Abstract

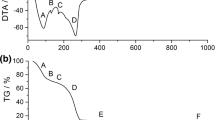

Mesoporous \(\upgamma \)-alumina was synthesized by the microwave-hydrothermal process with a shorter duration time at 150\({^{\circ }}\)C/2 h followed by calcination at 550\({^{\circ }}\)C/1 h. Ag nanoparticles (AgNPs) were impregnated into \(\upgamma \)-alumina under a reducing atmosphere at 450\({^{\circ }}\)C. The synthesized product was characterized by X-ray diffraction (XRD), thermogravimetric (TG)/differential thermal analysis (DTA), X-ray photoelectron spectroscopy (XPS), \(\hbox {N}_{2}\) adsorption–desorption study, field-emission scanning electron microscopy (FESEM) and transmission electron microscopy (TEM). The BET surface area values of \(\upgamma \)-alumina and Ag-impregnated \(\upgamma \)-alumina were found to be 258 and 230 m\(^{2}\) g\(^{-1}\), respectively. FESEM images showed the formation of grain-like particles of 50–70 nm in size with a flake-like microstructure. The XRD, XPS and TEM studies confirmed the presence of Ag in the synthesized product. Catalytic properties of the product for CO oxidation was studied with the \(T_{50}\) (50% conversion) and \(T_{100}\) (100% conversion) values of 118 and 135\({^{\circ }}\)C, respectively; the enhanced values were compared with the literature reported values.

Similar content being viewed by others

References

Tan H, Ma X and Fu M 2013 Bull. Mater. Sci. 36 153

Yang P, Zhao D, Margolese D I, Chmelka B F and Stucky G D 1998 Nature 396 152

Ghosh S, Dey K P and Naskar M K 2013 J. Am. Ceram. Soc. 96 28

Liu Q, Wang A, Wang X and Zhang T 2006 Chem. Mater. 18 5153

Tok A I Y, Boey F Y C and Zhao X L 2006 Mater. Process. Technol. 178 270

Parida K M, Pradhan A C, Das J and Sahu N 2009 Mater. Chem. Phys. 113 244

Li Y, Peng C, Li L and Rao P 2014 J. Am. Ceram. Soc. 97 35

Edrissi M and Norouzbeigi R 2011 J. Am. Ceram. Soc. 94 4052

Sivadasan A K, Selvam I P and Potty S N 2010 Bull. Mater. Sci. 33 737

Sommer W J and Weck M 2007 Langmuir 23 11991

Jones R A, Strickland J A, Stunkard J A and Siegel J 1971 Toxicol. Appl. Pharmacol. 19 46

Kou T, Lib D, Zhanga C, Zhanga Z and Yanga H 2014 J. Mol. Catal. A: Chem. 382 55

Townsend C L and Maynard R I 2002 Occup. Environ. Med. 59 708

Paldey S, Gedevanishvili S, Zhang W and Rasouli F 2005 Appl. Catal. B 56 241

Li Z X, Shi F B, Li L L, Zhang T and Yan C H 2011 Phys. Chem. Chem. Phys. 13 2488

Pillai U R and Deevi S 2006 Appl. Catal. B 64 146

Bose P, Ghosh S, Basak S and Naskar M K 2016 J. Asian Ceram. Soc. 4 1

Chen J L, Li J, Li H J, Huang X M and Shen W J 2008 Microporous Mesoporous Mater. 116 586

Tian D, Yong G P, Dai Y, Yan X Y and Liu S M 2009 Catal. Lett. 130 211

Frey K, Iablokov V, Melaet G, Guczi L and Kruse N 2008 Catal. Lett. 124 74

Yu L B, Shi Y Y, Zhao Z, Yin H B, Wei Y C, Liu J et al 2011 Catal. Commun. 12 616

Chowdhury I H, Ghosh S, Basak S and Naskar M K 2017 J. Phys. Chem. Solids 104 103

Wagner C D, Riggs W M, Davis L E, Moulder J F and Muilen-berg G E 1979 In Handbook of X-ray Photoelectron Spectroscopy (eds) Muilen-berg G E (Eden Prairie, MN: Perkin Elmer Corporation)

Chowdhury I H, Ghosh S and Naskar M K 2016 Ceram. Int. 42 2488

Mishra D, Annad S, Panda R K and Das R P 2002 Mater. Lett. 53 133

Naskar M K 2009 J. Am. Ceram. Soc. 92 2392

Abdalsayed V, Aljarash A, El-Shall M S, Othman Z A A and Alghamdi A H 2009 Chem. Mater. 21 2825

Zhang X D, Qu Z P, Li X Y, Wen M, Quan X, Ma D et al 2010 Sep. Purif. Technol. 72 395

Ji L, Lin J and Zeng H C 2000 J. Phys. Chem. B 104 1783

Rattan G and Kumar M 2014 Chem. Chem. Technol. 8 249

Grunwaldt J D, Kiener C, Wogerbauer C and Baiker A 1999 J. Catal. 181 223

Wang W H and Cao G Y 2006 Chin. J. Chem. 24 817

Kolodziejczyk M, Colen R E R, Berdau M, Delmon B and Block J H 1997 Surf. Sci. 375 235

Royer S and Duprez D 2011ChemCatChem 3 24

Bligaard T, Norskov J K, Dahl S, Matthiesen J, Christensen C H and Sehested J 2004 J. Catal. 224 206

Acknowledgements

The authors would like to thank the Director of CSIR-CGCRI for his kind permission to pursue this work. The author S.K., an AcSIR fellow, is grateful to CSIR, Government of India for her fellowship. The financial support from the Department of Science and Technology under the DST-SERB sponsored project, GAP 0616 (Grant No. SR/S3/ME/0035/2012), Government of India, is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kundu, S., Naskar, M.K. Microwave-hydrothermal synthesis of mesoporous \(\upgamma \)-\(\hbox {Al}_{2}\hbox {O}_{3}\) and its impregnation with AgNPs for excellent catalytic oxidation of CO. Bull Mater Sci 41, 161 (2018). https://doi.org/10.1007/s12034-018-1675-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-018-1675-2