Abstract

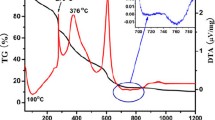

Although low temperature fast coprecipitation technique has been used to synthesize stoichiometric (MgO-nAl2O3, n = 1) MgAl2O4 spinel forming precursor, delayed spinellization has always been the concern in this process. In this article, the precursor of this ‘fast technique’ has been used for bulk production by further processing by high speed mixing with solvents and mechanical activation by attrition milling in terms of superior spinellization. At 1000°C, MgAl2O4 — γ-Al2O3 solid solution and MgO phases are formed (spinel formed by 1000°C is regarded as primary spinel). At higher temperatures, due to large agglomerate size, MgO can not properly interact with the exsolved α-Al2O3 from spinel solid solution to form secondary spinel; and consequently spinellization gets affected. Solvent treatment and attrition milling of the coprecipitated precursor disintegrate the larger agglomerates into smaller size (effect is more in attrition). Then MgO comes in proper contact with exsolved alumina, and therefore total spinel formation (primary + secondary) is enhanced. Extent of spinellization, for processed calcined samples where some alumina exists as solid solution with spinel, can be determined from the percentage conversion of MgO. Analysis of the processed powders suggests that the 4 h attrited precursor is most effective in terms of nano size (< 25 nm) stoichiometric spinel crystallite formation at ≤ 1100°C.

Similar content being viewed by others

References

Bratton R J 1969 Am. Ceram. Soc. Bull. 48 759

Cullity B D 1959 Elements of X-ray diffraction (USA: Addison-Wesley Publishing Company Inc.) p. 99

Flock W M 1978 Bayer-processed aluminas in ceramic processing before firing (eds) Onoda G Y Jr and Hench L L (New York: John Wiley & Sons) pp 85–100

Gusmano G, Nunziante P, Traversa E and Chiozzini G 1991 J. Eur. Ceram. Soc. 7 31

Hemanta Bhattacharya and Samaddar B N 1978 J. Am. Ceram. Soc. 61 279

Jing Shou-Yong, Lin Li-Bin, Huang Ning-Kang, Zhang Jin and Lu Yong 2000 J. Mater. Sci. Lett. 19 225

Katanic-Popovic, Miljevic N and Zec S 1991 Ceram. Int. 17 49

Mukherjee S G and Samaddar B N 1966 Trans. Ind. Ceram. Soc. 25 33

Paul P G and Samaddar B N 1984 Trans. Ind. Ceram. Soc. 43 154

Samaddar B N 1995 A novel process for preparing an inorganic bonding agent and commercially valuable products made therewith (Number 181525, India Patent, West Bengal)

Samaddar B N, Paul P G and Hemanta Bhattacharya 1979 Trans. Ind. Ceram. Soc. 38 151

Soumen Pal, Bandyopadhyay A K, Mukherjee S, Samaddar B N and Pal P G 2010 Bull. Mater. Sci. 33 451

Suwa Y, Roy R and Komarneni S 1986 Mater. Sci. Eng. 83 151

Zawrah M F 2004 Mater. Sci. Eng. A382 362

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pal, S., Bandyopadhyay, A.K., Mukherjee, S. et al. Enhancement of MgAl2O4 spinel formation from coprecipitated precursor by powder processing. Bull Mater Sci 34, 865 (2011). https://doi.org/10.1007/s12034-011-0207-0

Received:

Revised:

Published:

DOI: https://doi.org/10.1007/s12034-011-0207-0