Abstract

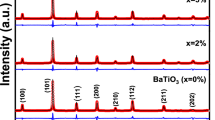

A 0.8PMN–0.2PT solid-solution ceramic was synthesized by columbite processing technique. The effects of sintering temperature on the density, structure and microstructure and in turn on the dielectric properties were investigated. The ceramics sintered at and above 1050\(^{\circ }\hbox {C}\) resulted in single-phase perovskite formation. However, high density >90% is achieved only after 1170\(^{\circ }\hbox {C}\). Microstructural analysis revealed that grain size increases with increase in sintering temperature. A significant increase in the peak of dielectric permittivity only after 1150\(^{\circ }\hbox {C}\) owing to increase in density is noted in this study. The quadratic law applied to this ceramic demonstrates that the transition is diffused. The broadness in phase transition and lower dielectric relaxation obtained for the composition demonstrate that the ceramic exhibits characteristics of both relaxor and normal ferroelectrics. The ceramic of composition 0.8PMN–0.2PT exhibits excellent dielectric properties \(\varepsilon _{\mathrm{r}\text {-}\mathrm{max}} =\) 20294−27338 at 100 Hz with \(T_{\mathrm{c}} = 100\)–\(96^{\circ }\hbox {C}\) at low sintering temperature 1170–1180\(^{\circ }\hbox {C}\), respectively.

Similar content being viewed by others

References

Yan M F, Ling H C and Rhodes W W 1987 J. Mater. Res. 4 930

Shrout T R and Halliyal A 1987 Am. Ceram. Soc. Bull. 66 704

Cross L E 1996 Mater. Chem. Phys. 43 108

Uršič H, Hrovat M, Holc J, Santo Zarnik M, Drnovšek S, Maček S et al 2008 Sens. Actuators B 133 699

King H W, Ferguson S H, Waechter D F and Prasad S E 2002 Proceedings of the 2nd Canada–US CanSmart Workshop, Montreal, Quebec, Canada p 11

Yamashita Y 1994 Jpn. J. Appl. Phys. 33 4652

Wongmaneerung R, Yimnirun R and Ananta S 2009 J. Mater. Sci. 44 5428

Hilton A D, Randall C A, Barber D J and Shrout T R 1989 Ferroelectrics 93 379

Chen J H and Liou Y-C 2004 Ceram. Int. 30 157

Ravindranathan P, Komarneni S, Bhalla A and Roy R J 1991 J. Am. Ceram. Soc. 74 2996

Liou Y-C and Wu L 1994 J. Am. Ceram. Soc. 77 3255

Elissalde C, Ravez J and Gaucher P 1994 Mater. Sci. Eng. B22 303

Sekar M M A and Halliyal A 1998 J. Am. Ceram. Soc. 81 380

Park J-H and Kim Y 1998 J. Korean Phys. Soc. 32 S967

Babooram K, Tailor H and Ye Z-G 2004 Ceram. Int. 30 1411

Ghasemifard M, Hosseini S M and Khorrami G H 2009 Ceram. Int. 35 2899

Tailor H N, Bokov A A and Ye Z-G 2011 IEEE Trans. Ultrason. Ferroelectr. 58 1920

Shrout T R, Chang Z P, Kim N and Markgraf S 1990 Ferroelectr. Lett. 12 63

Zuo R, Granzow T, Lupascu D C and Rodel J 2007 J. Am. Ceram. Soc. 90 1101

Yu S, Huang H, Zhou L and Ye Y 2008 J. Am. Ceram. Soc. 91 1057

Garcia J E, Guerra J D S, Araújo E B and Perez R 2009 J. Phys. D Appl. Phys. 42 115421

Zhai H-F, Tang R-L, Dong A, Guo H-R, Xia Y-D and Wu D 2009 J. Am. Ceram. Soc. 92 1256

Zhao S, Li Q, Feng Y and Nan C 2009 J. Phys. Chem. Solids 70 639

Zhang Y C, Yang Z Z, Ye W N, Lu C J and Xia L H 2011 J. Mater. Sci. Mater. Electron. 22 309

Zhao S-X, Li Q, Song F, Li C and Shen D 2007 Key Eng. Mater. 336–338 10

Lam K H, Li K and Chan H L W 2005 Mater. Res. Bull. 40 1955

Swartz S L and Shrout T 1982 Mater. Res. Bull. 17 1245

Guha J P, Hong D J and Anderson H U 1988 J. Am. Ceram. Soc. 71 C-152

Yoon K H, Ahn K P and Cho Y S 1993 Ferroelectrics 146 57

Sharma Y, Sil A and Yadav K L 2005 Indian J. Eng. Mater. Sci. 12 317

Fang B, Jiang N, Ding C, Du Q and Ding J 2012 Phys. Status Solidi A 209 254

Ding C, Fang B, Du Q and Zhou L 2010 Phys. Status Solidi A 207 979

Shaikh P A and Kolekar Y D 2012 J. Anal. Appl. Pyrolysis 93 41

Lejenue M and Biolot J P 1985 Mater. Res. Bull. 20 493

Xu G, Luo H, Wang P, Ql Z and Yin Z 2000 Chin. Sci. Bull. 45 1380

Gupta S M and Kulkarni A R 1996 J. Eur. Ceram. Soc. 16 473

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Takarkhede, M.V., Band, S.A. Synthesis, structural and dielectric properties of 0.8PMN–0.2PT relaxor ferroelectric ceramic. Bull Mater Sci 40, 917–923 (2017). https://doi.org/10.1007/s12034-017-1444-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-017-1444-7