Abstract

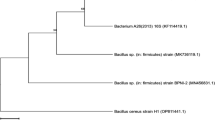

Enzymes from haloalkaliphilic microorganisms have recently focused attention on their potential and suitability in various applications. In this study, the growth and production of extracellular amylases in the marine actinomycetes, using kitchen waste as the raw starch source, have been investigated. Actinobacteria were isolated from the seawater of the Kachhighadi Coast near Dwarika, Gujarat. Seven Actinobacterial isolates of pre-monsoon, monsoon, and post-monsoon seasons belonging to different strains of Nocardiopsis genera were screened and selected for amylase production. The amylase production was initially assessed on the solid media supplemented with the extracts of different fruits and vegetable peels as a substrate by agar plate assay. The strains Kh-2(13), Kh-2(1), and Kh-3(12) produced maximum amylase with potato peel as a substrate, while no significant differences were found with the media containing other peels. Nevertheless, all strains produced amylases at a significant level with other raw substrates as well. For the optimization of the growth and enzyme production, the selected two isolates Kh-2(13) and Kh-3(12) of the monsoon and winter seasons were cultivated in a liquid medium under the submerged fermentation conditions, with potato peel as a substrate. In both organisms, the optimum amylase production was observed in the stationary phase of growth. For amylase production, the effect of different physical and chemical parameters was evaluated. The optimum growth and amylase production was achieved in 2% inoculum size, at pH 8.0, 28℃, and 5% salt concentration. On the basis of the amylase production index (API) (a ratio of the amylase units and cell growth), both isolates produced significant amylase with the only extract of potato peels, without any other supplements. The trends further indicated that while additional complex sources, such as yeast extract and peptone can enhance the cell growth of the actinobacteria, the amylase production remained unaltered. The study projects the significance of waste raw materials for the production of enzymes in extremophilic microorganisms.

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this published article.

References

Ousaadi, M. I., Merouane, F., Berkani, M., Almomani, F., Vasseghian, Y., & Kitouni, M. (2021). Valorization and optimization of agro-industrial orange waste for the production of enzyme by halophilic Streptomyces sp. Environmental Research, 201, 111494.

Al-Agamy, M. H., Alhuzani, M. R., Kelany, M. S., & Hamed, M. M. (2021). Production and partial characterization of α-amylase enzyme from marine actinomycetes. BioMed Research Internationa, 2021, 5289848

Hassan, H., & Karim, K. A. (2015). Optimization of alpha amylase production from rice straw using solid-state fermentation of Bacillus subtilis. International Journal of Environmental Science and Technology, 4(1), 1–16.

Kikani, B. A., & Singh, S. P. (2015). Enzyme stability, thermodynamics and secondary structures of α-amylase as probed by the CD spectroscopy. International Journal of Biological Macromolecules, 81, 450–460.

Zambare, V. P. (2011). Optimization of amylase production from Bacillus sp. using statistics based experimental design. Emirates Journal of Food and Agriculture. 37–47.

Elayaraja, S., Velvizhi, T., Maharani, V., Mayavu, P., Vijayalakshmi, S., & Balasubramanian, T. (2011). Thermostable α-amylase production by Bacillus firmus CAS 7 using potato peel as a substrate. African Journal of Biotechnology, 10(54), 11235–11238.

Gangadharan, D., Nampoothiri, K. M., Sivaramakrishnan, S., & Pandey, A. (2009). Biochemical characterization of raw-starch-digesting alpha amylase purified from Bacillus amyloliquefaciens. Applied Biochemistry and Biotechnology, 158(3), 653–662.

Das, K., Doley, R., & Mukherjee, A. K. (2004). Purification and biochemical characterization of a thermostable, alkaliphilic, extracellular α-amylase from Bacillus subtilis DM-03, a strain isolated from the traditional fermented food of India. Biotechnology and Applied Biochemistry, 40(3), 291–298.

Hayashida, S., Teramoto, Y., & Inoue, T. (1988). Production and characteristics of raw-potato-starch-digesting α-amylase from Bacillus subtilis 65. Applied and Environment Microbiology, 54(6), 1516–1522.

Kikani, B. A., & Singh, S. P. (2022). Amylases from thermophilic bacteria: Structure and function relationship. Critical Reviews in Biotechnology, 42(3), 325–341.

Braia, M., Cabezudo, I., Barrera, V. L., Anselmi, P., Meini, M. R., & Romanini, D. (2021). An optimization approach to the bioconversion of flour mill waste to α-amylase enzyme by Aspergillusoryzae. Process Biochemistry, 111, 102–108.

Shukla, R. J., & Singh, S. P. (2015). Characteristics and thermodynamics of α-amylase from thermophilic actinobacterium, LaceyellasacchariTSI-2. Process Biochemistry, 50(12), 2128–2136.

Abd-Elhalem, B. T., El-Sawy, M., Gamal, R. F., & Abou-Taleb, K. A. (2015). Production of amylases from Bacillus amyloliquefaciens under submerged fermentation using some agro-industrial by-products. Annals of Agricultural Science, 60(2), 193–202.

Sivaramakrishnan, S., Gangadharan, D., Nampoothiri, K. M., Soccol, C. R., & Pandey, A. (2006). α-Amylases from microbial sources–An overview on recent developments. Food Technology and Biotechnology, 44(2), 173–184.

Sharma, A. K., Kikani, B. A., & Singh, S. P. (2021). Diversity and phylogeny of actinomycetes of Arabian Sea along the Gujarat Coast. Geomicrobiology Journal, 38(4), 347–364.

Sharma, A. K., Kikani, B. A., & Singh, S. P. (2020). Biochemical, thermodynamic and structural characteristics of a biotechnologically compatible alkaline protease from a haloalkaliphilic, Nocardiopsisdassonvillei OK-18. International Journal of Biological Macromolecules, 153, 680–696.

Bhatt, H. B., & Singh, S. P. (2020). Cloning, expression, and structural elucidation of a biotechnologically potential alkaline serine protease from a newly isolated haloalkaliphilic Bacillus lehensis JO-26. Frontiers in Microbiology, 11, 941.

Bhatt, H. B., Gohel, S. D., & Singh, S. P. (2018). Phylogeny, novel bacterial lineage and enzymatic potential of haloalkaliphilic bacteria from the saline coastal desert of Little Rann of Kutch, Gujarat, India. 3 Biotech, 8(1), 1–12.

Ettoumi, B., Chouchane, H., Guesmi, A., Mahjoubi, M., Brusetti, L., Neifar, M., Borin, S., Daffonchio, D., & Cherif, A. (2016). Diversity, ecological distribution and biotechnological potential of Actinobacteria inhabiting seamounts and non-seamounts in the Tyrrhenian Sea. Microbiological Research, 186, 71–80.

Singh, S. P., Thumar, J. T., Gohel, S. D., Kikani, B., Shukla, R., Sharma, A., & Dangar, K (2013). Actinomycetes from marine habitats and their enzymatic potential. In: Marine enzymes for biocatalysis (pp. 191–214). Woodhead Publishing.

Shafiei, M., Ziaee, A. A., & Amoozegar, M. A. (2012). Purification and characterization of a halophilic α-amylase with increased activity in the presence of organic solvents from the moderately halophilic Nesterenkonia sp strain F. Extremophiles, 16(4), 627–635.

Kikani, B. A., & Singh, S. P. (2012). The stability and thermodynamic parameters of a very thermostable and calcium-independent α-amylase from a newly isolated bacterium, Ano TSSC-1. Process Biochemistry, 47(12), 1791–1798.

Yamaguchi, R., Inoue, Y., Tokunaga, H., Ishibashi, M., Arakawa, T., Sumitani, J. I., Kawaguchi, T., & Tokunaga, M. (2012). Halophilic characterization of starch-binding domain from Kocuriavarians α-amylase. International Journal of Biological Macromolecules, 50(1), 95–102.

Thumar, J. T., Dhulia, K., & Singh, S. P. (2010). Isolation and partial purification of an antimicrobial agent from halotolerant alkaliphilic Streptomyces aburaviensis strain Kut-8. World Journal of Microbiology & Biotechnology, 26(11), 2081–2087.

Mehta, V. J., Thumar, J. T., & Singh, S. P. (2006). Produ90988977ction of alkaline protease from an alkaliphilic actinomycete. Bioresource Technology, 97(14), 1650–1654.

Olakusehin, V. O., & Oyedeji, O. (2021). Production of α-amylase from Aspergillus flavus S2-OY using solid substrate fermentation of potato (Solanum tuberosum L.) peel. International Journal of Biological and Chemical Sciences, 15(5), 1950–1967.

Schieber, A., & Saldaña, M. D. (2009). Potato peels: A source of nutritionally and pharmacologically interesting compounds- review. Global Science Books, 3(2), 23–29. https://doi.org/10.7939/R33T9DM0H

Fang, W., Xue, S., Deng, P., Zhang, X., Wang, X., Xiao, Y., & Fang, Z. (2019). AmyZ1: A novel α-amylase from marine bacterium Pontibacillus sp. ZY with high activity toward raw starches. Biotechnology for Biofuels and Bioproducts, 12(1), 1–15.

Božić, N., Lončar, N., Slavić, M. Š, & Vujčić, Z. (2017). Raw starch degrading α-amylases: An unsolved riddle. Amylase, 1(1), 12–25.

Okolo, B. N., Ezeogu, L. I., & Ebisike, C. O. (1996). Raw starch digesting amylase from Thermoactinomyces thalpophius F13. World Journal of Microbiology & Biotechnology, 12(6), 637–638.

Mushtaq, Q., Irfan, M., Tabssum, F., & IqbalQazi, J. (2017). Potato peels: A potential food waste for amylase production. Journal of Food Process Engineering, 40(4), 12512.

Mukherjee, R., Paul, T., Soren, J. P., Halder, S. K., Mondal, K. C., Pati, B. R., & Das Mohapatra, P. K. (2019). Acidophilic α-amylase production from Aspergillus niger RBP7 using potato peel as substrate: A waste to value added approach. Waste and Biomass Valorization, 10(4), 851–863.

Santorelli, M., Maurelli, L., Pocsfalvi, G., Fiume, I., Squillaci, G., La Cara, F., Del Monaco, G., & Morana, A. (2016). Isolation and characterisation of a novel alpha-amylase from the extreme haloarchaeon Haloterrigena turkmenica. International Journal of Biological Macromolecules, 92, 174–184.

Abdel-Mageed, H. M., Barakat, A. Z., Bassuiny, R. I., Elsayed, A. M., Salah, H. A., Abdel-Aty, A. M., & Mohamed, S. A. (2022). Biotechnology approach using watermelon rind for optimization of α-amylase enzyme production from Trichoderma virens using response surface methodology under solid-state fermentation. Folia Microbiologica, 67(2), 253–264.

Saha, S. P., & Mazumdar, D. (2019). Optimization of process parameter for alpha-amylase produced by Bacillus cereus amy3 using one factor at a time (OFAT) and central composite rotatable (CCRD) design based response surface methodology (RSM). Biocatalysis and Agricultural Biotechnology, 19, 101168.

Gangadharan, D., Sivaramakrishnan, S., Nampoothiri, K. M., Sukumaran, R. K., & Pandey, A. (2008). Response surface methodology for the optimization of alpha amylase production by Bacillus amyloliquefaciens. Bioresource Technology, 99(11), 4597–4602.

Shukla, J., & Kar, R. (2006). Potato peel as a solid state substrate for thermostable α-amylase production by thermophilic Bacillus isolates. World Journal of Microbiology & Biotechnology, 22(5), 417–422.

Tuysuz, E., Gonul-Baltaci, N., Omeroglu, M. A., Adiguzel, A., Taskin, M., & Ozkan, H. (2020). Co-production of amylase and protease by locally isolated thermophilic bacterium Anoxybacillus rupiensis T2 in sterile and non-sterile media using waste potato peels as substrate. Waste and Biomass Valorization., 11(12), 6793–6802.

Rathore, D. S., Sheikh, M., Gohel, S., & Singh, S. P. (2019). Isolation strategies, abundance and characteristics of the marine actinomycetes of Kachhighadi, Gujarat, India. Journal of the Marine Biological Association of India, 61(1), 71–78.

Shukla, R. J., & Singh, S. P. (2015). Production optimization, purification and characterization of α-amylase from thermophilic Bacillus licheniformis TSI-14. Starke, 67(7–8), 629–639.

Chakraborty, S., Khopade, A., Biao, R., Jian, W., Liu, X. Y., Mahadik, K., Chopade, B., Zhang, L., & Kokare, C. (2011). Characterization and stability studies on surfactant, detergent and oxidant stable α-amylase from marine haloalkaliphilic Saccharopolyspora sp. A9. Journal of Molecular Catalysis B: Enzymatic, 68(1), 52–58.

Miller, G. L. (1959). Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry, 31(3), 426–428.

Rathore, D. S., Malaviya, K., Dobariya, A., & Singh, S. P. (2020). Optimization of the production of an amylase from a marine actinomycetes Nocardiopsis dassonvillei strain KaS11. In Proceedings of the National Conference on Innovations in Biological Sciences(NCIBS).

Kumar, S., & Khare, S. K. (2012). Purification and characterization of maltooligosaccharide-forming α-amylase from moderately halophilic Marinobacter sp. EMB8. Bioresource Technology, 116, 247–251.

Shafiei, M., Ziaee, A. A., & Amoozegar, M. A. (2010). Purification and biochemical characterization of a novel SDS and surfactant stable, raw starch digesting, and halophilic α-amylase from a moderately halophilic bacterium Nesterenkonia sp. strain F. Process Biochemistry, 45(5), 694–699.

Prakash, B., Vidyasagar, M., Madhukumar, M. S., Muralikrishna, G., & Sreeramulu, K. (2009). Production, purification, and characterization of two extremely halotolerant, thermostable, and alkali-stable α-amylases from Chromohalobacter sp. TVSP 101. Process Biochemistry, 44(2), 210–215.

Kokab, S., Asghar, M., Rehman, K., Asad, M. J., & Adedyo, O. (2003). Bio-processing of banana peel for α-amylase production by Bacillus subtilis. International Journal of Agriculture and Biology, 5(1), 36–39.

Rathore, D. S., Sharma, A. K., Dobariya, A., Ramavat, H., & Singh, S. P. (2022). Cultivation and diversity of marine actinomycetes: Molecular approaches and bioinformatics tools. In: Actinobacteria, (pp. 215–240). Springer.

Thumar, J., & Singh, S. P. (2022). Antimicrobial potential and metabolite profiling of marine actinobacteria. In: Actinobacteria, (pp. 241–264). Springer.

Sheikh, M., Rathore, D. S., Gohel, S., & Singh, S. P. (2019). Cultivation and characteristics of the Marine Actinobacteria from the Sea water of Alang, Bhavnagar. http://nopr.niscpr.res.in/handle/123456789/52802

Bajpai, B., Chaudhary, M., & Saxena, J. (2015). Production and characterization of α-amylase from an extremely halophilic archaeon, Haloferax sp. HA10. Food Technology and Biotechnology, 53(1), 11.

Thumar, J. T., & Singh, S. P. (2009). Organic solvent tolerance of an alkaline protease from salt-tolerant alkaliphilic Streptomyces clavuligerus strain Mit-1. Journal of Industrial Microbiology and Biotechnology, 36(2), 211.

Rathore, D. S., & Singh, S. P. (2021). Kinetics of growth and co-production of amylase and protease in novel marine actinomycete, Streptomyces lopnurensis KaM5. Folia Microbiologica, 66(3), 303–316.

Chakraborty, S., Jana, S., Gandhi, A., Sen, K. K., Zhiang, W., & Kokare, C. (2014). Gellan gum microspheres containing a novel α-amylase from marine Nocardiopsis sp. strain B2 for immobilization. International Journal of Biological Macromolecules, 70, 292–299.

Raval, V. H., Pillai, S., Rawal, C. M., & Singh, S. P. (2014). Biochemical and structural characterization of a detergent-stable serine alkaline protease from seawater haloalkaliphilic bacteria. Process Biochemistry, 49(6), 955–962.

Pandey, S., & Singh, S. P. (2012). Organic solvent tolerance of an α-amylase from haloalkaliphilic bacteria as a function of pH, temperature, and salt concentrations. Applied Biochemistry and Biotechnology, 166(7), 1747–1757.

KanthiKiran, K., & Chandra, T. S. (2008). Production of surfactant and detergent-stable, halophilic, and alkalitolerant alpha-amylase by a moderately halophilic Bacillus sp strain TSCVKK. Applied Microbiology and Biotechnology, 77(5), 1023–1031.

Thumar, J. T., & Singh, S. P. (2007). Secretion of an alkaline protease from a salt-tolerant and alkaliphilic, Streptomyces clavuligerus strain MIT-1. Brazilian Journal of Microbiology, 38, 766–772.

Kikani, B. A., & Singh, S. P. (2011). Single step purification and characterization of a thermostable and calcium independent α-amylase from Bacillus amyloliquifaciens TSWK1-1 isolated from TulsiShyam hot spring reservoir, Gujarat (India). International Journal of Biological Macromolecules, 48(4), 676–681.

Dwivedi, P., Sharma, A. K., & Singh, S. P. (2021). Biochemical properties and repression studies of an alkaline serine protease from a haloalkaliphilic actinomycete, Nocardiopsis dassonvillei subsp. albirubida OK-14. Biocatalysis and Agricultural Biotechnology, 35, 102059.

Sharma, A. K., & Singh, S. P. (2016). Effect of amino acids on the repression of alkaline protease synthesis in haloalkaliphilic Nocardiopsis dassonvillei. Biotechnology Reports, 12, 40–51.

Acknowledgements

AD and HR acknowledge the award of ShoDH Fellowships from the Government of Gujarat. The award of the UGC-BSR Faculty Fellowship to SPS is duly acknowledged. Research Funding and facilities created under the UGC-CAS, DST-FIST, DBT-Multi-Intuitional Project, MoES Net Working Project, and Saurashtra University are duly acknowledged. We wish to further state that the marine actinobacterial strains used in this study were isolated by Dr. Dalip Singh Rathore in the Laboratory of Prof. Satya P. Singh, Saurashtra University as part of the MoES Research Project. International Travel Fellowships from DST-SERB, CSIR, DBT, and UGC to SPS for presenting his work in Hamburg (Germany), Brisbane (Australia), Capetown (South Africa), and Kyoto (Japan) are also acknowledged. The authors are also grateful to M.V.M. College, Rajkot for the necessary support.

Funding

The work was primarily supported under the UGC-BSR Faculty Program (No.F.4–5(11) 2019 (BSR)). Infrastructural facilities generated under the DBT-Multi-Institutional Project (BT/PR8269/AAQ/03/307/2006), DST-FIST Program (No.SR/FST/LSI-033/2006), MoES Net Working Project (MoES/16/06/2013-RDEAS), and UGS-CAS Program (F.5–4.2012(SAP-II) of the Government of India were extensively utilized.

Author information

Authors and Affiliations

Contributions

The authors declare that they have no competing interests. Ankita Dobariya carried out the experiments and prepared the primary draft of the manuscript. Hasti Ramavat helped in the experiments and data analysis. Gira Mankad was involved in designing the experiments and preparation of the manuscript. Satya P. Singh conceived the idea, designed the experiments, and was involved in the data analysis, preparation, and editing of the manuscript.

Corresponding author

Ethics declarations

Ethics Approval and Consent to Participate

Not applicable. All authors agreed to participate in the preparation and submission of the manuscript.

Consent for Publication

All authors agree to publish the data.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Statement of Novelty

Fruit and vegetable peels are domestic waste generated in large quantities. Such waste materials are also generated in the food industries. In this study, we evaluated the usefulness of these waste materials as substrates to support microbial growth and the production of value-added products, such as enzymes. Among different waste peels evaluated, the potato peel emerged as the most potential substrate for growth and amylase production in marine actinobacteria. Various factors that affect growth and enzyme production were investigated. The selected marine actinobacterial strains effectively utilized the raw starch materials without any other supplements for growth and amylase production.

• Selected Nocardiopsis strains produced amylase using waste raw material without any other supplements.

• The extracellular α-amylases were stable in high salt and at alkaline pH.

• Additional supplements such as yeast extract and peptone marginally reduced amylase production.

Highlights

• Amylase production in haloalkaliphilic marine actinobacteria using kitchen waste.

• Fruits and vegetables peels-highly effective and sole substrates for growth and amylase production.

• Factors affecting amylase production evaluated in submerged fermentation with highly effective potato peel.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dobariya, A., Mankad, G.P., Ramavat, H. et al. Efficacy of the Fruit and Vegetable Peels as Substrates for the Growth and Production of α-Amylases in Marine Actinobacteria. Appl Biochem Biotechnol 195, 7603–7623 (2023). https://doi.org/10.1007/s12010-023-04422-z

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-023-04422-z