Abstract

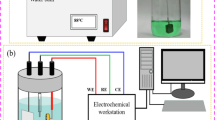

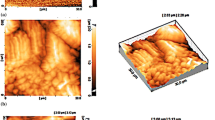

In this research, effect of surface mechanical attrition treatment (SMAT) was studied on characteristics of the coatings formed using plasma electrolyte oxidation (PEO) on AA1230 aluminium. To do so, first, the samples were coated with and without SMAT pre-process. Coating by PEO method was carried out in two phosphate-based and silicate-based suspensions of silicon nitride nanoparticles for 10 min. Next, to study the distribution of the nanoparticles and elements inside the coating, surface morphology of the samples was examined using scanning electron microscopy and energy dispersive spectroscopy. In addition, wettability test was performed on all samples using the deionized water. Also, droplet expansion manner on the porous oxide coating surface and its relation with fine structure of the coating was investigated. The results indicated that samples coated in silicate-based electrolyte have a relatively rougher microstructure as compared to samples coated in phosphate-based electrolyte. The average surface pores area percentage of the samples coated in silicate-based electrolytes was 13.9% greater than that of samples coated in phosphate-based electrolyte. Moreover, the average height to diameter (h/d) value obtained from wettability test for samples coated in silicate-based electrolyte was 13.3% greater than that of phosphate-based electrolyte.

Similar content being viewed by others

References

Etefagh R, Shahtahmasebi N and Karimipour M 2013 Bull. Mater. Sci. 36 411

Gupta G, Moon A P and Mondal K 2013 Bull. Mater. Sci. 36 51

Neelgund G M, Shivashankar S A, Chethana B K, Sahoo P P and Rao K J 2013, Bull. Mater. Sci. 34 1163

Saravanan M, Pillai R M, Pai B C, Brahmakumar M and Ravi K R 2006 Bull. Mater. Sci. 29 679

Cao Y, Wang Y B, Chen Z B, Liao X Z, Kawasaki M, Ringer S P et al 2013 Mater. Sci. Eng. A 578 110

Bonnot E, Helbert A L, Brisset F and Baudin T 2013 Mater. Sci. Eng. A 561 60

Kaune V and Muller C 2013 Mater. Sci. Eng. A 535 1

Chen A Y, Li D F, Zhang J B, Liu F, Liu X R and Lu J 2013 Mater. Sci. Eng. A 528 8389

Aliofkhazraei M, Rouhaghdam A S and Gupta P 2011 Crit. Rev. Solid State and Mater. Sci. 36 174

Yerokhin A L, Snizhko L O, Gurevina N L, Leyland A, Pilkington A and Matthews A 2003 J. Phys. D: Appl. Phys. 36 2110

Kim C W, Choi J H, Kim H J, Lee D W, Hyun C Y and Nam S M 2013 Ceram. Int. 38 5621

Shen M J, Wang X J and Zhang M F 2013 Appl. Surf. Sci. 259 362

Shin K R, Ko Y G and Shin D H 2013 J. Alloys Comp. 536 S226

Athauda T J, Williams W, Roberts K P and Ozer R R 2013 J. Mater. Sci. 48 6115

Li Z, Zheng Y, Zhao J and Cui L 2013 J. Thermal Spray Technol. 21 255

Psarski M, Celichowski G, Marczak J, Gumowski K and Sobieraj G B 2013 Surf. Coat. Tech. 225 66

Hao G, Guo Y, Liu G and Zhang X M 2013 Adv. Mater. Res. 105–106 67

Wen L, Wang Y, Jin Y and Sun D 2013 J. Phys.: Conf. Ser. 419

Zhang J and Hao G 2013 Adv. Mater. Res. 146–147 1821

Malayoglu U, Tekin K C and Shrestha S 2013 Surf. Coat. Technol. 205 1793

Sreekanth D, Rameshbabu N, Choudary K R and Rao K P 2013, Mater. Sci. Forum 710 683

Tarakci M 2013, Mater. Charact. 62 1214

Wang L, Chen L and Fu W 2013 Adv. Mater. Res. 168–170 1203

Lv G, Gu W, Chen H, Feng W, Khosa M L, Li L et al 2006 Appl. Surf. Sci. 253 2947

Wei-Chao G, Guo-Hua L, Huan C, Guang-Liang C, Wen-Ran F, Gu-Ling Z et al 2007 J. Mater. Process. Tech. 182 28

Aliofkhazraei M and Rouhaghdam A S 2012 Electrochem. Commun. 20 88

Matykina E, Arrabal R, Monfort F, Skeldon P and Thompson G E 2008 Appl. Surf. Sci. 255 2830

Necula B S, Fratila-Apachitei L E, Berkani A, Apachitei I and Duszczyk J 2009 J. Mater. Sci.: Mater. Med. 20 339

Necula B S, Apachitei I, Tichelaar F D, Fratila-Apachitei L E and Duszczyk J 2013 Acta Biomaterialia 7 2751

Bedi R S, Chow G, Wang J, Zanello L and Yan Y S 2013 Adv. Eng. Mater. 14 200

Kim C, Kendall M R, Miller M A, Long C L, Larson P R, Humphrey M B et al 2013 Mater. Sci. Eng. C 33 327

Sheng Y, Tang X and Xue J 2013 J. Mater. Chem. 22 1290

Thian E S, Chang L, Lim P N, Gurucharan B, Sun J, Fuh J Y H et al 2013 Surf. Coat. Tech. 231 29

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

MASIHA, H.R., BAGHERI, H.R., GHEYTANI, M. et al. Effect of nanocrystalline surface of substrate on microstructure and wetting of PEO coatings. Bull Mater Sci 38, 935–943 (2015). https://doi.org/10.1007/s12034-015-0924-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-015-0924-x