Abstract

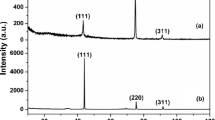

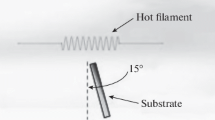

Polycrystalline diamond coatings are grown on Si (100) substrate by hot filament CVD technique. We investigate here the effect of substrate roughening on the substrate temperature and methane concentration required to maintain high quality, high growth rate and faceted morphology of the diamond coatings. It has been shown that as we increase the substrate roughness from 0.05 μm to 0.91 μm (centre line average or CLA) there is enhancement in deposited film quality (Raman peak intensity ratio of sp 3 to non-sp 3 content increases from 1.65 to 7.13) and the substrate temperature can be brought down to 640°C without any additional substrate heating. The coatings grown at adverse conditions for sp 3 deposition has cauliflower morphology with nanocrystalline grains and coatings grown under favourable sp 3 condition gives clear faceted grains.

Similar content being viewed by others

References

Amorim A, Nascente P A P, Trava-Airoldi V J, Corat E J, Alves A R and Moro J R 2009 Vacuum 83 1054

Butler J E and Woodin R L 1993 Philos. Trans. R. Soc. London A342 209

Butler J E and Sumant A V 2008 Chem. Vap. Depos. 14 145

Chang C P, Flamn D L, Ibbotson D E and Mucha J A 1988 J. Appl. Phys. 63 1744

Das D and Singh R N 2007 Int. Mater. Rev. 52 29

Gruen Dieter M 1999 Ann. Rev. Mater. Sci. 29 211

Feng Z, Komvipoulos K, Brown I G and Bogy D B 1993 J. Appl. Phys. 74 2841

Hirabayashi K et al 1988 Appl. Phys. Lett. 53 1815

Jansen F, Machonkin M A and Kuhman D E 1990 J. Vac. Sci. Technol. A8 3785

Kama M, Sato Y, Matsumoto S and Setaha N 1983 J. Cryst. Growth 62 642

Kobashi K, Nishimura K, Miyata K, Kumagai K and Nakaue A 1990 J. Mater. Res. 5 2469

Kondoh K, Ohta T, Mitomo T and Ohtsuka K 1994 Diam. Rel. Mater. 3 270

Lee S T, Lin Z and Jiang X 1999 Mater. Sci. & Eng. R25 123

Lin S J et al 1992 Appl. Phys. Lett. 60 1559

Matsumoto S 1982 J. Mater. Sci. 17 3106

Mitsuda K, Kojima Y, Yoshida T and Akashi K 1987 J. Mater. Sci. 22 1557

Narayan J, Godbole V P, Matera G and Singh R K 1992 J. Appl. Phys. 71 966

May Paul W 2000 Philos. Trans. R. Soc. London A358 473

Popovici Galina and Prelas M A 1992 Phys. Status Solidi 132 233

Sarangi S K, Chattopadhyay A and Chattopadhyay A K 2008 Appl. Surf. Sci. 254 3721

Shenderova O, Hens S and McGuire G 2010 Dia. Rel. Mater. 19 260

Stoner B R, Ma G H M, Wolter S D and Glass J T 1992 Phys. Rev. B45 11067

Suzulu K, Swabe A, Yasuda H and Inuzuka T 1995 Appl. Phys. Lett. 66 1900

Takahashi H, Kamiya S and Saka M 2002 J. Am. Ceram. Soc. 85 179

Wang A, Sun C, Huang R, Wen L, Cailiao Kexue and Yu Jishu 2003 J. Mater. Sci. & Technol., China, USA 19 22

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mallik, A.K., Binu, S.R., Satapathy, L.N. et al. Effect of substrate roughness on growth of diamond by hot filament CVD. Bull Mater Sci 33, 251–255 (2010). https://doi.org/10.1007/s12034-010-0039-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-010-0039-3