Abstract

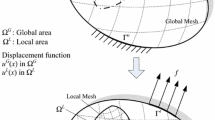

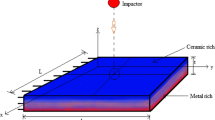

This paper presents a study on the effect of blow-holes on the reliability of a cast component. The most probable point (MPP) based univariate response surface approximation is used for evaluating reliability. Crack geometry, blow-hole dimensions, external loads and material properties are treated as independent random variables. The methodology involves novel function decomposition at a most probable point that facilitates the MPP-based univariate response surface approximation of the original multivariate implicit limit state/performance function in the rotated Gaussian space. Once the approximate form of the original implicit limit state/performance function is defined, the failure probability can be obtained by Monte Carlo simulation (MCS), importance sampling technique, and first- and second-order reliability methods (FORM/SORM). FORTRAN code is developed to automate calls to ABAQUS for numerically simulating responses at sample points, to construct univariate response surface approximation, and to subsequently evaluate the failure probability by MCS, importance sampling technique, and FORM/SORM.

Similar content being viewed by others

References

ABAQUS 2002 User’s Guide and Theoretical Manual, (Pawtucket, RI, USA: Hibbitt, Karlsson, and Sorenson, Inc.)

Anderson T L 2004 Fracture Mechanics: Fundamentals and Applications, second ed. (Boca Raton, Florida, USA: CRC Press Inc.)

Bjerager P 1988 Probability integration by directional simulation. ASCE J. Eng. Mech. 114(8):1285–1302

Breitung K 1984 Asymptotic approximations for multinormal integrals. ASCE J. Eng. Mech. 110(3):357–366

Debayeh A A, Xu R X, Du B P, Topper T H 1996 Fatigue of cast aluminium alloys under constant and variable-amplitude loading. Int. J. Fatigue 18: 95–104

Der Kiureghian A, Dakessian T 1998 Multiple design points in first and second-order reliability. Structural Safety 20(1): 37–49

Ditlevsen O, Madsen H O 1996 Structural Reliability Methods. (Chichester, UK: JohnWiley & Sons Ltd.)

Elena K 2002 Material defects in rolling contact fatigue — influence of overloads and defect clusters. Int. J. Fatigue 24: 887–894

Evans W J, Lu Z-J, Spittle J A, Devlukia J 1997 Fatigue crack development from defects in cast aluminium alloy. In: W O Soboyejo, T Srivatsan, (eds). High cycle fatigue of structural materials. The Minerals Metals and Materials Society 445–457

Hohenbichler M, Gollwitzer S, Kruse W, Rackwitz R 1987 New light on first- and second-order reliability methods. Structural Safety 4: 267–284

Cai G Q, Elishakoff I 1994 Refined second-order reliability analysis. Structural Safety 14: 267–276

Knott J F, Bowen P, Luo J, Jiang H, Sun H L 2000 The structural integrity of cast aluminium automotive components subjected to fatigue loads. Materials Science Forum 331–337: 1401–1412

Linder J, Axelsson M, Nilsson H 2006 The influence of porosity on the fatigue life for sand and permanent mould cast aluminium. Int. J. Fatigue 28: 1752–1758

Madsen H O, Krenk S, Lind N C 1986 Methods of Structural Safety. (Englewood Cliffs, NJ, USA: Prentice-Hall, Inc.)

Mayer H, Papakyriacou M, Zettl B, Stanz-Tschegg S E 2003 Influence of porosity on the fatigue limit of die cast magnesium and aluminium alloys. Int. J. Fatigue 25: 245–256

Nie J, Ellingwood B R 2000 Directional methods for structural reliability analysis. Structural Safety 22: 233–249

PATRAN 2005 MSC Software Corporation, Santa Ana, CA, USA

Rackwitz R 2001 Reliability analysis-A review and some perspectives. Structural Safety 23(4):365–395

Rahman S, Wei D 2006 A univariate approximation at most probable point for higher-order reliability analysis. Int. J. Solids and Struct. 43: 2820–2839

Skalleud B 1993 Fatigue life assessment of aluminium alloys with casting defects. Eng. Fracture Mech. 44(6): 857–74

Sonsino C M, Ziese J 1993 Fatigue strength and applications of cast aluminium alloys with different degree of porosity. Int. J. Fatigue 15: 75–84

Stanz-Tschegg S E, Mayer H R, Tschegg E K, Beste A 1993 In service loading of AlSi11 aluminium cast alloy in the very high cycle regime. Int. J. Fatigue 15: 311–316

Tvedt L 1990 Distribution of quadratic forms in normal space-application to structural reliability. ASCE J. Eng. Mech. 116(6): 1183–1197

Xu H, Rahman S 2004 A generalized dimension-reduction method for multi-dimensional integration in stochastic mechanics. Int. J. Numerical Methods in Eng. 61: 1992–2019

Xu H, Rahman S 2005 Decomposition methods for structural reliability analysis. Probabilistic Eng. Mech. 20: 239–250

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rao, B.N., Ashokkumar, R. Effect of blow-holes on reliability of cast component. Sadhana 33, 733–751 (2008). https://doi.org/10.1007/s12046-008-0031-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12046-008-0031-4