Abstract

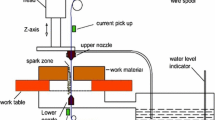

Inconel 625 is one of the most versatile nickel-based super alloy used in the aerospace, automobile, chemical processing, oil refining, marine, waste treatment, pulp and paper, and power industries. Wire electrical discharge machining (WEDM) is the process considered in the present text for machining of Inconel 625 as it can provide an effective solution for machining ultra-hard, high-strength and temperature-resistant materials and alloys, overcoming the constraints of the conventional processes. The present work is mainly focused on the analysis and optimization of the WEDM process parameters of Inconel 625. The four machining parameters, that is, pulse on time, pulse off time, spark gap voltage and wire feed have been varied to investigate their effects on three output responses, such as cutting speed, gap current, and surface roughness. Response surface methodology was used to develop the experimental models. The parametric analysis-based results revealed that pulse on time and pulse off time were significant, spark gap voltage is the least significant, and wire feed as a single factor is insignificant. Multi-objective optimization technique was employed using desirability approach to obtain the optimal parameters setting. Furthermore, surface topography in terms of machining parameters revealed that pulse on time and pulse off time significantly deteriorate the surface of the machined samples, which produce the deeper, wider overlapping craters and globules of debris.

Similar content being viewed by others

References

Dinda G P, Dasgupta A K and Mazumder J 2009 Laser aided direct metal deposition of Inconel 625 superalloy: microstructural evolution and thermal stability. Mater. Sci. Eng. A. 509(1–2): 98–104

Paul C P, Ganesh P, Mishra S K, Bhargava P, Negi J and Nath A K 2007 Investigating laser rapid manufacturing for Inconel-625 components. Opt. Las. Tech. 39(4): 800–805

Singh V K and Singh S 2015 Multi-objective optimization using Taguchi based Grey relational analysis for wire EDM of Inconel 625. J. Mater. Sci. Mech. Eng. 2(11): 38–42

Chopde I K, Gogte C and Milind D 2014 Modeling and optimization of WEDM parameters for surface finish using design of experiments. In: Proceedings of the International Conference on Industrial Engineering and Operations Management, Bali, Indonesia

Huang Yu, Ming Wuyi, Guo Jianwen, Zhang Zhen, Liu Guangdou, Li Mingzhen, and Zhang Guojun 2013 Optimization of cutting conditions of YG15 on rough and finish cutting in WEDM based on statistical analyses. Int. J. Adv. Manuf. Technol. 69(5): 993–1008

Akbar A L and Saeed D 2013 The effect of operational cutting parameters on Nitinol-60 in wire electrodischarge machining. Adv. Mater. Sci. Eng. 457186: 6. doi:10.1155/2013/457186

Zhang G, Zhang Z, Ming W, Guo J, Huang Yu and Shao X 2013 The multi-objective optimization of medium-speed WEDM process parameters for machining SKD11 steel by the hybrid method of RSM and NSGA-II. Int. J. Adv. Manuf. Technol. 70(9): 2097–2109

Narendranath S, Manjaiah M, Basavarajappa S and Gaitonde V N 2013 Experimental investigations on performance characteristics in wire electro discharge machining of Ti50Ni42.4Cu7.6 shape memory alloy. Proc. I. Mech. Eng. Part B: J. Eng. Manuf. 227(8):1180–1187

Gupta K and Jain N K 2014 Analysis and optimization of surface finish of wire electrical discharge machined miniature gears. Proc. I. Mech. Eng. Part B: J. Eng. Manuf. 228(5): 673–681

Kumar Anish, Kumar Vinod and Kumar Jatinder 2013 Multi-response optimization of process parameters based on response surface methodology for pure Titanium using WEDM process. Int. J. Adv. Manuf. Technol. 68: 2645–2668

Taweel T El and Hewid A 2012 Parametric study and optimization of WEDM parameters for CK45 steel. Int. J. Adv. Eng. Appl. 1(4): 47–61

Garg R 2010 Effect of process parameters on performance measures of wire electrical discharge machining. Ph.D. Thesis, Mechanical Engineering Department National Institute of Technology, Kurukshetra, India

Sharma P, Chakradhar D and Narendranath S 2015 Multi-response optimization of WEDM process using hybrid approach while machining Inconel 625 superalloy. J. Mach. Form. Technol. 6(3–4): 1947–4369

Rodge M K, Sarpate S S and Sharma S B 2013 Investigation on process response and parameters in wire electrical discharge machining of Inconel 625. Int. J. Mech. Eng. Technol. 4(1): 54–65

Rajyalakshmi G and Venkata Ramaiah P 2013 Multiple process parameter optimization of wire electrical discharge machining on Inconel 825 using Taguchi grey relational analysis. Int. J. Adv. Manuf. Technol. 69: 1249–1262

Ramakrishna R and Karunamoorthy L 2008 Modeling and multi response optimization of Inconel-718 on machining of CNC WEDM process. J. Mater. Process. Technol. 207: 343–349

Newton T R, Melkote S N, Watkins T R, Trejo R M and Reister L 2009 Investigation of the effect of process parameters on the formation and characteristics of recast layer in wire-EDM of Inconel 718. Mater Sci. Eng. 513–514: 208–215

Hewidy M S, El-Taweel T A and El-Safty M F 2005 Modelling the machining parameters of wire electrical discharge machining of Inconel-601 using RSM. J. Mater. Process. Technol. 169: 328–336

Jain V K, Rao Sreenivasa P, Choudhary S K and Rajurkar K P 1991 Experimental investigations into traveling wire electrochemical spark machining (TW-ECSM) of composites. J. Manuf. Sci. Eng. 113(1): 75–84

Montgomery D C 2002 Design and analysis of experiments, 4th edition, New York: Wiley

Gunaraj V and Murugan N 1999 Application of response surface methodologies for predicting weld base quality in submerged arc welding of pipes. J. Mater. Process. Technol. 88: 266–275

Kwak J S 2005 Application of Taguchi and response surface methodologies for geometric error in surface grinding process. Int. J. Mach. Tool. Manuf. 45: 327–334

Kim Chang-Ho and Kruth J P 2001 Influence of the electrical conductivity of dielectric on WEDM of sintered carbide. KSME. 15(12): 1676–1682

Pandey P C and Shan H S 1980 Modern machining processes, 45th reprint 2012, New Delhi: Tata McGraw Hill

Derringer G and Suich R 1980 Simultaneous optimization of several response variables. J. Q. Technol. 12: 214–219

Kumar Anish, Kumar Vinod and Kumar Jatinder 2014 Microstructure analysis and material transformation of pure titanium and tool wear surface after wire electric discharge machining. Mach. Sci. Technol. 18 (1): 47–77

Acknowledgements

The authors acknowledge M. M. University Mullana-Ambala, Haryana, India, for providing the necessary WEDM set-up for experimentation. The authors are also thankful to Mr. Pawan for providing help in the laboratory.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

GARG, M.P., KUMAR, A. & SAHU, C.K. Mathematical modeling and analysis of WEDM machining parameters of nickel-based super alloy using response surface methodology. Sādhanā 42, 981–1005 (2017). https://doi.org/10.1007/s12046-017-0647-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12046-017-0647-3