Abstract

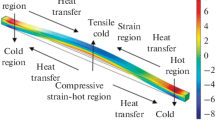

MEMS resonators are designed for a fixed resonant frequency. Therefore, any shift in the resonant frequency of the final fabricated structure can be a denting factor for its suitability towards a desired application. There are numerous factors which alter the designed resonant frequency of the fabricated resonator such as the metal layer deposited on top of the beam and the residual stresses present in the fabricated structure. While the metal coating, which acts as electrode, increases the stiffness and the effective mass of the composite structure, the residual stress increases or decreases the net stiffness if it is a tensile or compressive type respectively. In this paper, we investigate both these cases by taking two different structures, namely, the micro cantilever beam with gold layer deposited on its top surface and the MEMS gyroscope with residual stresses. First, we carry out experiments to characterize both these structures to find their resonant frequencies. Later, we analytically model those effects and compare them with the experimentally obtained values. Finally, it is found that the analytical models give an error of less than 10% with respect to the experimental results in both the cases.

Similar content being viewed by others

References

Bellout H, Neustupa J, Penel P 1999 Elastic properties and vibration of micro-machined structures subject to residual stresses. Proc. IEEE Canadian Conference on Electrical and Computer Engineering, 1674–1679

Chiou J C and Lin Y J 2005 A novel large displacement electrostatic actuator: Prestress comb drive actuator. J. Micromech. Microeng. 15: 1641–1648

Craighead H G 2000 Nanoelectromechanical systems. Science 290(5496): pp. 1532–1535

Fedder G K 1994 Simulation of microelectomechanical systems. Ph.D thesis, University of California.

Madou M 1997 Fundamentals of microfabrication, (Florida: CRC Press).

Maluf N 2000 Introduction to microelectromechanical systems engineering, (Boston: Artech house)

Pandey A K, Rudra Pratap, Venkatesh K P 2007 Effect of residual stress and perforations on the dynamic characterstics of MEMS devices. Proc. 1st National Conference of Research Scholars in Mechanical Engineering, India, 35–40

Polytec reference manual. URL: http://www.polytec.com

Rao S S 1995 Mechanical Vibrations, (New York: Wesley Publishing Company)

Senturia S D 2000 Microsystem Design, (Boston: Kluwer Academic Publishers)

Zhang X C, Xu B S, Wang H D, Wu Y X 2005 An analytical model for predicting thermal residual stresses in multilayer coating. J. Thin Solid Films 488: 274–282

Zhangt L M, Zhangt, Uttamchandanit D, Culshawt B, Dobson P 1990 Measurement of Young’s modulus and internal stress in silicon microresonators using a resonant frequency technique. Meas. Sci. Technol. 1: 1343–1346

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pandey, A.K., Venkatesh, K.P. & Pratap, R. Effect of metal coating and residual stress on the resonant frequency of MEMS resonators. Sadhana 34, 651–661 (2009). https://doi.org/10.1007/s12046-009-0029-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12046-009-0029-6