Abstract

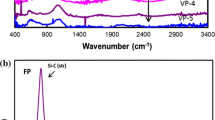

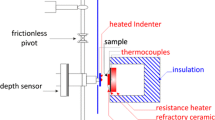

Silicon carbonitride (SiCN) thin films were deposited on p-Si (100) substrates with different \(\hbox {N}_{2}\) flow rates using SiC and \(\hbox {Si}_{3}\hbox {N}_{4}\) powder precursors by chemical vapour deposition. To investigate the structural, vibrational and mechanical properties, the SiCN thin films were characterized by atomic force microscopy, Raman spectroscopy, X-ray diffraction (XRD), Fourier transform infrared and nanoindentation techniques. The XRD results reveal nanocrystals embedded with amorphous networks in the SiCN thin films. An increase in the \(I_{\mathrm{D}}/I_{\mathrm{G}}\) ratio with an increase in the \(\hbox {N}_{2}\) flow rate indicated the increase of \(\hbox {sp}^{3}\) bonds in the SiCN thin film. The hardness (H), Young’s modulus (E), plasticity index (H / E) and \((H^{3}/E^{2})\) increase with an increase in the \(\hbox {N}_{2}\) flow rate.

Similar content being viewed by others

References

Bhattacharyya A S, Mishra S K and Mukherjee S 2010 J. Vac. Sci. Technol., A 28 505

Ma B, Wang Y, Wang K, Li X, Liu J and An L 2015 Acta Mater. 89 215

Cao Z X 2001 Thin Solid Films 401 94

Swain B P and Hwang N M 2008 Appl. Surf. Sci. 254 5319

Bhattacharyya A S and Mishra S K 2010 J. Micromech. Microeng. 21 015011

Kumar D and Swain B P 2019 J. Alloys Compd. 789 295

Reinold L M, Yamada Y, Graczyk-Zajac M, Munakata H, Kanamura K and Riedel R 2015 J. Power Sources 282 409

Ivashchenko V I, Porada O K, Ivashchenko L A, Timofeeva I I, Sinel’Nichenko O K, Butenko O O et al 2009 Powder Metall. Met. Ceram. 48 66

Sundaram K B, Alizadeh Z, Todi R M and Desai V H 2004 Mater. Sci. Eng. A 368 103

Hong B, Wu X M, Zhuge L J, Wu Z F and Zhou F 2010 Adv. Mater. Res. 97 1243

Porada A K, Kozak A O, Ivashchenko L A, Ivashchenko V I and Tomila T V 2013 Proc. of the International Conf. Nanomaterials: Applications and Properties, Odesa, Ukraine, 2013, 02FNC11-02FNC11

Kozak A O, Ivashchenkoa V I, Porada O K, Ivashchenko L A, Sinelnichenko O K, Dub S N et al 2015 J. Superhard Mater. 37 300

Rahman M A A, Tong G B, Mahmood M R, Siong C W, Yian H C and Rahman S A 2016 AIP Conf. Proc. 1784 040024

Ferrari A C and Robertson J 2000 J. Phys. Rev. B 61 14095

Bhattacharyya A S and Mishra S K 2010 J. Raman Spectrosc. 41 1234

Ferrari A C and Robertson J 2004 Philos. Trans. R. Soc. Lond. A: Math. Phys. Eng. Sci. 362 2477

Ferrari A C and Basko D M 2013 Nat. Nanotechnol. 8 235

Kalita K, Shivakoti I and Ghadai R K 2017 Mater. Manuf. Processes 32 1101

Mishra K K, Ghosh S, Ravindran T R, Amirthapandian S and Kamruddin M 2016 J. Phys. Chem. C 120 25092

Swain B P, Swain B S and Hwang N M 2014 J. Alloys Compd. 588 343

Awad Y, El Khakani M A, Aktik C, Mouine J, Camiré N, Lessard M et al 2009 Surf. Coat. Technol. 204 539

Wang L, Reehal H S, Martinez F L, San Andrés E and Del Prado A 2003 Semicond. Sci. Technol. 18 633

Wootton J L, Zink J I, Fleming G D and Vallette M C 1997 Inorg. Chem. 36 789

Ahn K, Kim K, Kim M and Kim J 2015 Ceram. Int. 41 2187

Schiavon M A, Soraru G D and Yoshida I V P 2002 J. Non-Cryst. Solids 304 76

Fainer N I, Kosyakov V I, Rumyantsev Y M, Maximovskii E A, Prokhorova S A and Gevko P N 2012 J. Struct. Chem. 53 812

Iwamoto Y, Völger W, Kroke E, Riedel R, Saitou T and Matsunaga K 2001 J. Am. Ceram. Soc. 84 2170

Swain B P 2009 S. Afr. J. Sci. 105 77

Oliver W C and Pharr G M 1992 J. Mater. Res. 7 1564

Liao F, Girshick S L, Mook W M, Gerberich W W and Zachariah M R 2005 Appl. Phys. Lett. 86 171913

Kulikovsky V, Vorlíček V, Boháč P, Kurdyumov A and Jastrabík L 2004 Diamond Relat. Mater. 13 1350

Vila M, Caceres D and Prieto C 2003 J. Appl. Phys. 94 7868

Walsh P, Omeltchenko A, Kalia R K, Nakano A, Vashishta P and Saini S 2003 Appl. Phys. Lett. 82 118

Ruffell S, Bradby J E, Williams J S and Munroe P 2007 J. Appl. Phys. 102 063521

Hu J Z, Merkle L D, Menoni C S and Spain I L 1986 Phys. Rev. B 34 4679

Leyland A and Matthews A 2000 Wear 246 1

Zhang S, Wang H L, Ong S E, Sun D and Bui X L 2007 Plasma Processes Polym. 4 219

Beake B D, Fox-Rabinovich G S, Veldhuis S C and Goodes S R 2009 Surf. Coat. Technol. 203 1919

Acknowledgements

The authors would like to express their special thanks to Prof Prita Pant, Department of Metallurgical Engineering and Materials Science, Indian Institute of Bombay (IIT Bombay) for conducting nanoindentation experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, D., Ghadai, R.K., Das, S. et al. Effect of nitrogen flow rate on the mechanical properties of CVD-deposited SiCN thin films. Bull Mater Sci 42, 251 (2019). https://doi.org/10.1007/s12034-019-1937-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-019-1937-7