Abstract

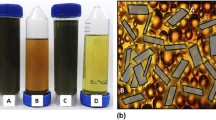

Graphene oxide is a diverse material for surface modification due to many –OH and –COOH groups present at terminal positions. This study reported the synthesis of nanoadditive from graphene oxide (GO) and hexadecanol (HD). The nanoadditive synthesized form was characterized by routine spectroscopic techniques like Fourier transform-infrared, X-ray diffraction and scanning electron microscopy. The thermal stability of a nanoadditive was further examined using thermogravimetric analysis. After confirming GO-HD formation, it was dispersed in mineral base oil (N-250) in three different compositions (0.2, 0.4 and 0.6% w/v) by ultrasonication method. The nanoadditives doped mineral oil was evaluated using standard ASTM methods for physicochemical analysis like kinematic viscosity, viscosity index and pour point. It was observed that GO-HD shows a considerable improvement in viscosity index and pour point at lower concentrations. Further, the resulting lubricant-doped GO-HD was also analysed for rheological and tribological analysis using Anton Paar MCR-72 and ASTM D4172 methods. It was observed that nanoadditives-doped lubricant exhibits non-Newtonian behaviour with respect to the base oil, whereas tribological results indicate a significant reduction in wear scar diameter ~9.5% and coefficient of friction ~11.8% as compared to the mineral base oil. Therefore, GO-HD nanoadditive shows multifunctional behaviour in terms of viscosity index, pour point, rheology and enhancement in antiwear and antifriction properties. The stable dispersion of chemically functionalized GO-HD provides low resistance sheared between the contacting surfaces due to the weak van der Waals interaction between their lamellas, thus significantly reducing both the friction and the wear.

Graphical abstract

Similar content being viewed by others

References

Ismail N A, Zulkifli N W M, Chowdhury Z Z and Johan M R 2021 Diam. Relat. Mater. 115 108357

Meurant G 1978 Tribology: A systems approach to the science and technology of friction, lubrication, and wear 1st edn. Elsevier

Hill Mc G 2007 McGraw-Hill concise encyclopedia of physics (USA: McGraw-Hill Companies)

Mang T and Dresel W 2007 Lubricants and lubrication 2nd edn. (Weinheim: John Wiley & Sons)

Geim A K and Novoselov K S 2009 Nat. Mater. 11

Geim A K 2009 Science 324 15300

Kim K S, Lee H J, Lee C, Lee S K, Jang H, Ahn J H et al 2011 ACS Nano 5 5107

Berman D, Deshmukh S A, Sankaranarayanan S K R S, Erdemir A and Sumant A V 2014 Adv. Funct. Mater. 24 6640

Bunch J S, Verbridge S S, Alden J S, Zande A M V D, Parpia J M, Craighead H G and McEuen P L 2008 Nano Lett. 8 2458 https://doi.org/10.1021/nl801457b

Paul G, Hirani H, Kuila T and Murmu N C 2019 Nanoscale 11 3458

Rasheed A K, Khalid M, Rashmi W, Gupta T C S M and Chan A 2016 Renew. Sustain. Energy Rev. 63 346

Chouhan A, Mungse H P and Khatri O P 2020 Adv. Colloid Interface Sci. 283 102215

Dreyer D R, Park S, Bielawski C W and Ruoff R S 2010 Chem. Soc. Rev. 39 228

Kim J, Cote L J, Kim F, Yuan W, Shull K R and Huang J 2010 J. Am. Chem. Soc. 132 8180

Ismail N A, Mohd Z, Nurin W, Chowdhury Z Z and Johan M R 2020 J. Mol. Liq. 319 114276

Quintana M, Vazquez E and Prato M 2013 Acc. Chem. Res. 46 138

Chua C K and Pumera M 2014 Chem. Soc. Rev. 43 291

Swain A K and Bahadur D 2014 J. Phys. Chem. C 118 9450

Salavagione H J, Gomez M A and Martínez G 2009 Macromolecules 42 6331

Cao Y, Lai Z, Feng J and Wu P 2011 J. Mater. Chem. 21 9271

Kou L, He H and Gao C 2010 Nano-Micro Lett. 2 177

Xue Y, Liu Y, Lu F, Qu J, Chen H and Dai L 2012 J. Phys. Chem. Lett. 3 1607

Zhuang X D 2010 Adv. Mater. 22 1731

An X, Simmons T, Shah R, Wolfe C, Lewis K M, Washimgton M et al 2010 Nano Lett. 10 4295

Avinash M, Subrahmanyam K S, Sundarayya and Govindaraju T 2010 Nanoscale 2 1762

Hu H, Wang X, Wang J, Liu F, Zhang M and Xu C 2011 Appl. Surf. Sci. 257 2637

Ismail N and Bagheri S 2017 Lubricants 5 30

Zhang W, Zhou M, Zhu H, Tian Y, Wang K, Wei J et al 2011 J. Phys. D Appl. Phys. 44 205303

Ou J, Wang J, Liu S, Mu B, Ren J, Wang H et al 2010 Langmuir 26 15830

Lin J, Wang L and Chen G 2011 Tribol. Lett. 41 209

Agarwal P, Chaudhary S, Porwal J, Singh R K and Porwal S K 2021 Polym. Bull. 79 2133

Singh N, Agarwal P, Porwal J and Porwal S K 2022 Biomass Conv. Bioref. https://doi.org/10.1007/s13399-022-02348-w

Agarwal P and Porwal S K 2021 Biomass Conv. Bioref. https://doi.org/10.1007/s13399-021-01336-w

Singh N, Agarwal P and Porwal S K 2022 Waste Biomass Valor. https://doi.org/10.1007/s12649-022-01745-6

Hummers W S and Offeman R E 1958 J. Am. Chem. Soc. 80 1339

Wang Y, Liu Z, Zhang T and Zhang Z 2017 Energy Technol. 5 2005

ASTM (2004) Standard practice for calculating viscosity index from kinematic viscosity at 40° and 100° ASTM standard D 2270, Annual book of ASTM standard. ASTM International, West Conshohocken, PA

Mousavi S B, Heris S Z and Stellé P E 2020 Sci Rep. 10 1

Chouhan A, Mungse H P, Sharma O P, Singh R K and Khatri O P 2018 J. Colloid Interface Sci. 513 666

Mungse H P and Khatri O P 2014 J. Phys. Chem. C 118 14394

Acknowledgement

We acknowledge CSIR-IIP, Dehradun, for extending the support in molecular characterization. We also thank Dr. Sandeep Porwal from CSJM University Kanpur and Dr. Nitin Kamboj from DIT University Dehradun for statistical analysis. Further, we thank DIT University for the award of research fellowship to Priyanka Agarwal.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Agarwal, P., Porwal, J., Singhal, N. et al. Chemically modified graphene oxide with fatty alcohol as antiwear, antifriction and rheology modifier for lubricating oil. Bull Mater Sci 45, 243 (2022). https://doi.org/10.1007/s12034-022-02833-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-022-02833-y