Abstract

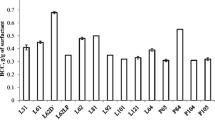

The present study was undertaken in order to investigate effect of diverse parameters such as fermentation media, pH, initial concentration of biomass, different surfactant concentrations, and immobilization on increasing butanol and total solvent production. Cheng’s fermentation media was successfully tested and perceived to increase final solvents concentration. Controlled pH at 12th and 24th hours had negative effect on butanol enhancement; however, it resulted in more butyric acid production which remained accumulated. Ten percent (v/v) biomass was evaluated to increase final solvents concentration and hence butanol yield compared to 20% and 30% (v/v) of initial biomass concentrations. Effect of surfactant concentration (3–20%) was studied on butanol production. Six percent (v/v) L62 resulted in 49% higher final butanol concentration compared to control. Simultaneous immobilization and fermentation showed higher butanol production (16.8 g/L with 6%) which was attributed to partial immobilization of biomass.

Similar content being viewed by others

References

D’souza, S. (2002). Trends in immobilized enzyme and cell technology. Indian Journal of Biotechnology, 1, 321–338.

Dürre, P. (1998). New insights and novel developments in clostridial acetone/butanol/isopropanol fermentation. Applied Microbiology and Biotechnology, 49, 639–648.

Zverlov, V., Berezina, O., Velikodvorskaya, G., & Schwarz, W. (2006). Bacterial acetone and butanol production by industrial fermentation in the Soviet Union: use of hydrolyzed agricultural waste for biorefinery. Applied Microbiology and Biotechnology, 71(5), 587–597.

Jones, D. T., & Woods, D. R. (1986). Acetone-butanol fermentation revisited. Microbiological Reviews, 50, 484–524.

Qureshi, N., & Maddox, I. (2005). Reduction in butanol inhibition by perstraction: utilization of concentrated lactose/whey permeate by Clostridium acetobutylicum to enhance butanol fermentation economics. Food and Bioproducts Processing, 83(1), 43–52.

Antoni, D., Zverlov, V. V., & Schwarz, W. H. (2007). Biofuels from microbes. Applied Microbiology and Biotechnology, 77(1), 23–35.

Kujawska, A., Kujawski, J., Bryjak, M., & Kujawski, W. (2015). ABE fermentation products recovery methods—a review. Renewable and Sustainable Energy Reviews, 48, 648–661.

Dhamole, P. B., Mane, R. G., & Feng, H. (2015). Screening of non-ionic surfactant for enhancing biobutanol production. Applied Biochemistry and Biotechnology, 177(6), 1272–1281.

Awang, G. M., Jones, G., Ingledew, W., & Kropinski, A. (1988). The acetone-butanol-ethanol fermentation. CRC Critical Reviews in Microbiology, 15(sup1), S33–S67.

Ezeji, T. C., Qureshi, N., & Blaschek, H. P. (2007). Bioproduction of butanol from biomass: from genes to bioreactors. Current Opinion in Biotechnology, 18(3), 220–227.

Adhami, L., Griggs, B., Himebrook, P., & Taconi, K. (2009). Liquid–liquid extraction of butanol from dilute aqueous solutions using soybean-derived biodiesel. Journal of the American Oil Chemists' Society, 86(11), 1123–1128.

Taconi, K. A., Venkataramanan, K. P., & Johnson, D. T. (2009). Growth and solvent production by Clostridium pasteurianum ATCC® 6013™ utilizing biodiesel-derived crude glycerol as the sole carbon source. Environmental Progress & Sustainable Energy, 28(1), 100–110.

Dhamole, P. B., Wang, Z., Liu, Y., Wang, B., & Feng, H. (2012). Extractive fermentation with non-ionic surfactants to enhance butanol production. Biomass and Bioenergy, 40, 112–119.

Singh, K., Gedam, P. S., Raut, A. N., Dhamole, P. B., Dhakephalkar, P., & Ranade, D. R. (2017). Enhanced n-butanol production by Clostridium beijerinckii MCMB 581 in presence of selected surfactant. 3 Biotech, 7, 161.

Dolejš, I., Rebroš, M., & Rosenberg, M. (2014). Immobilisation of Clostridium spp. for production of solvents and organic acids. Chemical Papers, 68(1), 1–14.

Jiang, L., Wang, J., Liang, S., Wang, X., Cen, P., & Xu, Z. (2009). Butyric acid fermentation in a fibrous bed bioreactor with immobilized Clostridium tyrobutyricum from cane molasses. Bioresource Technology, 100(13), 3403–3409.

Najafpour, G. (2006). Immobilization of microbial cells for the production of organic acid and ethanol. Biochemical Engineering and Biotechnology, 8, 199–227.

Djukić-Vuković, A. P., Mojović, L. V., Jokić, B. M., Nikolić, S. B., & Pejin, J. D. (2013). Lactic acid production on liquid distillery stillage by Lactobacillus rhamnosus immobilized onto zeolite. Bioresource Technology, 135, 454–458.

Chen, Y., Zhou, T., Liu, D., Li, A., Xu, S., Liu, Q., Li, B., & Ying, H. (2013). Production of butanol from glucose and xylose with immobilized cells of Clostridium acetobutylicum. Biotechnology and Bioprocess Engineering, 18(2), 234–241.

Laube, V., Groleau, D., & Martin, S. (1984). The effect of yeast extract on the fermentation of glucose to 2, 3-butanediol by Bacillus polymyxa. Biotechnology Letters, 6(8), 535–540.

Cheng, C.-L., Che, P.-Y., Chen, B.-Y., Lee, W.-J., Chien, L.-J., & Chang, J.-S. (2012). High yield bio-butanol production by solvent-producing bacterial microflora. Bioresource Technology, 113, 58–64.

Singh, K. G., Lapsiya, K. L., Gophane, R. R., & Ranade, D. R. (2017). Optimization for butanol production using Plackett-Burman design coupled with central composite design by Clostridium beijerenckii strain CHTa isolated from distillery waste manure. International Research Journal of Biochemical Technology, 3, 1–7.

Yang, X., Tu, M., Xie, R., Adhikari, S., & Tong, Z. (2013). A comparison of three pH control methods for revealing effects of undissociated butyric acid on specific butanol production rate in batch fermentation of Clostridium acetobutylicum. AMB Express, 3(1), 3.

Al-Shorgani, N. K. N., Kalil, M. S., Yusoff, W. M. W., & Hamid, A. A. (2017). Impact of pH and butyric acid on butanol production during batch fermentation using a new local isolate of Clostridium acetobutylicum YM1. Saudi Journal of Biological Sciences, 25, 339–348.

Jones, D. T. & Woods, D. R. (1989). In N. P. Minton, & D. J. Clarke (Eds.), Clostridia (pp. 105–144). Boston: Springer US.

Li, T., Yan, Y., & He, J. (2014). Reducing cofactors contribute to the increase of butanol production by a wild-type Clostridium sp. strain BOH3. Bioresource Technology, 155, 220–228.

Amador-Noguez, D., Brasg, I. A., Feng, X.-J., Roquet, N., & Rabinowitz, J. D. (2011). Metabolome remodeling during the acidogenic-solventogenic transition in Clostridium acetobutylicum. Applied and Environmental Microbiology, 77(22), 7984–7997.

Geng, Q., & Park, C.-H. (1993). Controlled-pH batch butanol-acetone fermentation by low acid producing Clostridium acetobutylicum B18. Biotechnology Letters, 15(4), 421–426.

Dada, O., Kalil, M., & Yusoff, W. (2012). Effects of inoculum and substrate concentrations in anaerobic fermentation of treated rice bran to acetone, butanol and ethanol. Bacteriology Journal, 2(4), 79–89.

Lee, J.-E., Seo, E.-J., Kweon, D.-H., Park, K.-M., & Jin, Y.-S. (2009). Fermentation of rice bran and defatted rice bran for butanol production using Clostridium beijerinckii NCIMB 8052. Journal of Microbiology and Biotechnology, 19(5), 482–490.

Raut, A. N., Gedam, P. S., & Dhamole, P. B. (2018). Determination of phase transition temperatures of PEO-PPO-PEO block copolymer L62 in presence of fermentation media components. Fluid Phase Equilibria, 25, 126–134.

Wang, Z., & Feng, H. (2010). Double cloud point of ethylene oxide–propylene oxide triblock copolymer in an aqueous solution. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 362(1–3), 110–116.

D’souza, S. (1999). Immobilized enzymes in bioprocess. Current Science, 77(1), 69–79.

Dhamole, P. B., Wang, B., & Feng, H. (2013). Detoxification of corn stover hydrolysate using surfactant-based aqueous two phase system. Journal of Chemical Technology and Biotechnology, 88(9), 1744–1749.

Flemming, H.-C., & Wingender, J. (2010). The biofilm matrix. Nature Reviews Microbiology, 8(9), 623–633.

Funding

This work received funding from the Department of Biotechnology (Govt. of India) (vide sanction order no. BT/PR5886/PBD/26/304/2012 dated 26.12.2013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gedam, P.S., Raut, A.N. & Dhamole, P.B. Effect of Operating Conditions and Immobilization on Butanol Enhancement in an Extractive Fermentation Using Non-ionic Surfactant. Appl Biochem Biotechnol 187, 1424–1436 (2019). https://doi.org/10.1007/s12010-018-2892-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-018-2892-2