Abstract

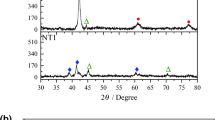

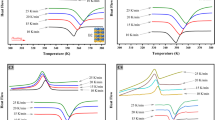

In this study, it is aimed to investigate the effects of NiTiCd alloy, which is formed by adding Cd element to NiTi shape memory alloys, on some physical and chemical parameters. The chemical compositions (% atomic) of the produced alloys were prepared as Ni48Ti50Cd2 and Ni46Ti50Cd4. Some thermodynamic parameters of these samples were investigated by DSC, structural analysis by SEM-EDX and XRD, hardness by Vickers microhardness method and corrosion behaviour by electrochemical method. The thermal activation energy required for phase transformations of alloys was calculated using the Kissinger and Ozawa methods. The average thermal activation energies obtained from the two methods are 85.76 kJ mol–1 for Ni48Ti50Cd2 SMA and 106.93 kJ mol–1 for Ni46Ti50Cd4 SMA. The XRD and SEM-EDX analyses indicated that the Ti element was the dominant constituent in the precipitate microstructures. It was found that with an increasing amount of cadmium, the microhardness of NiTi alloy decreases. It was calculated that Ni46Ti50Cd4 SMA has the best corrosion resistance compared to Ni48Ti50Cd2 alloys in terms of corrosion analysis.

Similar content being viewed by others

References

Balcı E and Dagdelen F 2022 Iran. J. Sci. Technol. Trans. A-Sci. 46 353

Jhou W-T, Wang C, Li S, Chiang H-S and Hsueh C-H 2018 J. Alloys Compd. 738 336

Wen C, Yu X, Zeng W, Zhao S, Wang L, Wan G et al 2018 AIMS Mater. Sci. 5 559

Rodrigue H, Wang W, Han M W, Kim T J and Ahn S-H 2017 Soft Robotics 7 727

Kalra S, Bhattacharya B and Munjal B 2017 Smart Mater. Struct. 26 095015

Dagdelen F, Balci E, Qader I, Aydogdu Y and Saydam S 2021 Phys. Met. Metallogr. 122 1572

Liu J and Guo Y 2015 Proc. Manuf. 1 904

Es-Souni M, Es-Souni M, Brandies F and H, 2005 Anal. Bioanal. Chem. 381 557

Mousavi T, Karimzadeh F and Abbasi M 2008 Mater. Sci. Eng. A 487 46

Ying C, Hai Chang J, Li Jian R, Li X and Xin Qing Z 2011 Intermetallics 19 217

Duerig T and Melton K EDP Sci. 7 191

Ohba T and Otsuka K 1996 MRS Online Proceedings Library 459 295

Murakami Y, Nakajima Y, Otsuka K, Ohba T, Matsuo R and Ohshima K 1997 Mater. Sci. Eng. A 237 87

Bernhoft R A 2013 Sci. World J. 7 2013

Feng R, Wei C, Tu S, Ding Y and Song Z 2013 Biol. Trace Elem. Res. 151 113

Hassanien A S and Akl A A 2016 Superlattice Microst. 89 153

Fujii H, Wang Y, Watanabe K, Sugiyama M and Nakano Y 2013 J. Appl. Phys. 114 103101

Huang C-H, Yang C-H, Shieh Y T and Wang T L 2018 J. Alloys Compd. 748 265

Hassanien A S, Neffati R and Aly K 2020 Optik 212 164681

Klaassen C D, Liu J and Diwan B A 2009 Toxicol. Appl. Pharmacol. 238 215

Genchi G, Sinicropi M S, Lauria G, Carocci A and Catalano A 2020 Int. J. Env. Res. Public Health 17 3782

Alharthi A, Hamza Z, Elmahdi M, Abuelzahab H and Saleh H 2020 Biol. Trace Elem. Res. 197 619

Organization W H 2019 World Health Organization 9 778

Hayat M T, Nauman M, Nazir N, Ali S and Bangash N 2019 Cadmium Toxic. Tol. Plants 30 71585

Genchi G, Carocci A, Lauria G, Sinicropi M S and Catalano A 2020 Int. J. Environ. Res. Public Health 17 679

Balci E, Dagdelen F, Qader I N and Kok M 2021 Eur. Phys. J. Plus. 136 145

Balci E and Dagdelen F 2022 J. Therm. Anal. Calorim. 46 353

Santosh S and Sampath V 2019 Trans. Indian Inst. Met. 72 1481

Dagdelen F, Balci E, Qader I N, Ozen E, Kok M, Kanca M S et al 2020 JOM 72 1664

Swaminathan G, Sampath V and Adarsh S 2021 Trans. Indian Inst. Met. 74 2435

Firstov G, Van Humbeeck J and Koval Y N 2006 J. Intell. Mater. Syst. Struct. 17 1041

Kus K and Breczko T 2010 Mater. Phys. Mech. 9 75

Dagdelen F and Aydogdu Y 2019 J. Therm. Anal. Calorim. 136 637

Balci E and Dağdelen F 2021 Int. J. Innov. Eng. Appl. 5 131

Dagdelen F, Balci E and Ercan E 2021 Bitlis Eren Unv. J. Sci. 10 796

Kissinger H E 1957 Anal. Chem. 29 1702

Ozawa T 1970 J. Therm. Anal. 2 301

Tillmann W and Momeni S 2015 Sens. Actuators A-Phys. 221 9

Li B, Rong L and Li Y 1999 Sci. China Ser. E 42 94

Oshida Y 2007 Biosci. Bioengin. Titanium Mater. 1 3

Dalvand R, Mahmud S and Seeni A 2019 J. Electron. Mater. 48 1604

Shi P, Cheng F and Man H C 2007 Mater. Lett. 61 2385

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Balci, E., Tatar, C., Tatar, B. et al. Effects of Cd addition to NiTi shape memory alloys on thermal, mechanical and corrosion behaviour. Bull Mater Sci 47, 54 (2024). https://doi.org/10.1007/s12034-023-03121-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-023-03121-z