Abstract

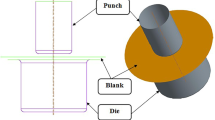

Process planning of sheet metal part is an important activity in the design of compound die. Traditional methods of carrying out this task are manual, tedious, time-consuming, error-prone and experience-based. This paper describes the research work involved in the development of an expert system for process planning of sheet metal parts produced on compound die. The proposed system is organized in six modules. For development of system modules, domain knowledge acquired from various sources of knowledge acquisition is refined and then framed in form of ‘IF-Then’ variety of production rules. System modules are coded in AutoLISP language and user interface is created using visual basic (VB). The system is capable to automate various activities of process planning including blank modeling, blank nesting, determining punch force required, selection of clearance between punch and die, identifying sheet metal operations, and determining proper sequence of operations for manufacturing the part. The proposed system can be implemented on a PC having VB and AutoCAD software, therefore its low cost of implementation makes it affordable even for small scale sheet metal industries.

Similar content being viewed by others

References

Naranje V and Kumar S 2010 AI applications to metal stamping die design – A review. World Acad. Sci. Eng. Technol. 44: 1526–1532

Kumar S and Singh R 2004 A low cost knowledge base system framework for progressive die design. J. Mater. Process. Technol. 153–154: 958–964

Xiao X, Chen S, Wang G and Xiao J 1990 An expert system for process planning for drawing. Adv. Tech. Plast. 1: 545–549

Hoffmann M, Geifiler U and Geiger M 1992 Computer-aided generation of bending sequences for die-bending machines. J. Mater. Process. Technol. 30: 1–12

Fang X D and Tolouei-Rad M 1994 Rule-based deep-drawing process planning for complex circular shells. Eng. Appl. Artif. Intell. 7: 395–405

Jin Z, Luo S and Daniel Fang X 2001 KBS-aided design of tube bending processes. Eng. Appl. Artif. Intell. 14: 599–606

Kang S S and Park D H 2002 Application of computer-aided process planning system for non-axisymmetric deep drawing Products. J. Mater. Process. Technol. 124: 36–48

Shi X, Chen J, Peng Y and Ruan X 2002 Development of a knowledge-based process planning system for an auto panel. Int. J. Adv. Manuf. Technol. 19: 898–904

Hussein H M A and Kumar S 2008 A computerized retrieval system for sheet metal parts. Asian Int. J. Sci. Technol. Prod. Manuf. 1: 31–40

Tsai Y L, You C F, Lin J Y and Liu K Y 2010 Knowledge-based engineering for process planning and die design for automotive panels. Comput.-Aided Des. Appl. 7: 75–87

Potocnik D, Pesan B, Balic J and Ulbin M 2011 Intelligent system for the automatic calculation of stamping parameters. Adv. Prod. Eng. Manag. 6: 129–137

Potocnik D, Ulbin M and Dolsak B 2012 Knowledge based system for supporting the design of a plate-press. J. Comput. Inf. Sci. Eng. 12: 1–5

Naranje V and Kumar S 2013 A knowledge-based system for strip-layout design for progressive deep drawing dies. Int. J. Comput. Appl. Technol. 48: 222–234

Boljanovic V and Paquin J R 2006 Die design fundamental. Industrial Press Inc, New York

Jones F D 1944 Die design and die making practice. The Industrial Press, New York

Kumar S 2006 A contribution to the development of knowledge based system for intelligent design of progressive dies. PhD thesis, Maharshi Dyanand University, Rohtak, India

Smith D A 1990 Die design handbook. 3rd edn SME, New York.

Suchy I 2006 Handbook of die design. The McGraw-Hill Companies, New York

Acknowledgments

Authors thank all domain experts for providing expertise in the development of proposed expert system. Authors also acknowledge the sanction of the project on “Automation of design of compound dies for sheet metal industries” (File No. SB/S3/MMER/0061/2013) by the Science & Engineering Research Board (SERB), Department of Science and Technology (DST), Government of India, New Delhi.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Salunkhe, S., Panghal, D., Kumar, S. et al. An expert system for process planning of sheet metal parts produced on compound die for use in stamping industries. Sādhanā 41, 901–907 (2016). https://doi.org/10.1007/s12046-016-0521-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12046-016-0521-8