Abstract

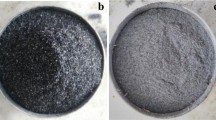

The aim of this paper is to investigate the effect of sintering temperature and time on the properties of Fe–Al2O3 composite (5 wt% Al2O3; 95 wt% Fe) prepared by powder metallurgy process. X-ray diffraction, microstructure, density, hardness and compressive strength of prepared samples have been investigated. XRD studies show the presence of Fe and Al2O3 along with iron aluminate phase. Iron aluminate is formed as a result of reactive sintering between iron and alumina particles. Microstructural examination of the specimen showed a dense structure with nanosize dispersion of the reinforcement of ceramic phase. Density as well as hardness of specimens depend on the formation of iron aluminate phase, which in turn depends on sintering temperature and time.

Similar content being viewed by others

References

Aldas K and Mat D M 2005 J. Mater. Proc. Technol. 160 289

Chen S H and Wang T C 2002 Acta Mechan. 157 113

Chua B W, Lu L and Lai M O 1999 Compos. Struct. 47 595

Fedorchenko I M and Ivanova I I 1969 Porosh. Metall. 84 23

Fligier A Wlodarczyk, Dobrzanski L A, Kremzer M and Adamiak M 2008 J. Achiev. Mater. Manuf. Engg. 27 99

Karak S K, Chudobab T, Witczak Z, Lojkowski W and Manna I 2011 Mater. Sci. Engg. A528 7475

Karak S K, Majumdar J Dutta, Lojkowski W, Michalski A, Ciupinski L, Kurzydłowski K J and Manna I 2012 Philos. Mag. 92 516

Konopka K and Ozieblo A 2001 Mater. Char. 46 125

Miracle D B 2005 Compos. Sci. Technol. 65 2526

Pagounis E, Talvitieb M and Lindroos V K 1996 Compos. Sci. Technol. 56 1329

Rabiei A, Vendra L and Kishi T 2008 Compos. Part A: Appl. Sci. Manuf. 39 294

Mehdi Rahimian, Naser Ehsani, Nader Parvin and Reza Baharvandi Hamid 2009 J. Mater. Proc. Technol. 209 5387

Reddy B S B, Rajasekhar K, Venu M, Dilip J J S, Das Siddhartha and Das Karabi 2008 J. Alloys Compd. 465 97

Rosso M 2006 J. Mater. Proc. Technol. 175 364

Roy D, Ghosh S, Basumallick A and Basu B 2006 Mater. Sci. Engg. A415 202

Shen Y L and Chawla N 2001 Mater. Sci. Engg. A297 44

Tjong S C and Ma Z Y 2000 Mater. Sci. Engg. 29 49

Torralba J M, Costa C E Da and Velasco F 2003 J. Mater. Proc. Technol. 133 203

Wei Yueguang 2001 Acta Mechan. Sinica 17 ISSN 0567-7718

Acknowledgements

The authors are thankful to Prof. G V S Sastry and late Prof. N Prasad, Department of Metallurgical Engineering, Indian Institute of Technology (Banaras Hindu University), Varanasi, for their valuable support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

GUPTA, P., KUMAR, D., PARKASH, O. et al. Structural and mechanical behaviour of 5% Al2O3-reinforced Fe metal matrix composites (MMCs) produced by powder metallurgy (P/M) route. Bull Mater Sci 36, 859–868 (2013). https://doi.org/10.1007/s12034-013-0545-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-013-0545-1