Abstract

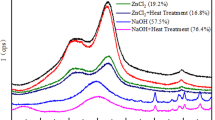

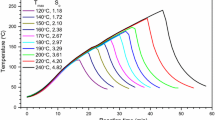

The effects of liquid hot water combined with 1, 4-butanediol (LHW-BDO) on the chemical composition and structure of moso bamboo were investigated. The structure changes of moso bamboo fibers were characterized by infrared spectroscopy, X-ray diffraction, and electronic scanning electron microscopy. The results showed that the delignification rates of 1, 4-butanediol (BDO) and LHW-BDO pretreatment methods were at the same level (91.42–93.08%). However, compared with BDO pretreatment, the cellulose content in solid residue after LHW-BDO pretreatment was increased by 17.06% with a recovery rate of 75.68%, while the hemicellulose removal rate increased by 115.33% and reached 50.34%. After LHW-BDO pretreatment, the intramolecular hydrogen bonds, intermolecular hydrogen bonds, methylene bonds, and aromatic ether bonds of the fibers were broken, which contributed to the depolymerization and separation of cellulose, hemicellulose, and lignin molecules. However, LHW-BDO pretreatment does not destroy the β-glycoside bond which links the glucose molecule inside the fiber molecule, which was also beneficial to the separation of cellulose. In addition, the amorphous zone of bamboo fibers was destroyed by the above treatments, and the fiber structure of bamboo samples mostly exists in crystalline form. The crystallinity of bamboo pretreated with LHW-BDO was increased by 32.15%. It can be found by scanning electron microscopy that the surface of the pretreated bamboo samples showed uniformly distributed bubbly protuberance.

Similar content being viewed by others

References

Mohan, M., Banerjee, T., & Goud, V. V. (2015). Hydrolysis of bamboo biomass by subcritical water treatment. Bioresource Technology, 191, 244–252.

Muhammad, N., Man, Z., Bustam, M. A., Mutalib, M. I. A., & Rafiq, S. (2013). Investigations of novel nitrile-based ionic liquids as pre-treatment solvent for extraction of lignin from bamboo biomass. Journal of Industrial and Engineering Chemistry, 19(1), 207–214.

Lin, Y. T., Tang, S. L., Pai, C. W., Whitman, W. B., Coleman, D. C., & Chiu, C. Y. (2014). Changes in the soil bacterial communities in a cedar plantation invaded by moso bamboo. Microbial Ecology, 67(2), 421–429.

Mao, F., Zhou, G., Li, P., Du, H., Xu, X., Shi, Y., Mo, L., Zhou, Y., & Tu, G. (2017). Optimizing selective cutting strategies for maximum carbon stocks and yield of moso bamboo forest using BIOME-BGC model. Journal of Environmental Management, 191, 126–135.

Teodoro, R., Raabe, J., Wisky Silva, D., Farinassi Mendes, R., Mendes, L. M., & Tonoli, G. H. D. (2015). Functionally graded mdp panels using bamboo particles. Key Engineering Materials, 668, 9.

Ma, W. S. A., Wang, M. J. J., & Chou, F. S. (1991). Evaluating the mechanical injury problem in the wood-bamboo furniture manufacturing industry. International Journal of Industrial Ergonomics, 7(4), 347–355.

Liu, D., Song, J., Anderson, D. P., Chang, P. R., & Hua, Y. (2012). Bamboo fiber and its reinforced composites: structure and properties. Cellulose, 19(5), 1449–1480.

Chen, G., Chen, K., Zhang, R., Chen, X., Hu, P., & Kan, J. (2018). Polysaccharides from bamboo shoots processing by-products: new insight into extraction and characterization. Food Chemistry, 245, 1113.

Liao, P., Zhan, Z., Dai, J., Wu, X., Zhang, W., Wang, K., et al. (2013). Adsorption of tetracycline and chloramphenicol in aqueous solutions by bamboo charcoal: a batch and fixed-bed column study. Chemical Engineering Journal, 228, 496–505.

Huo, Y., Liu, Z., Xuan, H., Lu, C., Yu, L., Bao, W., & Zhao, G. (2016). Effects of bamboo vinegar powder on growth performance and mRNA expression levels of interleukin-10, interleukin-22, and interleukin-25 in immune organs of weaned piglets. Animal Nutrition, 2(2), 111–118.

He, J., Zhang, M., Cui, S., & Wang, S.-Y. (2009). High-quality cellulose triacetate prepared from bamboo dissolving pulp. Journal of Applied Polymer Science, 113(1), 456–465.

Isikgor, F. H., & Becer, C. R. (2015). Lignocellulosic biomass: a sustainable platform for the production of bio-based chemicals and polymers. Polymer Chemistry, 6(25), 4497–4559.

Kassaye, S., Pant, K. K., & Jain, S. (2017). Hydrolysis of cellulosic bamboo biomass into reducing sugars via a combined alkaline solution and ionic liquid pretreament steps. Renewable Energy, 104(Complete), 177–184.

Wojtusik, M., Villar, J. C., Zurita, M., Ladero, M., & Garcia-Ochoa, F. (2017). Study of the enzymatic activity inhibition on the saccharification of acid pretreated corn stover. Biomass and Bioenergy, 98, 1–7.

Kapoor, M., Raj, T., Vijayaraj, M., Chopra, A., Gupta, R. P., Tuli, D. K., & Kumar, R. (2015). Structural features of dilute acid, steam exploded, and alkali pretreated mustard stalk and their impact on enzymatic hydrolysis. Carbohydrate Polymers, 124, 265–273.

Guan, W., Shi, S., & Blersch, D. (2018). Effects of tween 80 on fermentative butanol production from alkali-pretreated switchgrass. Biochemical Engineering Journal, 135, 61–70.

Zhang, K., Pei, Z., & Wang, D. (2016). Organic solvent pretreatment of lignocellulosic biomass for biofuels and biochemicals: a review. Bioresource Technology, 199, 21–33.

Sabanci, K., & Buyukkileci, A. O. (2018). Comparison of liquid hot water, very dilute acid and alkali treatments for enhancing enzymatic digestibility of hazelnut tree pruning residues. Bioresource Technology, 261, 158–165.

Sluiter, J. B., Ruiz, R. O., Scarlata, C. J., Sluiter, A. D., & Templeton, D. W. (2010). Compositional analysis of lignocellulosic feedstocks. 1. Review and description of methods. Journal of Agricultural and Food Chemistry, 58(16), 9043–9053.

Chandel, A. K., Antunes, F. A., Anjos, V., Bell, M. J., Rodrigues, L. N., Polikarpov, I., Azevedo, E., Bernardinelli, O., Rosa, C., Pagnocca, F., & Silva, S. (2014). Multi-scale structural and chemical analysis of sugarcane bagasse in the process of sequential acid–base pretreatment and ethanol production by scheffersomyces shehataeandsaccharomyces cerevisiae. Biotechnology for Biofuels, 7(1), 63.

Segal, L., Creely, J. J., Martin, A. E., & Conrad, C. M. (1959). An empirical method for estimating the degree of crystallinity of native cellulose using the x-ray diffractometer. Textile Research Journal, 29(10), 786–794.

Kim, T. H., & Lee, Y. Y. (2005). Pretreatment and fractionation of corn stover by ammonia recycle percolation process. Bioresource Technology, 96(18), 2007–2013.

Li, C., Knierim, B., Manisseri, C., Arora, R., Scheller, H. V., Auer, M., Vogel, K. P., Simmons, B. A., & Singh, S. (2010). Comparison of dilute acid and ionic liquid pretreatment of switchgrass: biomass recalcitrance, delignification and enzymatic saccharification. Bioresource Technology, 101(13), 4900–4906.

Funding

This work is supported financially by Key Lab. of Biomass Energy and Material, Jiangsu Province (JSBEM-S-2017011) and National Natural Science Foundation of China (Grant No. 31770636).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Human Rights and Informed Consent

This article does not contain any studies with human participants or animals performed by any of the authors. Informed consent was obtained from all individual participants included in the study.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, N., Xu, H., Yang, J. et al. Effects of Liquid Hot Water Combined with 1, 4-Butanediol on Chemical Composition and Structure of Moso Bamboo. Appl Biochem Biotechnol 190, 1177–1186 (2020). https://doi.org/10.1007/s12010-019-03173-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-019-03173-0