Abstract

Sweet sorghum bagasse (SSB) is an under-utilized feedstock for biochemical conversion to biofuels or high value chemicals. One such chemical that can be generated biochemically and applied to a wide array of industries from pharmaceuticals to the production of liquid transportation fuels is butyric acid. This work investigated cultivating the butyric acid producing strain Clostridium tyrobutyricum ATCC 25755 on low-moisture anhydrous ammonia (LMAA) pretreated SSB. Pretreated SSB hydrolysate was detoxified and supplemented with urea for shake flask batch fermentation to show that up to 11.4 g/L butyric acid could be produced with a selectivity of 87% compared to other organic acids. Bioreactor fermentation with pH control showed high biomass growth, but a similar output of 11.3 g/L butyric acid was achieved. However, the butyric acid productivity increased to 0.251 g/L∙hr with a butyric acid yield of 0.29 g/g sugar consumed. This butyric acid output represented an 83% theoretical yield. Further improvements in butyric acid titer and yield can be achieved by optimizing nutrient supplementation and incorporating fed-batch fermentation processing of pretreated SSB hydrolysate.

Construction of ZGO:Sr NR- and ZGC@PDA NP-driven ratiometric aptasensor for CEA detection.

Similar content being viewed by others

References

Rausch, K.D., Hummel, D., Johnston, L.A., & May, J.B. (2019). In Corn: Chemistry and technology, third edition. In S. O. Serna-Saldivar (Ed.) (pp. 501–535). AACC International Press.

Fulton, L. M., Lynd, L. R., Körner, A., Greene, N., & Tonachel, L. R. (2015). The need for biofuels as part of a low carbon energy future. Biofuels, Bioproducts and Biorefining, 9(5), 476–483.

Dale, B. E., Anderson, J. E., Brown, R. C., Csonka, S., Dale, V. H., Herwick, G., Jackson, R. D., Jordan, N., Kaffka, S., Kline, K. L., Lynd, L. R., Malmstrom, C., Ong, R. G., Richard, T. L., Taylor, C., & Wang, M. Q. (2014). Take a closer look: Biofuels can support environmental, economic and social goals. Environmental Science & Technology, 48(13), 7200–7203.

Jesus, E. D. C., Liang, C., Quensen, J. F., Susilawati, E., Jackson, R. D., Balser, T. C., & Tiedje, J. M. (2016). Influence of corn, switchgrass, and prairie cropping systems on soil microbial communities in the upper Midwest of the United States. GCB Bioenergy, 8, 481–494.

Dai, J., Bean, B., Brown, B., Bruening, W., Edwards, J., Flowers, M., Karow, R., Lee, C., Morgan, G., Ottman, M., Ransom, J., & Wiersma, J. (2016). Harvest index and straw yield of five classes of wheat. Biomass and Bioenergy, 85, 223–227.

Nghiem, N. P., Montanti, J., & Johnston, D. B. (2016). Sorghum as a renewable feedstock for production of fuels and industrial chemicals. AIMS Bioengineering, 3(1), 75–91.

Shukla, S., Felderhoff, T. J., Saballos, A., & Vermerris, W. (2017). The relationship between plant height and sugar accumulation in the stems of sweet sorghum (Sorghum bicolor (L.) Moench). Field Crops Research, 203, 181–191.

Laopaiboon, L., Nuanpeng, S., Srinophakun, P., Klanrit, P., & Laopaiboon, P. (2009). Ethanol production from sweet sorghum juice using very high gravity technology: Effects of carbon and nitrogen supplementations. Bioresource Technology, 100(18), 4176–4182.

Liang, Y. N., Sarkany, N., Cui, Y., Yesuf, J., Trushenski, J., & Blackburn, J. W. (2010). Use of sweet sorghum juice for lipid production by Schizochytrium limacinum SR21. Bioresource Technology, 101(10), 3623–3627.

Hetényi, K., Gál, K., Németh, Á., & Sevella, B. (2010). Use of sweet sorghum juice for lactic acid fermentation: Preliminary steps in a process optimization. Journal of Chemical Technology & Biotechnology, 85(6), 872–877.

Eggleston, G., DeLucca, A., Sklanka, S., Dalley, C., Cyr, E. S., & Powell, R. (2015). Investigation of the stabilization and preservation of sweet sorghum juices. Industrial Crops and Products, 64, 258–270.

Bennett, A. S., & Anex, R. P. (2009). Production, transportation and milling costs of sweet sorghum as a feedstock for centralized bioethanol production in the upper Midwest. Bioresource Technology, 100(4), 1595–1607.

Li, B.-Z., Balan, V., Yuan, Y.-J., & Dale, B. E. (2010). Process optimization to convert forage and sweet sorghum bagasse to ethanol based on ammonia fiber expansion (AFEX) pretreatment. Bioresource Technology, 101(4), 1285–1292.

van Rijn, R., Nieves, I. U., Shanmugam, K. T., Ingram, L. O., & Vermerris, W. (2018). Techno-economic evaluation of cellulosic ethanol production based on pilot biorefinery data: A case study of sweet sorghum bagasse processed via L+SScF. Bioenergy Research, 11(2), 414–425.

Qureshi, N., Saha, B. C., Klasson, K. T., & Liu, S. (2018). Butanol production from sweet sorghum bagasse with high solids content: Part I—Comparison of liquid hot water pretreatment with dilute sulfuric acid. Biotechnology Progress, 34(4), 960–966.

Gupta, R., & Lee, Y. (2010). Pretreatment of corn stover and hybrid poplar by sodium hydroxide and hydrogen peroxide. Biotechnology Progress, 26(4), 1180–1186.

Yu, M., Li, J., Chang, S., Zhang, L., Mao, Y., Cui, T., Yan, Z., Luo, C., & Li, S. (2016). Bioethanol production using the sodium hydroxide pretreated sweet sorghum bagasse without washing. Fuel, 175, 20–25.

Yoo, C. G., Nghiem, N. P., Hicks, K. B., & Kim, T. H. (2011). Pretreatment of corn stover using low-moisture anhydrous ammonia (LMAA) process. Bioresource Technology, 102(21), 10028–10034.

Yang, M., & Rosentrater, K. A. (2017). Small-scale low-moisture anhydrous ammonia (LMAA) pretreatment of corn stover. Biomass and Bioenergy, 97, 38–42.

Alonso, D. M., Hakim, S. H., Zhou, S., Won, W., Hosseinaei, O., Tao, J., Garcia-Negron, V., Motagamwala, A. H., Mellmer, M. A., & Huang, K. (2017). Increasing the revenue from lignocellulosic biomass: Maximizing feedstock utilization. Science Advances, 3(5), e1603301.

McAloon, A., Taylor, F., Yee, W., Ibsen, K., & Wooley, R. (2000). Determining the cost of producing ethanol from corn starch and lignocellulosic feedstocks. Golden, CO (US): National Renewable Energy Lab.

Liang, Y., Tang, T., Umagiliyage, A. L., Siddaramu, T., McCarroll, M., & Choudhary, R. (2012). Utilization of sorghum bagasse hydrolysates for producing microbial lipids. Applied Energy, 91(1), 451–458.

Matsakas, L., Sterioti, A.-A., Rova, U., & Christakopoulos, P. (2014). Use of dried sweet sorghum for the efficient production of lipids by the yeast Lipomyces starkeyi CBS 1807. Industrial Crops and Products, 62, 367–372.

Ryu, B.-G., Kim, J., Kim, K., Choi, Y.-E., Han, J.-I., & Yang, J.-W. (2013). High-cell-density cultivation of oleaginous yeast Cryptococcus curvatus for biodiesel production using organic waste from the brewery industry. Bioresource Technology, 135, 357–364.

Stoklosa, R. J., Johnston, D. B., & Nghiem, N. P. (2019). Phaffia rhodozyma cultivation on structural and non-structural sugars from sweet sorghum for astaxanthin generation. Process Biochemistry, 83, 9–17.

Cai, D., Zhang, T., Zheng, J., Chang, Z., Wang, Z., & Qin, P.-y. and Tan, T.-w. (2013). Biobutanol from sweet sorghum bagasse hydrolysate by a hybrid pervaporation process. Bioresource Technology, 145, 97–102.

Jiang, L., Fu, H., Yang, H. K., Xu, W., Wang, J., & Yang, S.-T. (2018). Butyric acid: Applications and recent advances in its bioproduction. Biotechnology Advances, 36(8), 2101–2117.

Baroi, G. N., Gavala, H. N., Westermann, P., & Skiadas, I. V. (2017). Fermentative production of butyric acid from wheat straw: Economic evaluation. Industrial Crops and Products, 104, 68–80.

Yang, S.-T., El-Ensashy, H., & Thongchul, N. (Eds.) (2013). Bioprocessing Technologies in Biorefinery for Sustainable Production of Fuels, Chemicals, and Polymers. John Wiley & Sons.

Baroi, G., Baumann, I., Westermann, P., & Gavala, H. N. (2015). Butyric acid fermentation from pretreated and hydrolysed wheat straw by an adapted C. lostridium tyrobutyricum strain. Microbial Biotechnology, 8(5), 874–882.

Liu, S., Bischoff, K. M., Leathers, T. D., Qureshi, N., Rich, J. O., & Hughes, S. R. (2013). Butyric acid from anaerobic fermentation of lignocellulosic biomass hydrolysates by Clostridium tyrobutyricum strain RPT-4213. Bioresource Technology, 143, 322–329.

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D., & Crocker, D. (2008). Determination of structural carbohydrates and lignin in biomass. Laboratory analytical procedure, 1617(1), 1–16.

Stoklosa, R. J., Nghiem, N. P., & Latona, R. J. (2019). Xylose-enriched ethanol fermentation stillage from sweet sorghum for xylitol and astaxanthin production. Fermentation, 5(4), 84.

Koo, B., Park, J., Gonzalez, R., Jameel, H., & Park, S. (2019). Two-stage autohydrolysis and mechanical treatment to maximize sugar recovery from sweet sorghum bagasse. Bioresource Technology, 276, 140–145.

Kim, J. S., Lee, Y. Y., & Kim, T. H. (2016). A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresource Technology, 199, 42–48.

Nghiem, N. P., Senske, G. E., & Kim, T. H. (2016). Pretreatment of corn stover by low moisture anhydrous ammonia (LMAA) in a pilot-scale reactor and bioconversion to fuel ethanol and industrial chemicals. Applied Biochemistry and Biotechnology, 179(1), 111–125.

Gibson, T. (1965). Clostridia in silage. Journal of Applied Bacteriology, 28, 56–62.

Dwidar, M., Kim, S., Jeon, B. S., Um, Y., Mitchell, R. J., & Sang, B.-I. (2013). Co-culturing a novel Bacillus strain with Clostridium tyrobutyricum ATCC 25755 to produce butyric acid from sucrose. Biotechnology for Biofuels, 6(1), 35.

Baroi, G. N., Skiadas, I. V., Westermann, P., & Gavala, H. N. (2015). Continuous fermentation of wheat straw hydrolysate by Clostridium tyrobutyricum with in-situ acids removal. Waste and Biomass Valorization, 6(3), 317–326.

Michel-Savin, D., Marchal, R., & Vandecasteele, J. (1990). Butyrate production in continuous culture of Clostridium tyrobutyricum: Effect of end-product inhibition. Applied Microbiology and Biotechnology, 33, 127–131.

Wu, Z., & Yang, S. T. (2003). Extractive fermentation for butyric acid production from glucose by Clostridium tyrobutyricum. Biotechnology and Bioengineering, 82(1), 93–102.

Zhang, C., Yang, H., Yang, F., & Ma, Y. (2009). Current progress on butyric acid production by fermentation. Current Microbiology, 59(6), 656–663.

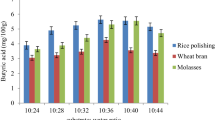

Sjöblom, M., Matsakas, L., Christakopoulos, P., & Rova, U. (2015). Production of butyric acid by Clostridium tyrobutyricum (ATCC25755) using sweet sorghum stalks and beet molasses. Industrial Crops and Products, 74, 535–544.

Wang, L., Ou, M. S., Nieves, I., Erickson, J. E., Vermerris, W., Ingram, L., & Shanmugam, K. (2015). Fermentation of sweet sorghum derived sugars to butyric acid at high titer and productivity by a moderate thermophile Clostridium thermobutyricum at 50° C. Bioresource Technology, 198, 533–539.

Lau, M. W., Dale, B. E., & Balan, V. (2008). Ethanolic fermentation of hydrolysates from ammonia fiber expansion (AFEX) treated corn stover and distillers grain without detoxification and external nutrient supplementation. Biotechnology and Bioengineering, 99(3), 529–539.

Lau, M. W., Gunawan, C., & Dale, B. E. (2009). The impacts of pretreatment on the fermentability of pretreated lignocellulosic biomass: A comparative evaluation between ammonia fiber expansion and dilute acid pretreatment. Biotechnology for Biofuels, 2(1), 30.

Acknowledgments

The authors would like to thank Delta Biorenewables for the supply of sweet sorghum bagasse, Novozymes for providing enzymes, and Matt Toht for performing biomass pretreatment.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflicts of interest.

Human and Animal Rights and Informed Consent

The research performed did not involve any human or animal subjects. The research did not require informed consent.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Mention of trade names or commercial products in this publication is solely for providing specific information and does not imply recommendation or endorsement by the US Department of Agriculture. USDA is an equal opportunity provider and employer.

Rights and permissions

About this article

Cite this article

Stoklosa, R.J., Moore, C., Latona, R.J. et al. Butyric Acid Generation by Clostridium tyrobutyricum from Low-Moisture Anhydrous Ammonia (LMAA) Pretreated Sweet Sorghum Bagasse. Appl Biochem Biotechnol 193, 761–776 (2021). https://doi.org/10.1007/s12010-020-03449-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-020-03449-w