Abstract

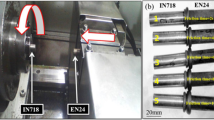

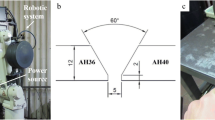

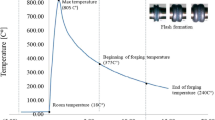

In this study, different welding parameters were applied to two different steels with high alloys and mechanical and metallographical investigations are performed. Thus, the optimum welding parameters were determined for these materials and working conditions. 12·30 diameter steel bars made up of 1·4871 (X53CrMnNiN219) and 1·4718 (X45CrSi93) steel were used as experimental material. The material loss increased with increase in friction and rotating pressure. No fracture at the welding region was observed and the highest fracture energy was identified in B5 group. Based on micro hardness investigation; the hardness profile reached its minimum value at the welding region.

Similar content being viewed by others

References

Alvise L D, Masoni E and Wallve S J 2002 J. Mater. Proc. Technol. 125 387

Anık S 1983 Welding technology (in Turkish), İstanbul pp. 259–269

Ateş H, Türker M and Kurt A 2007 Mater. Design 28 948

Bargel H J and Schulze G (Güleçş and Aran A) 1988 Materials (in Turkish), Gebze

Bayındır R and Ateş H 2007 J. Mater. Proc. Technol. 189 126

Bol’shokov M V 1972 The vacuum friction welding of high-melting and high-temperature alloys, auto welding pp 60–62

Chalmers R E 2001 Manuf. Eng. 126 64

Çelik S and Ersozlu I 2009 Mater. Design 30 970

Duffin F D and Crossland B 1971 Friction welding with sudden relase of the fixed component. Advances in welding processes, Solid phase joining processes, proceeding of the conference (Cambridge: The Welding Institute, Abington Hall) pp 25–33

Gooch, T G, Jones R L and Woolin P 1996 Welding processes for stainless steels (Sheet Metal Industrial Supplies) p. 5

Ishibashi A, Ezde S and Tanaka S 1983 Bull. JSME, 26 1080

Kato M, Kagaya C, Kawaguchi Y and Tokisue H 1996 Soc. Mech. Eng. 62 22

Lucas W 1971 Welding J. 7 293

Ochi H, Ogawa K, Yamamoto Y, Hashinaga S, Suga Y and Ohnishi T 1996 J. Japan Inst. Light Met. 46 500

Özdemir N 2005 Mater. Letts 59 2504

Özdemir N, Sarsılmaz F and Hasçalık A 2007 Mater. & Design 28 301

Ogawa K, Yamaguchi H, Kaga S and Sakaguchi K 1993 Trans. Japan Welding Soc. 24 47

Satyanarayana V V, Reddy G M and Mohandas T 2005 J. Mater. Process. Technol. 169 128

Sunay T Y, Sahin M and Altıntas S 2009 Int. J. Adv. Manuf. Technol., 44 68

Şahin A Z, Yilbas B S and Al-Garni A Z 1996 J. Mater. Eng. Perform. 5 89

Şahin M and Akata H E 2003 J. Mater. Process. Technol. 142 239

Şahin M 2004 J. Mater. Process. Technol. 153 1011

Şahin M 2005 J. Mater. Process. Technol. 168 202

Şahin M 2007 Mater. & Design 28 2244

Tanicheva O N, Orlova N E and Kyun L A 1989 Mater. Sci. & Heat Treatment 3 200

Tülbentçi K and Yılmaz M 1989 Solid state welding of different tool, II. Symposium of welding (in Turkish) (İstanbul: Istanbul Technical University) pp. 303–314

Tylecote R Y 1968 The solid phase welding of metals (London: Edward Arnold Ltd)

Uzkut M 1999 The determination of optimum welding parameters of high alloyed two different steels on joining by friction welding, Ph D thesis (in Turkish), Manisa

Voinov V P 1972 Welding Prod. 7 51

Vill V I 1962 Friction welding of metals (New York: AWS)

Welding Handbook 1980 AWS, Miami 58–76 239

Yılmaz M 1993 Investigation of welding zone different tool steels on friction welding, Ph D thesis (in Turkish), Y T Ü, İstanbul, pp. 1–55.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Uzkut, M., Ünlü, B.S. & Akdağ, M. Determination of optimum welding parameters in connecting high alloyed X53CrMnNiN219 and X45CrSi93 steels by friction welding. Bull Mater Sci 34, 815 (2011). https://doi.org/10.1007/s12034-011-0200-7

Received:

Revised:

Published:

DOI: https://doi.org/10.1007/s12034-011-0200-7