Process. Technol. 212(6): 1257–1270

El-Taweel T A, Abdel-Maaboud A M, Azzam B S and Mohammad A E 2009 Parametric studies on the CO2 laser cutting of Kevlar-49 composite. Int. J. Adv. Manuf. Technol. 40(9–10): 907–917

Shuja S Z and Yilbas B S 2014 Flow and heat transfer characteristics of assisting gas impinging onto an alumina coated hole in relation to laser drilling. Opt. Laser Technol. 59: 123–130

Rozzi J C, Pfefferkorn F E, Incropera F P and Shin Y C 2000 Transient, three-dimensional heat transfer model for the laser assisted machining of silicon nitride: I. Comparison of predictions with measured surface temperature histories. Int. J. Heat Mass Transfer 43(8): 1409–1424

Rozzi J C, Pfefferkorn F E, Shin Y C and Incropera F P 2000 Experimental evaluation of the laser assisted machining of silicon nitride ceramics. J. Manuf. Sci. Eng. 122(4): 666–670

Yan Y, Li L, Sezer K, Whitehead D, Ji L, Bao Y and Jiang Y 2011 Experimental and theoretical investigation of fibre laser crack-free cutting of thick-section alumina. Int. J. Mach. Tools Manuf. 51(12): 859–870

Tsai C H and Chen H W 2003 Laser cutting of thick ceramic substrates by controlled fracture technique. J. Mater. Process. Technol. 136(1): 166–173

Bharatish A, Murthy H N, Anand B, Madhusoodana C D, Praveena G S and Krishna M 2013 Characterization of hole circularity and heat affected zone in pulsed CO2 laser drilling of alumina ceramics. Opt. Laser Technol. 53: 22–32

Dell’Erba M, Galantucci L M and Miglietta S 1992 An experimental study on laser drilling and cutting of composite materials for the aerospace industry using excimer and CO2 sources. Compos. Manuf. 3(1): 14–19

Aoyama E, Inoue H, Hirogaki T, Nobe H, Kitahara Y and Katayama T 1995 Study on small diameter drilling in GFRP. Compos. Struct. 32(1): 567–573

Hirogaki T, Aoyama E, Inoue H, Ogawa K, Maeda S and Katayama T 2001 Laser drilling of blind via holes in aramid and glass/epoxy composites for multi-layer printed wiring boards. Composites Part A: Appl. Sci. Manuf. 32(7): 963–968

Veniali F, Di Ilio A and Tagliaferri V 1995 An experimental study of the drilling of aramid composites. J Energy Resour. Technol. 117(4): 271–278

Derringer G 1980 Simultaneous optimization of several response variables. J. Qual. Technol. 12: 214–219

Sait A N, Aravindan S and Haq A N 2009 Optimisation of machining parameters of glass-fibre-reinforced plastic (GFRP) pipes by desirability function analysis using Taguchi technique. Int. J. Adv. Manuf. Tech. 43(5–6): 581–589

Pasandideh S H R and Niaki S T A 2006 Multi-response simulation optimization using genetic algorithm within desirability function framework. Appl. Math. Comput. 175(1): 366–382

Singh A, Datta S, Mahapatra S S, Singha T and Majumdar G 2013 Optimization of bead geometry of submerged arc weld using fuzzy based desirability function approach. J. Intel. Manuf. 24(1): 35–44

Datta S, Bandyopadhyay A and Pal P K 2006 Desirability function approach for solving multi-objective optimization problem in submerged arc welding. J. Manuf. Sci. Prod. 7(2): 127–138

Jin D and Lin S 2012 Advances in electronic commerce, web application and communication. Wuhan: Springer

Jeong I J and Kim K J 2009 An interactive desirability function method to multiresponse optimization. Eur. J. Oper. Res. 195(2): 412–426

Aggarwal A, Singh H, Kumar P and Singh M 2008 Optimization of multiple quality characteristics for CNC turning under cryogenic cutting environment using desirability function. J. Mater. Process. Technol. 205(1): 42–50

Kim K J and Lin D K 2000 Simultaneous optimization of mechanical properties of steel by maximizing exponential desirability functions. J. R. Stat. Soc.: Series C (Appl. Stat.) 49(3): 311–325

Nyon K Y, Nyeoh C Y, Mokhtar M and Abdul-Rahman R 2012 Finite element analysis of laser inert gas cutting on Inconel 718. Int. J. Adv. Manuf. Technol. 60(9–12): 995–1007

Chen M F, Hsiao W T, Wang M C, Yang K Y and Chen Y F 2015 A theoretical analysis and experimental verification of a laser drilling process for a ceramic substrate. Int. J. Adv. Manuf. Technol. 81: 1–10

Negarestani R, Sundar M, Sheikh M A, Mativenga P, Li L, Li Z L, Chu P L, Khin C C, Zheng H Y and Lim G C 2010 Numerical simulation of laser machining of carbon-fibre-reinforced composites. Proc. Inst. Mech. Engineers Part B: J. Eng. Manuf. 224(7): 1017–1027

Ye H Z and Liu X Y 2005 Microstructure and tensile properties of Ti6Al4V/AM60B magnesium matrix composite. J. Alloys Compd. 402(1): 162–169

Hascalik A and Caydas U 2007 Electrical discharge machining of titanium alloy (Ti–6Al–4V). Appl. Surf. Sci. 253(22): 9007–9016

Kayali Y, Buyuksagis A, Gunes I and Yalcin Y 2013 Investigation of corrosion behaviors at different solutions of boronized AISI 316L stainless steel. Prot. Met. Phys. Chem. Surf. 49(3): 348–358

Reissig L, Volkl R, Mills M J and Glatzel U 2004 Investigation of near surface structure in order to determine process-temperatures during different machining processes of Ti6Al4V. Scr. Mater. 50(1): 121–126

Bandyopadhyay S, Gokhale H, Sarin Sundar J K, Sundararajan G and Joshi S V 2005 A statistical approach to determine process parameter impact in Nd: YAG laser drilling of IN718 and Ti-6Al-4V sheets. Opt. Lasers Eng. 43(2): 163–182

Adams Jr. C M and Hardway G 1965 Fundamentals of laser beam machining and drilling. IEEE Trans. Ind. Gen. Appl. IGA-1 (2): 90–96

Yilbas B S 1997 Parametric study to improve laser hole drilling process. J. Mater. Process. Technol. 70(1): 264–273

Prusa J M, Venkitachalam G and Molian P A 1999 Estimation of heat conduction losses in laser cutting. Int. J. Mach. Tools Manuf. 39(3): 431–458

Padhee S, Pani S and Mahapatra S S 2011 A parametric study on laser drilling of Al/SiCp metal–matrix composite. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 226(1): 76–91

Mishra S and Yadava V 2013 Prediction of hole characteristics and hole productivity during pulsed Nd: YAG laser beam percussion drilling. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 227(4): 494–507

Singh H and Kumar P 2004 Tool wear optimization in turning operation by Taguchi method. Ind. J. Eng. Mater. Sci. 11(1): 19–24

Haq A N, Marimuthu P and Jeyapaul R 2008 Multi response optimization of machining parameters of drilling Al/SiC metal matrix composite using grey relational analysis in the Taguchi method. Int. J. Adv. Manuf. Technol. 37(3–4): 250–255

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chatterjee, S., Mahapatra, S.S., Mondal, A. et al. An experimental study on drilling of titanium alloy using CO2 laser. Sādhanā 43, 131 (2018). https://doi.org/10.1007/s12046-018-0903-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-018-0903-1