Abstract

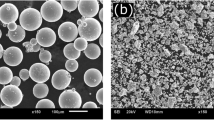

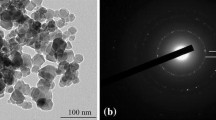

In the present study, Co–Cr–Mo/58S bioglass porous nano-composite samples were successfully produced using 30 wt% carbonate hydrogen ammonium and polyvinyl alcohol solution as space holder and binder, respectively. The cold compacted samples were heated at 175°C for 2 h and then were heated to sinter at 1100, 1150, 1200 and 1250°C for 3, 6, 9 and 12 h. True porosity of samples was measured and the samples were characterized using the X-ray diffraction (XRD) technique, scanning electron microscopy (SEM) and compressive test. Although the results of compression test for samples sintered at 1200 and 1250°C showed that the shape of stress–strain curves were similar to each other, compacted powders sintered at 1100 and 1150°C exhibited some fluctuations. Moreover, the compressive strength increased by decreasing the true porosity, indicating the role of high temperature on the sintering process. In addition, volume diffusion was predominant mechanism for these samples at sintering temperature of 1250°C. SEM images of the porous sample sintered at 1250°C for 3 h showed an appropriate range of pore sizes and interconnectivity. The XRD results showed that there are no contaminations and new phase is detectable in the sintered porous samples.

Similar content being viewed by others

References

Ping Li J, de Wijn J R, Van Blitterswijk C A and de Groot K 2006 Biomaterials 27 1223

Dourandish M, Godlinski D, Simchi A and Firouzdor V 2008 Mater. Sci. Eng. A 472 338

Giacchi J V, Morando C N, Fornaro O and Palacio H A 2011 Mater. Charact. 62 53

Lashgari H R, Zangeneh S., Hasanabadi F and Saghafi M 2010 Mater. Sci. Eng. A 527 4082

Greiner C, Oppenheimer S M and Dunand D C 2005 Acta Biomater. 1 705

Bansiddhi A and Dunand D C 2008 Acta Biomater. 4 1996

Krishna B V, Bose S and Bandyopadhyay A 2007 Acta Biomater. 3 997

Ye B and Dunand D C 2010 Mater. Sci. Eng. A 528 691

Jha N, Mondal D P, Majumdar J D, Badkul A, Jha A K and Khare A K 2013 Mater. Des. 47 810

Schneider E, Kinast C, Eulenberger J, Wyder D, Eskilsson G and Perren S M 1989 Clin. Orthop. Relat. Res. 248 200

Zhao Y Y and Sun D X 2001 Scr. Mater. 44 105

Ryan G, Pandit A and Apatsidis D P 2006 Biomaterials 27 2651

Xiong J Y, Li Y C, Wang X J, Hodgson P D and Wen C E 2008 J. Mech. Behav. Biomed. 1 269

Esen Z and Bor S 2007 Scr. Mater. 56 341

Balamurugan A, Sockalingum G, Michel J, Fauré J, Banchet V, Wortham L, Bouthors S, Laurent-Maquin D and Balossier G 2006 Mater. Lett. 60 3752

Gao Z, Li Q, He F, Huang Y and Wan Y 2012 Mater. Des. 42 13

Li Y H, Chen R B, Qi G X, Wang Z T and Deng Z Y 2009 J. Alloys Compd. 485 215

Mansourighasri A, Muhamad N and Sulong A B 2012 J. Mater. Process. Technol. 212 83

Ahmad S, Muhamad N, Muchtar A, Sahari J, Ibrahim M H I, Jamaludin K R and Nor N H M 2010 Int. J. Mech. Mater. Eng. 5 244

Dewidar M M and Lim J K 2008 J. Alloys Compd. 454 442

Waje S B, Hashim M, Yusoff W D W and Abbas Z 2010 Appl. Surf. Sci. 256 3122

Olevsky E A, Shoales G A and German R M 2001 Mater. Res. Bull. 36 449

Lenel F V 1964 Poroshk. Metall. 6 101

Rockland J G R 1967 Acta Met. 15 277

Hsu H C, Wu S C, Hsu S K, Chang T Y and Ho W F 2014 J. Alloys Compd. 582 793

Boer J D, Blitterswijk C V, Thomsen P, Hubbell J, Cancedda R, de Bruijn J D, Lindahl A, Sohier J and Williams D F 2008 In Tissue engineering (eds) D Hutmacher, T Woodfield, P Dalton and J Lewis (Canada: Academic Press)

Li J P, Habibovic P, van den Doel M, Wilson C E, de Wijn J R, Van Blitterswijk C A and de Groot K 2007 Biomaterials 28 2810

Xue W, Krishna B V, Bandyopadhyay A and Bose S 2007 Acta Biomater. 3 1007

Giacchi J V, Fornaro O and Palacio H 2012 Mater. Charact. 68 49

Hollander R and Wulff J 1975 J. Biomed. Mater. Res. 9 367

Mancha H, Carranza E, Escalante J I, Mendoza G, Mendez M, Cepeda F and Valdes E 2001 Metall. Mater. Trans. A 32A 979

Clemow A J and Daniell B L 1979 J. Biomed. Mater. Res. 13 265

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

DEHAGHANI, M.T., AHMADIAN, M. Effect of sintering temperature and time on the mechanical properties of Co–Cr–Mo/58S bioglass porous nano-composite. Bull Mater Sci 38, 1239–1246 (2015). https://doi.org/10.1007/s12034-015-1005-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-015-1005-x