Abstract

The use of more appropriate kinetic models can assist in improving ethanol fermentation under conditions of very high gravity (VHG) and high cell density (HCD), in order to obtain higher amounts of ethanol in the broth combined with high productivity. The aim of this study was to model fed-batch ethanol fermentation under VHG/HCD conditions, at different temperatures, considering three types of inhibition (substrate, ethanol, and cells). Fermentations were carried out using different temperatures (28 ≤ \(T\) (°C) ≤ 34), inoculum sizes (50 ≤ \({C}_{X0}\) (g L−1) ≤ 125), and substrate concentrations in the must (258 ≤ \({C}_{SM}\) (g L−1) ≤ 436). In the proposed model, the cell inhibition power parameter varied with the temperature and inoculum size, while the cell yield coefficient varied with inoculum size and substrate concentration in the must. Hence, it was possible to propose correlations for the cell inhibition power parameter (\(m=f(T,{C}_{X0})\)) and for the cell yield coefficient (\({Y}_{X/S}=f({C}_{SM},{C}_{X0})\)), as functions of the fermentation conditions. Simulations of fed-batch ethanol fermentations at different temperatures, under VHG/HCD conditions, were performed using the proposed correlations. Experimental validation showed that the model was able to accurately predict the dynamic behavior of the fermentations in terms of the concentrations of viable cells, total cells, ethanol, and substrate.

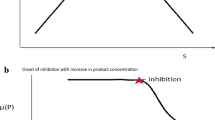

Graphical abstract

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this published article.

Abbreviations

- \({C}_{E}\) :

-

Ethanol concentration (g L−1)

- \({C}_{E0}\) :

-

Initial ethanol concentration (g L−1)

- \({C}_{Ef}\) :

-

Final ethanol concentration (g L−1)

- \({C}_{Emax}\) :

-

Maximum concentration of ethanol after which cell growth ceased (g L−1)

- \({C}_{S}\) :

-

Substrate concentration (g L−1)

- \({C}_{SM}\) :

-

Substrate concentration in the must (g L−1)

- \({C}_{S0}\) :

-

Initial substrate concentration (g L−1)

- \({C}_{Sf}\) :

-

Final substrate concentration (g L−1)

- \({C}_{VX}\) :

-

Viable cell concentration (g L−1)

- \({C}_{X}\) :

-

Total cell concentration (g L−1)

- \({C}_{X0}\) :

-

Initial total cell concentration (g L−1)

- \({C}_{Xmax}\) :

-

Maximum cell concentration after which cell growth ceased (g L−1)

- \(F\) :

-

Feed flow rate of the must (L h−1)

- \({K}_{IS}\) :

-

Substrate inhibition constant (g L−1)

- \({K}_{S}\) :

-

Saturation constant (g L−1)

- \(m\) :

-

Cell inhibition power (dimensionless)

- \(n\) :

-

Product inhibition power (dimensionless)

- \({Y}_{E/S}\) :

-

Ethanol yield coefficient (gE gS−1)

- \({Y}_{X/S}\) :

-

Cell yield coefficient (gX gS−1)

- \(\mu\) :

-

Specific cell growth rate (h−1)

- \({\mu }_{max}\) :

-

Maximum specific cell growth rate (h−1)

References

Flores-Hernández, A. A., Reyes-Reyes, J., Astorga-Zaragoza, C. M., Osorio-Gordillo, G. L., & García-Beltrán, C. D. (2018). Temperature control of an alcoholic fermentation process through the Takagi – Sugeno modeling. Chemical Engineering Research and Design, 140, 320–330. https://doi.org/10.1016/j.cherd.2018.10.021

Rivera, E. C., Yamakawa, C. K., Saad, M. B. W., Atala, D. I. P., Ambrosio, W. B., Bonomi, A., Nolasco, J., & Rossell, C. E. V. (2017). Effect of temperature on sugarcane ethanol fermentation: Kinetic modeling and validation under very-high-gravity fermentation conditions. Biochemical Engineering Journal, 119, 42–51. https://doi.org/10.1016/j.bej.2016.12.002

Rodrigues, K. C. S., Sonego, J. L. S., Cruz, A. J. G., Bernardo, A., & Badino, A. C. (2018). Modeling and simulation of continuous extractive fermentation with CO2stripping for bioethanol production. Chemical Engineering Research and Design, 132, 77–88. https://doi.org/10.1016/j.cherd.2017.12.024

Camargos, C. V., Moraes, V. D., Oliveira, L. M., Guidini, C. Z., Ribeiro, E. J., & Santos, L. D. (2020). High gravity and very high gravity fermentation of sugarcane molasses by flocculating saccharomyces cerevisiae : Experimental investigation and kinetic modeling. Applied Biochemistry and Biotechnology, 193, 807–821.

Monod, J. (1949). The growth of bacterial cultures. Annual Review of Microbiology., 3, 371–394.

Andrews, J. F. (1968). A mathematical model for the continuous culture of microorganisms utilizing inhibitory substrates. Biotechnology and Bioengineering, 10(6), 707–723. https://doi.org/10.1002/bit.260100602

Levenspiel, O. (1980). The monod equation: A revisit and a generalization to product inhibition situations. Biotechnology and Bioengineering, 22(8), 1671–1687. https://doi.org/10.1002/bit.260220810

Lee, J. M., Pollard, J. F., & Coulman, G. A. (1983). Ethanol fermentation with cell recycling: Computer simulation. Biotechnology and Bioengineering, 25, 497–511. https://doi.org/10.1002/bit.260250215

Aiba, S., Shoda, M., & Nagatani, M. (1968). Kinetics of product inhibition in alcohol fermentation. Biotechnology and Bioengineering, 10, 845–864.

Monbouquette, H. G. (1992). Modeling high-biomass-density cell recycle ferment ors. Biotechnology and Bioengineering, 39, 498–503.

Veloso, I. I. K., Rodrigues, K. C. S., Sonego, J. L. S., Cruz, A. J. G., & Badino, A. C. (2019). Fed-batch ethanol fermentation at low temperature as a way to obtain highly concentrated alcoholic wines: Modeling and optimization. Biochemical Engineering Journal, 141, 60–70. https://doi.org/10.1016/j.bej.2018.10.005

Dias, M. O. S., Maciel Filho, R., Mantelatto, P. E., Cavalett, O., Rossell, C. E. V., Bonomi, A., & Leal, M. R. L. V. (2015). Sugarcane processing for ethanol and sugar in Brazil. Environmental Development, 15, 35–51. https://doi.org/10.1016/j.envdev.2015.03.004

Pereira, R. D., Rodrigues, K. C. S., Sonego, J. L. S., Cruz, A. J. G., & Badino, A. C. (2018). A new methodology to calculate the ethanol fermentation efficiency at bench and industrial scales. Industrial and Engineering Chemistry Research, 57(48), 16182–16191. https://doi.org/10.1021/acs.iecr.8b03943

Wheals, A. E., Basso, L. C., Alves, D. M., & Amorim, H. V. (1999). Fuel ethanol after 25 years. Trends Biotechnol, 17(12), 482–487.

Puligundla, P., Smogrovicova, D., Obulam, V. S. R., & Ko, S. (2011). Very high gravity ( VHG ) ethanolic brewing and fermentation : A research update. Journal of industrial microbiology & biotechnology, 38, 1133–1144. https://doi.org/10.1007/s10295-011-0999-3

Yamakawa, C. K., Rivera, E. C., Kwon, H., Agudelo, W. E. H., Saad, M. B. W., Leal, J., Rossel, C. E. V., Bonomi, A., & Maciel, R. (2019). Study of in fl uence of yeast cells treatment on sugarcane ethanol fermentation : Operating conditions and kinetics. Biochemical Engineering Journal, 147(August 2018), 1–10. https://doi.org/10.1016/j.bej.2019.03.022

Cruz, M. L., Resende, M. M., & Ribeiro, E. J. (2018). Evaluation of process conditions in the performance of yeast on alcoholic fermentation. Chemical Engineering Communications, 205(6), 846–855. https://doi.org/10.1080/00986445.2017.1423061

Cruz, M. L., Resende, M. M., & Ribeiro, E. J. (2021). Improvement of ethanol production in fed - batch fermentation using a mixture of sugarcane juice and molasse under very high - gravity conditions. Bioprocess and Biosystems Engineering, 44(3), 617–625. https://doi.org/10.1007/s00449-020-02462-x

Vega, J. L., Navarro, A. R., Clausen, E. C., & Gaddy, J. L. (1986). Effects of lnoculum size on ethanol inhibition modeling and other fermentation parameters. Biotechnology and Bioengineering, 29, 633–638.

Atala, D. I. P., Costa, A. C., Maciel, R., & Maugeri, F. (2001). Kinetics of ethanol fermentation with high biomass concentration considering the effect of temperature. Applied Biochemistry and Biotechnology - Part A Enzyme Engineering and Biotechnology, 91–93, 353–365. https://doi.org/10.1385/ABAB:91-93:1-9:353

Cheng, J., Ding, M., Tian, H., & Yuan, Y. (2009). Inoculation-density-dependent responses and pathway shifts in Saccharomyces cerevisiae. Proteomics, 9, 4704–4713. https://doi.org/10.1002/pmic.200900249

Westman, J. O., & Franzén, C. J. (2015). Current progress in high cell density yeast bioprocesses for bioethanol production. Biotechnology Journal, 10, 1185–1195. https://doi.org/10.1002/biot.201400581

Lafforgue, C., Malinowski, J., & Goma, G. (1987). High yeast concentration in continuous fermentation with cell recycle obtained by tangential microfiltration. Biotechnology Letters, 9(5), 347–352.

Maiorella, B., Blanch, H. W., & Wilke, C. R. (1983). By-product inhibition effects on ethanolic fermentation by Saccharomyces cerevisiae. Biotechnology and Bioengineering, 25(1), 103–121. https://doi.org/10.1002/bit.260250109

Lee, C. W., & Chang, H. N. (1987). Kinetics of ethanol fermentations in membrane cell recycle fermentors. Biotechnology & Bioengineering, 29, 1105–1112.

Cysewski, G. R., & Wilke, C. R. (1977). Rapid ethanol fermentations using vacuum and cell recycle. Biotechnology & Bioengineering, 19, 1125–1143.

Laluce, C., Tognolli, J. O., Oliveira, K. F., Souza, C. S., & Morais, M. R. (2009). Optimization of temperature, sugar concentration, and inoculum size to maximize ethanol production without significant decrease in yeast cell viability. Applied Microbiology and Biotechnology, 83, 627–637. https://doi.org/10.1007/s00253-009-1885-z

Sonego, J. L. S., Lemos, D. A., Pinto, C. E. M., Cruz, A. J. G., & Badino, A. C. (2016). Extractive fed-batch ethanol fermentation with CO2 stripping in a bubble column bioreactor: Experiment and modeling. Energy and Fuels, 30(1), 748–757. https://doi.org/10.1021/acs.energyfuels.5b02320

Lemos, D. A., Sonego, J. L. S., Cruz, A. J. G., & Badino, A. C. (2020). Improvement of ethanol production by extractive fed - batch fermentation in a drop column bioreactor. Bioprocess and Biosystems Engineering, 43(12), 2295–2303. https://doi.org/10.1007/s00449-020-02414-5

Guidini, C. Z., Diniz, L. M. S., Silva, H. A., Resende, M. M., Cardoso, L. V., & Ribeiro, E. J. (2014). Alcoholic fermentation with flocculant saccharomyces cerevisiae in fed-batch process. Applied Biochemistry and Biotechnology, 172, 1623–1638. https://doi.org/10.1007/s12010-013-0646-8

Basso, L. C., Basso, T. O., & Rocha, S. N. (2011). Ethanol production in Brazil: The industrial process and its impact on yeast fermentation. In Biofuel Production-Recent Developments and Prospects. InTech. https://doi.org/10.5772/17047

Sonego, J. L. S., Lemos, D. A., Cruz, A. J. G., & Badino, A. C. (2018). Optimization of fed-batch fermentation with in situ ethanol removal by CO2stripping. Energy and Fuels, 32(1), 954–960. https://doi.org/10.1021/acs.energyfuels.7b02979

Lee, S. S., Robinson, F. M., & Wang, H. Y. (1981). Rapid determination of yeast viability. Biotechnology and Bioengineering Symposium, 11, 641–649.

Novaes, L. R., Resende, N. S., & Salim, V. M. M. (2017). Modeling, simulation and kinetic parameter estimation for diesel hydrotreating. Fuel, 209(July), 184–193. https://doi.org/10.1016/j.fuel.2017.07.092

Ospino-pinedo, J., Sánchez, M. E., & Matallana-pérez, L. G. (2018). Modeling and control of processes using the EMSO simulator and SIMATIC PLC as OPC inter-face. Revista Facultad de Ingeniería, 87, 58–69. https://doi.org/10.17533/udea.redin.n87a08

Cysewski, G. R., & Wilke, C. R. (1978). Process design and economic studies of alternative fermentation methods for the production of ethanol. Biotechnology & Bioengineering, 20, 1421–1444.

Jarzebski, A. B., Malinowski, J. J., & Goma, G. (1989). Modeling of ethanol fermentation at high yeast concentrations. Biotechnology and Bioengineering, 34, 1225–1230.

Avbelj, M., Zupan, J., Kranjc, L., & Raspor, P. (2015). Quorum-sensing kinetics in Saccharomyces cerevisiae : A symphony of ARO genes and aromatic alcohols. Journal of Agricultural and Food Chemistry, 63(38), 8544–8550. https://doi.org/10.1021/acs.jafc.5b03400

Amillastre, E., Aceves-Lara, C., Uribelarrea, J., Alfenore, S., & Guillouet, S. E. (2012). Dynamic model of temperature impact on cell viability and major product formation during fed-batch and continuous ethanolic fermentation in Saccharomyces cerevisiae. Bioresource Technology, 117, 242–250. https://doi.org/10.1016/j.biortech.2012.04.013

Phisalaphong, M., Srirattana, N., & Tanthapanichakoon, W. (2006). Mathematical modeling to investigate temperature effect on kinetic parameters of ethanol fermentation. Biochemical Engineering Journal, 28(1), 36–43. https://doi.org/10.1016/j.bej.2005.08.039

Pereira, F. B., Gomes, D. G., Guimarães, P. M. R., Teixeira, J. A., & Domingues, L. (2012). Cell recycling during repeated very high gravity bio-ethanol fermentations using the industrial Saccharomyces cerevisiae. Biotechnology Letters, 34, 45–53. https://doi.org/10.1007/s10529-011-0735-0

Acknowledgements

The authors are grateful for the financial supports received in this research.

Funding

This study was financed in part by Coordenação de Aperfeiçoamento de Pessoal de Nível Superior- Brazil (CAPES, Finance Code 001). This study was also financially supported by the Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP, grant number 2018/11405–5) and the Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq, grant numbers 431460/2016–7, 310098/2017–3, 141300/2019–1, and 140761/2017–9).

Author information

Authors and Affiliations

Contributions

Ivan I. K. Veloso: conceptualization, methodology, validation, investigation, data curation, and writing — original draft. Kaio C. S. Rodrigues: conceptualization, methodology, validation, investigation, data curation, and writing — review & editing. Gustavo Batista: software, writing — review & editing. Antonio J. G. Cruz: supervision and writing — review & editing. Alberto C. Badino: supervision and writing — review & editing, resources, and funding acquisition.

Corresponding author

Ethics declarations

Ethics Approval

This article does not contain any studies with human participants performed or animals by any of the authors.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Veloso, I.I.K., Rodrigues, K.C.S., Batista, G. et al. Mathematical Modeling of Fed-Batch Ethanol Fermentation Under Very High Gravity and High Cell Density at Different Temperatures. Appl Biochem Biotechnol 194, 2632–2649 (2022). https://doi.org/10.1007/s12010-022-03868-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-022-03868-x