Abstract

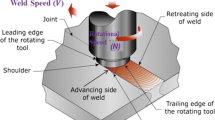

This paper proposes a new slip factor based three-dimensional thermal model to predict the temperature distribution during friction stir welding of 304L stainless steel plates. The proposed model employs temperature and radius dependent heat source to study the thermal cycle, temperature distribution, power required, the effect of process parameters on heat generation per mm length of the weld and peak temperature during the friction stir welding process. Simulations of friction stir welding process were carried out on 304L stainless steel workpieces for various rotational and welding speeds. The predicted thermal cycle, power required and temperature distributions were found to be in good agreement with the experimental results. The heat generation per mm length of weld and peak temperature were found to be directly proportional to rotational speed and inversely proportional to welding speed. The rate of increase in heat generation per mm length of the weld and peak temperature are found to be higher at lower rotational speeds and lower at higher rotational speed. The heat generation during friction stir welding was found to be 80.8 % at shoulder, 16.1 % at pin side and 3.1 % at the bottom of the pin.

Similar content being viewed by others

References

Buffa G, Hua J, Shivpuri R and Fratini L 2006 A continuum based fem model for friction stir welding—model development. Mater. Sci. Eng. A 419: 389–398

Chao Y J, Qi X and Tang W 2003 Heat transfer in friction stir welding-experimental and numerical studies. ASME J. Manuf. Sci. Eng. 125: 138–145

Chao Y J and Tang W 2003 Heat transfer in friction stir welding—experimental and numerical studies. Trans. ASME 125: 138–145

Chen Z, Pasang T and Qi Y 2008 Shear flow and formation of Nugget zone during friction stir welding of aluminium alloy 5083-O. Mater. Sci. Eng. A 474: 312–316

Dickerson T, Shi Q and Shercliff H R 2003 Heat flow into friction stir welding tools, 4 th International Symposium on Friction Stir Welding, Park City, Utah, 14–16

Durdanovic M B, Mijajlovic M M, Milcic D S and Stamenkovic D S 2009 Heat generation during friction stir welding process. Tribology in Industry 31: 11–21

Emam S A and Domiaty A E 2009 A refined energy-based model for friction-stir welding. World Academy of Sci. Eng. Technol. 53: 1016–1022

Hamilton C, Dymek S and Sommers A 2008 A thermal model of friction stir welding in aluminum alloys. Int. J. Machine Tools & Manuf. 48: 1120–1130

Hamilton C, Sommers A and Dymek S 2009 A thermal model of friction stir welding applied to Sc-modified Al–Zn–Mg–Cu alloy extrusions. Int. J. Machine Tools & Manuf. 49: 230–238

Lakshminarayanan A K, Balasubramanian V and Elangovan K 2009 Effect of welding processes on tensile properties of AA6061 aluminium alloy joints. Int. J. Advanced Manuf. Technol. 40: 286–296

Mokhtar A and Victor H M 2010 Energy generation during friction stir spot welding (FSSW) of Al 6061-T6 plates. Mater. Manuf. Processes 25: 167–174

Nandan R, Roy G G, Lienert T J and DebRoy T 2006 Numerical modelling of 3D plastic flow and heat transfer during friction stir welding of stainless steel. Sci. Technol. Welding and Joining 11: 526–537

Prasanna P, Rao B S and Mohana Rao G K 2010 Finite element modelling for maximum temperature in friction stir welding and its validation. Int. J. Advanced Manuf. Technol. 51: 925–933

Rajamanickam N, Balusamy V, Reddy G M and Natarajan K 2009 Effect of process parameters on thermal history and mechanical properties of friction stir welds. Mater. Design 30: 2726–2731

Riahi M and Nazari H 2010 Analysis of transient temperature and residual thermal stresses in friction stir welding of aluminum alloy 6061-T6 via numerical simulation. Int. J. Advanced Manuf. Technol. 55: 143–152

Schmidt H, Hattel J and Wert J 2004 An analytical model for heat generation in friction stir welding. Modelling simul. Mater. Sci. Eng. 12: 143–157

Song M and Kovacevic R 2003 Thermal modelling of friction stir welding in a moving coordinate system and its validation. Int. J. Machine Tools & Manuf. 43: 605–615

Soundararajan V, Zekovic S and Kovacevic R 2005 Thermo-mechanical model with adaptive boundary conditions for friction stir welding of Al 6061. Int. J. Machine Tools & Manuf. 45: 1577–1587

Woo W, Choo H, Withers P J and Feng Z 2009 Prediction of hardness minimum locations during natural aging in an aluminum alloy 6061-T6 friction stir weld. J. Mater. Sci. 44: 6302–6309

Zhang Z, Chen J T, Zhang Z W and Zhang H W 2011 Coupled thermo-mechanical model based comparison of friction stir welding processes of AA2024-T3 in different thicknesses. J. Mater. Sci. 46: 5815–5821

Zhu X K and Chao Y J 2004 Numerical simulation of transient temperature and residual stresses in friction stir welding of 304L stainless steel. J. Mater. Processing Technol. 146: 263–272

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

SELVARAJ, M. A temperature dependent slip factor based thermal model for friction stir welding of stainless steel. Sadhana 38, 1393–1405 (2013). https://doi.org/10.1007/s12046-013-0158-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12046-013-0158-9