Abstract

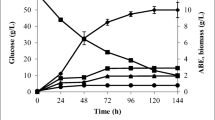

The foremost aim of the present study was to enhance butanol production in an extractive fermentation study in presence of non-ionic surfactant using immobilized cells. Earlier studies had shown improved butanol production with non-ionic surfactant and immobilized cells independently. Therefore, in the present work, the combined effect of extractive fermentation and immobilized cells on butanol production was studied. Different matrices (brick, bamboo, cotton fiber, flannel cloth, and polyurethane foam) were tested for immobilization of Clostridium sporogenes. Immobilized biomass thus obtained was used in an extractive fermentation study with non-ionic surfactant L62. Biomass immobilized on polyurethane foam (PF) doubled the butanol production in presence of 6% (v/v) L62 with respect to control (free cells without surfactant). Further, the effect of different carbon sources was also studied to check the suitability of different industrial wastes containing different carbon sources. Glucose was found to be the best carbon source.

Similar content being viewed by others

References

Antoni, D., Zverlov, V. V., & Schwarz, W. H. (2007). Biofuels from microbes. Applied Microbiology and Biotechnology,77(1), 23–35.

Friedl, A. (2012). Lignocellulosic biorefinery. Environmental Engineering & Management Journal (EEMJ), 11.

Qureshi, N., & Blaschek, H. (2001). Evaluation of recent advances in butanol fermentation, upstream, and downstream processing. Bioprocess and Biosystems Engineering,24(4), 219–226.

Kujawska, A., Kujawski, J., Bryjak, M., & Kujawski, W. (2015). ABE fermentation products recovery methods—a review. Renewable and Sustainable Energy Reviews,48, 648–661.

Durre, P. (2007). Biobutanol: an attractive biofuel. Biotechnology Journal,2(12), 1525–1534.

Jones, D. T., & Woods, D. R. (1986). Acetone-butanol fermentation revisited. Microbiological Reviews,50, 484.

Datta, R., Zeikus, J.G. (1985). Production of butanol by fermentation in the presence of carbon monoxide, Google Patents

Flickinger, M.C., Drew, S.W. (1999). Encyclopedia of bioprocess technology. ed John Wiley.

Sarchami, T., Munch, G., Johnson, E., Kießlich, S., & Rehmann, L. (2016). A review of process-design challenges for industrial fermentation of butanol from crude glycerol by non-biphasic Clostridium pasteurianum. Fermentation,2(4), 13.

Quispe, C. A., Coronado, C. J., & Carvalho, J. A., Jr. (2013). Glycerol: production, consumption, prices, characterization and new trends in combustion. Renewable and Sustainable Energy Reviews,27, 475–493.

Hansen, C., Hernandez, A., Mullan, B., Moore, K., Trezona-Murray, M., King, R., & Pluske, J. (2009). A chemical analysis of samples of crude glycerol from the production of biodiesel in Australia, and the effects of feeding crude glycerol to growing-finishing pigs on performance, plasma metabolites and meat quality at slaughter. Animal Production Science,49(2), 154–161.

Kudahettige-Nilsson, R. L., Helmerius, J., Nilsson, R. T., Sjöblom, M., Hodge, D. B., & Rova, U. (2015). Biobutanol production by Clostridium acetobutylicum using xylose recovered from birch Kraft black liquor. Bioresource Technology,176, 71–79.

Dwidar, M., Lee, S., & Mitchell, R. J. (2012). The production of biofuels from carbonated beverages. Applied Energy,100, 47–51.

Raganati, F., Procentese, A., Montagnaro, F., Olivieri, G., & Marzocchella, A. (2015). Butanol production from leftover beverages and sport drinks. Bioenergy Research,8(1), 369–379.

Dhamole, P. B., Mane, R. G., & Feng, H. (2015). Screening of non-ionic surfactant for enhancing biobutanol production. Applied Biochemistry and Biotechnology,177(6), 1272–1281.

Napoli, F., Marzocchella, A., Salatino, P. (2012). 6.1 Optimization of solvent recovery in the production of butanol by fermentation. Dottorando: Ing. Fabio Napoli Relatore: Prof. Antonio Marzocchella Prof. Piero Salatino Coordinatore: Prof. Ettore Benedetti, 92.

Napoli, F., Olivieri, G., Russo, M. E., Marzocchella, A., & Salatino, P. (2012). Continuous lactose fermentation by Clostridium acetobutylicum—assessment of energetics and product yields of the acidogenesis. Enzyme and Microbial Technology,50(3), 165–172.

Ezeji, T. C., Qureshi, N., & Blaschek, H. P. (2007). Bioproduction of butanol from biomass: from genes to bioreactors. Current Opinion in Biotechnology,18(3), 220–227.

Qureshi, N., & Maddox, I. (2005). Reduction in butanol inhibition by perstraction: utilization of concentrated lactose/whey permeate by Clostridium acetobutylicum to enhance butanol fermentation economics. Food and Bioproducts Processing,83(1), 43–52.

Adhami, L., Griggs, B., Himebrook, P., & Taconi, K. (2009). Liquid–liquid extraction of butanol from dilute aqueous solutions using soybean-derived biodiesel. Journal of the American Oil Chemists' Society,86(11), 1123–1128.

Taconi, K. A., Venkataramanan, K. P., & Johnson, D. T. (2009). Growth and solvent production by Clostridium pasteurianum ATCC® 6013™ utilizing biodiesel-derived crude glycerol as the sole carbon source. Environmental Progress & Sustainable Energy,28(1), 100–110.

Dhamole, P. B., Wang, Z., Liu, Y., Wang, B., & Feng, H. (2012). Extractive fermentation with non-ionic surfactants to enhance butanol production. Biomass and Bioenergy,40, 112–119.

Singh, K., Gedam, P. S., Raut, A. N., Dhamole, P. B., Dhakephalkar, P., & Ranade, D. R. (2017). Enhanced n-butanol production by Clostridium beijerinckii MCMB 581 in presence of selected surfactant. 3 Biotech,7, 161.

Gedam, P.S., Raut, A.N., Dhamole, P.B. (2018). Effect of operating conditions and immobilization on butanol enhancement in an extractive fermentation using non-ionic surfactant. Applied Biochemistry and Biotechnology, 1-13.

Raut, A. N., Gedam, P. S., & Dhamole, P. B. (2018). Determination of phase transition temperatures of PEO-PPO-PEO block copolymer L62 in presence of fermentation media components. Fluid Phase Equilibria,460, 126–134.

Qureshi, N., Schripsema, J., Lienhardt, J., & Blaschek, H. (2000). Continuous solvent production by Clostridium beijerinckii BA101 immobilized by adsorption onto brick. World Journal of Microbiology and Biotechnology,16(4), 377–382.

Yen, H. W., & Li, R. J. (2011). The effects of dilution rate and glucose concentration on continuous acetone–butanol–ethanol fermentation by Clostridium acetobutylicum immobilized on bricks. Journal of Chemical Technology & Biotechnology,86(11), 1399–1404.

Zhuang, W., Liu, X., Yang, J., Wu, J., Zhou, J., Chen, Y., Liu, D., & Ying, H. (2017). Immobilization of Clostridium acetobutylicum onto natural textiles and its fermentation properties. Microbial Biotechnology,10(2), 502–512.

Zeng, H.-S., He, C.-R., Yen, A., Wu, T.-M., & Li, S.-Y. (2016). Assessment of acidified fibrous immobilization materials for improving acetone-butanol-ethanol (ABE) fermentation. Fermentation,3(1), 3.

Chen, Y., Zhou, T., Liu, D., Li, A., Xu, S., Liu, Q., Li, B., & Ying, H. (2013). Production of butanol from glucose and xylose with immobilized cells of Clostridium acetobutylicum. Biotechnology and Bioprocess Engineering,18(2), 234–241.

Jesionowski, T., Zdarta, J., & Krajewska, B. (2014). Enzyme immobilization by adsorption: a review. Adsorption,20(5-6), 801–821.

Karimpil, J. J., Melo, J., & D’Souza, S. (2012). Immobilization of lipase on cotton cloth using the layer-by-layer self-assembly technique. International Journal of Biological Macromolecules,50(1), 300–302.

Manohar, S., Kim, C., & Karegoudar, T. (2001). Enhanced degradation of naphthalene by immobilization of Pseudomonas sp. strain NGK1 in polyurethane foam. Applied Microbiology and Biotechnology,55(3), 311–316.

He, Q., & Chen, H. Z. (2013). Improved efficiency of butanol production by absorbent fermentation with a renewable carrier. Biotechnology for Biofuels,6(1), 121.

Cheng, C.-L., Che, P.-Y., Chen, B.-Y., Lee, W.-J., Chien, L.-J., & Chang, J.-S. (2012). High yield bio-butanol production by solvent-producing bacterial microflora. Bioresource Technology,113, 58–64.

Raut, A. N., Gedam, P. S., & Dhamole, P. B. (2018). Back-extraction of butanol from coacervate phase using Winsor III microemulsion. Process Biochemistry,70, 160–167.

Miller, G. L. (1959). Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry,31(3), 426–428.

OTI, W.J. Using refractometer to determine the sugar content in soft drinks commonly consumed in Abakaliki, Nigeria.

Spagnolo, F. (1953). Spectrophotometric determination of glycerol as sodium-cupri-glycerol complex. Analytical Chemistry,25(10), 1566–1568.

Edwards, V. H. (1970). The influence of high substrate concentrations on microbial kinetics. Biotechnology and Bioengineering,12(5), 679–712.

D’souza, S. (2002). Trends in immobilized enzyme and cell technology.

Marshall, K.C., Breznak, J. (1984). Microbial adhesion and aggregation, Dahlem Workshop on Microbial Adhesion and Aggregation, Springer-Verlag, 1984.

D’souza, S. (1999). Immobilized enzymes in bioprocess. Current Science, 69-79.

Welsh, F., Williams, R., & Veliky, I. (1987). Solid carriers for a Clostridium acetobutylicum that produces acetone and butanol. Enzyme and Microbial Technology,9(8), 500–502.

Laube, V., Groleau, D., & Martin, S. (1984). The effect of yeast extract on the fermentation of glucose to 2, 3-butanediol by Bacillus polymyxa. Biotechnology Letters,6(8), 535–540.

Amador-Noguez, D., Brasg, I. A., Feng, X.-J., Roquet, N., & Rabinowitz, J. D. (2011). Metabolome remodeling during the acidogenic-solventogenic transition in Clostridium acetobutylicum. Applied and Environmental Microbiology,77(22), 7984–7997.

Funding

Pradip B. Dhamole would like to thank Department of Biotechnology (Govt. of India) for funding this work (vide Sanction order No. BT/PR5886/PBD/26/304/2012 dated 26 December 2013).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gedam, P.S., Raut, A.N. & Dhamole, P.B. Enhanced Butanol Production Using Non-ionic Surfactant–Based Extractive Fermentation: Effect of Substrates and Immobilization of Cell. Appl Biochem Biotechnol 189, 1209–1222 (2019). https://doi.org/10.1007/s12010-019-03069-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-019-03069-z