Abstract

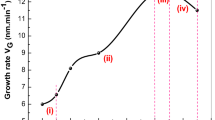

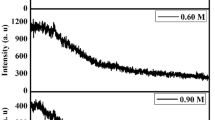

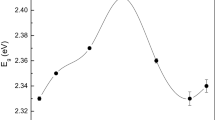

In this study, cadmium sulphide (CdS) thin layers are deposited at different deposition time periods (2.5, 3.5 and 5 h) on glass substrate by chemical bath deposition (CBD) technique at \(60^{\circ }\)C. The Seebeck effect, XRD and Raman spectra, SEM images and EDX analysis indicated the formation of n-type, amorphous nanograins, with relatively low sulphur deficiencies. The optical characterisations showed that the optical band gaps of the layers are varying in the range of 2.10–2.30 eV, as a result of band tail width originated from the sulphur vacancies acting as native donor-like levels distributed close to the conduction band edge, consistent with the EDX analysis. We also found that through the annealing treatments, the diameters of the nanograins are increased, the crystallinity of the layer has improved, and more importantly its electrical conductivity has largely increased (\(\sim \) 8 times), which is very important in CdS-related heterostructure photovoltaic applications.

Similar content being viewed by others

References

C Santiago Tepantlan, A M Perez Gonzalez and I Valeriano Arreola, Rev. Mex. Fis. 54, 112 (2008)

M Shaban, M Mustafa and A M El Sayed, Mater. Sci. Semicond. Process. 56, 329 (2016)

I C Chang and P Katzka, Opt. Lett. 7, 535 (1982)

M Isik, H H Gullua, S Delice, M Parlak and N M Gasanly, Mater. Sci. Semicond. Process. 93, 148 (2019)

S Arya, A Sharma, B Singh, M Riyas, P Bandhoria, M Aatif and V Gupta, Opt. Mater. 79, 115 (2018)

W Caseri, Macromol. Rapid Commun. 21, 705 (2000)

A Graf, N Maticiuc, N Spalatu, V Mikli, A Mere, A Gavrilov and J Hiie, Thin Solid Films 582, 351 (2015)

O H Abd-Elkader and A A Shaltout, Mater. Sci. Semicond. Process. 35, 132 (2015)

S N Sharma, R K Sharma, K N Sood and S Singh, Mater. Chem. Phys. 93, 368 (2005)

K S R K Rao and G Kumar, Energy Environ. Sci. 7, 45 (2014)

C Zhang, H Huo, Y Li, B Li and Y Yang, Mater. Lett. 102–103, 50 (2013)

R Devi, P Purkayastha, P K Kalita and B K Sarma, Bull. Mater. Sci. 30, 123 (2007)

S Ramesh and V Narayanan, Chem. Sci. Trans. 2, 192 (2013)

R W Birknoire, B E McCandles and S S Hegedus, Sol. Energy 12, 145 (1992)

M Isik, H H Gullu, S Delice, M Parlak and N M Gasanly, Mater. Sci. Semicond. Process. 93, 148 (2019)

P Raji, C Sanjeeviraja and K Ramachandra, Bull. Mater. Sci. 28, 233 (2005)

E M Feldmeier, A Fuchs, J Schaffner, H J Schimper, A Klein and W Jaegermann, Thin Solid Films 519, 7596 (2011)

J B Lee, S H Kwak and H J Kim, Thin Solid Films 423, 262 (2003)

M Maghouli and H Eshghi, Superlatt. Microstruct. 128, 327 (2019)

H Moualkia, S Hariech and M S Aida, Thin Solid Films 518, 1259 (2009)

Y Liu, T Tan, B Wang, R Zhai, X Song, E Li, H Wang and H Yan, J. Colloid Interface Sci. 320, 540 (2008)

S Yılmaz, Appl. Surf. Sci. 357, 873 (2015)

T J Ha, H H Park, S Y Jung, S J Yoon, J S Kim and H W Jang, Thin Solid Films 518, 7196 (2010)

S Ashrafabadi and H Eshghi, J. Mater. Sci. Mater. Electron. 29, 6470 (2018)

H Metin and R Esen, J. Cryst. Growth 258, 141 (2003)

H Zhan, J K Li and Y F Cheng, Optik 126, 1411 (2015)

P Q Zhao, L Z Liu, H T Xue, X L Wu, J C Shen and P K Chu, Appl. Phys. Lett. 102, 061910 (2013)

H Jerominek, M Pigeon, S Patela, Z Jakubczyk, C Delisle and R Tremblay, J. Appl. Phys. 63, 957 (1988)

S Aksay, M Polat, T Özer, S Köse and G Gürbüz, Appl. Surf. Sci. 257, 10072 (2011)

J Lee, Thin Solid Films 451–452, 170 (2004)

F Urbach, Phys. Rev. 92, 1324 (1953)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fekri, N., Eshghi, H. Effect of deposition time and annealing process in chemical bath deposited CdS thin film. Pramana - J Phys 95, 166 (2021). https://doi.org/10.1007/s12043-021-02204-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12043-021-02204-y