Abstract

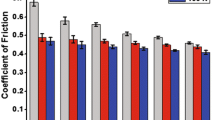

The main focus of this work is to improve the mechanical, wear and fatigue behaviours of polyoxymethylene (POM) by reinforcing with carbon nanotubes (CNTs). To improve compatibility between CNTs and POM, the surface of the CNTs was modified by various methods of functionalization like carboxylation, silanation, carbonylation and amination. The functionalized CNTs were characterized by Fourier transform infrared spectroscopy to confirm the different functional groups attached to the surface. POM/CNT nanocomposites were developed with functionalized CNTs in different concentrations varying from 0.25 to 2 wt%. Nanocomposites with 1 wt% of silanated CNTs resulted in maximum improvement of tensile, flexural and impact properties. Furthermore, experimental results on fatigue and dry sliding wear tests revealed that the fatigue strength, specific wear rate and friction coefficient are sensitive to functionalization and concentration of CNTs.

Similar content being viewed by others

References

Imrek H 2009 Tribol. Int. 42 503

Duzcukoglu H 2009 Tribol. Int. 42 1146

Ijima S 1991 Nature 354 56

Dresselhaus M S, Dresselhaus G and Saito R 1995 Carbon 33 883

Fiedeler B and Gojny F H 2006 Compos. Sci. Technol. 66 3115

Ma P-C, Siddique N A, Marom G and Kim J K 2010 Composites, Part A 41 1345

Yousef S, Visco A M, Galtieri G and Njuguna J 2016 J. Miner. Metals Mater. Soc. 68 288

Zeng Y, Ying Z, Du J and Cheng H M 2007 J. Phys. Chem. C 111 13945

Zhao X and Ye L 2010 J. Polym. Sci. B: Polym. Phys. 48 905. https://doi.org/10.1002/polb.21977

Wang F, Wu J K, Xia H S and Wang Q 2007 Plast. Rubber Compos. 36 297

Jiang Z, Chen Y and Liu Z 2014 J. Polym. Res. 21 451

Kwon J Y and Kim H D 2005 J. Appl. Polym. Sci. 96 595

Hong S-K, Kim D, Lee S, Kim B W, Theilmann P and Park S H 2015 Composites, Part A 77 142

Zhao C, Hu G, Justice R, Schaefer D W, Zhang S, Yang M et al 2005 Polymer 46 5125

Kim M-G, Moon J-B and Kim C-G 2012 Composites, Part A 43 1620

Ma P C, Kim J-K and Tang B Z 2007 Compos. Sci. Technol. 67 2965

Liu T, Tong Y and Zhang W-D 2007 Compos. Sci. Technol. 67 406

Meng H, Sui G X, Fang P F and Yang R 2008 Polymer 49 610

Yuen S-M, Ma Chen-Cchi M, Lin Yao Y and Kuan H-C 2007 Compos. Sci. Technol. 67 2564

Cui L-J, Geng H-Z, Wang W-Y, Chen L-T and Gao J 2013 Carbon 54 277

Sulong A B, Park J, Lee N and Goak J 2006 J. Compos. Mater. 40 1947

Lee J-H, Kathi J, Rhee K Y and Lee J H 2010 Polym. Eng. Sci. 50 1433

Zhang W, Picu R C and Koratkar N 2008 Nanotechnology 19 285709

Kuznetsova A, Mawhinney D B, Naumenko V, Yates J T, Liu J and Smalley R E 2000 Chem. Phys. Lett. 321 292

Satyanarayana N, Xie X and Rambabu B 2000 Mater. Sci. Eng. B 72 7

Lee J-H, Rhee K Y and Park S J 2011 Composites, Part A 42 478

Lazzeri A and Phuong V U 2014 Compos. Sci. Technol. 93 106

Zare Y 2015 Mech. Mater. 85 1

Saha S and Bal S 2017 Bull. Mater. Sci. 40 945

Saminathan K, Selvakumar P and Bhatnagar N 2008 Polym. Test. 27 453

Ghoshal S, Wang P H, Gulgunje P, Verghese N and Kumar S 2016 Polymer 100 259

Chandrasekaran S, Sato N, Tolle F, Mülhaupt R, Fiedler B and Schulte K 2014 Compos. Sci. Technol. 97 90

Wang P H, Sarkar S, Gulgunje P, Verghese N and Kumar S 2018 Polymer 151 287

Yuen S M, Ma C C M, Lin Y Y and Kuan H C 2007 Compos. Sci. Technol. 67 2564

Geng Y, Liu M Y, Li J, Shi X M and Kim J K 2008 Composites, Part A 39 1876

Mashhadzadeha A H, Fereidoona A B and Ahangari M G 2017 Appl. Surf. Sci. 420 167

Yang B X, Pramoda K P, Xu G Q and Goh S H 2007 Adv. Funct. Mater. 17 2062

Chang B-P, Md Akil H, Md. Nasir R B 2013 Wear 297 1120

Chand N and Dwivedi U K 2006 Wear 261 1057

Hwang W and Han K S 1986 J. Comp. Mater. 20 154

Acknowledgements

We gratefully acknowledge the financial support of the Department of Science and Technology, Government of India, for this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Goriparthi, B.K., Naveen, P.N.E., Ravi Sankar, H. et al. Effect of functionalization and concentration of carbon nanotubes on mechanical, wear and fatigue behaviours of polyoxymethylene/carbon nanotube nanocomposites. Bull Mater Sci 42, 98 (2019). https://doi.org/10.1007/s12034-019-1746-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-019-1746-z