Abstract

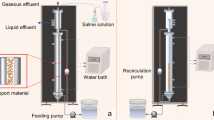

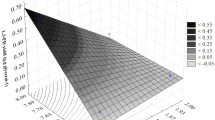

This study evaluated the propionic acid (HPr) production from crude glycerol (CG) (5000 mg L−1) in an anaerobic fluidized bed reactor (AFBR). Grounded tire particles (2.8–3.35 mm) were used as support material for microbial adhesion. The reactor was operated with hydraulic retention times (HRT) varying from 8 to 0.5 h under mesophilic (30 °C) conditions. The HPr was the main metabolite produced, increasing in composition from 66.5 to 99.6% by decreasing the HRT from 8 to 0.5 h. Other metabolic products were 1,3-propanediol, with a maximum of 29.4% with an HRT of 6 h, ethanol, acetic, and butyric acids. The decrease in HRT from 8 to 0.5 h decreased the HPr yield, with a maximum of 0.48 ± 0.06 g HPr g COD−1 and an HRT of 6 h, and favored HPr productivity, with a maximum of 4.09 ± 1.24 g L−1 h−1 and HRT of 0.5 h. In the biogas, the H2 content increased from 12.5 to 81.2% by decreasing the HRT from 8 to 0.5 h. These results indicate the potential application of the AFBR for HPr production using an immobilized mixed culture.

Similar content being viewed by others

References

Sorate, K. A., & Bhale, P. V. (2015). Biodiesel properties and automotive system compatibility issues. Renewable & Sustainable Energy Reviews, 41, 777–798.

ANP-National Agency of Oil, Natural Gas and Biofuels (Brazil). (2016) Brazilian Statistical Yearbook of Oil, Natural Gas and Biofuels, 1st ed National Agency of Oil, Natural gas and biofuels, Rio de Janeiro, Brazil (in Portuguese).

da Silva, G. P., Mack, M., & Contiero, J. (2009). Glycerol: a promising and abundant carbon source for industry microbiology. Biotechnology Advances, 27(1), 30–39.

Amaral, P. F. F., Ferreira, T. F., Fontes, G. C., & Coelho, M. A. Z. (2009). Glycerol valorization: new biotechnological routes. Food and Bioproducts Processin, 87(3), 179–186.

Boyaval, P., & Corre, C. (1995). Production of propionic acid. Le Lait, 75(4-5), 453–461.

Ahmadi, N., Khosravi-Darani, K., & Mortazavian, A. M. (2017). An overview of biotechnological production of propionic acid: from upstream to downstream processes. Electronic Journal of Biotechnology, 28, 67–75.

Barbirato, F., Chedaille, D., & Bories, A. (1997). Propionic acid fermentation from glycerol comparison with conventional substrates. Applied Microbiology and Biotechnology, 47(4), 441–446.

Liu, Y., Zhang, Y. G., Zhang, R. B., Zhang, F., & Zhu, J. (2011). Glycerol/glucose co-fermentation: On more proficient process to produce propionic acid by Propionibacterium acidipropionici. Current Microbiology, 62(1), 152–158.

Dishisha, T., Alvarez, M. T., & Hatti-Kaul, R. (2012). Batch- and continuous propionic acid production from glycerol using free and immobilized cells of Propionibacterium acidipropionici. Bioresource Technology, 118, 553–562.

Wang, Z., & Yang, S. T. (2013). Propionic acid production in glycerol/glucose co-fermentation by Propionibacterium freudenreichii subsp shermanii. Bioresource Technology, 137, 116–123.

Wang, Z., Jin, Y., & Yang, S. T. (2015). High cell density propionic acid fermentation with an acid tolerant strain of Propionibacterium acidipropionici. Biotechnology and Bioengeneering, 112(3), 502–511.

Zhang, Z. P., Tay, J. H., Show, K. Y., Yan, R., Liang, D. T., Lee, D. J., & Jiang, W. J. (2007). Biohydrogen production in a granular activated carbon anaerobic fluidized bed reactor. International Journal of Hydrogen Energy, 32(2), 185–191.

Amorim, E. L. C., Barros, A. R., Damianovic, M. H. R. Z., & Silva, E. L. (2009). Anaerobic fluidized bed reactor with expanded clay as support for hydrogen production through dark fermentation of glucose. International Journal of Hydrogen Energy, 34, 783–790.

Barros, A. R., Adorno, M. A. T., Sakamoto, I. K., Maintinguer, S. I., Varesche, M. B. A., & Silva, E. L. (2011). Performance evaluation and phylogenetic characterization of anaerobic fluidized bed reactors using ground tire and pet as support materials for biohydrogen production. Bioresource Technology, 102(4), 3840–3847.

Kim, S., Han, S., & Shin, H. (2006). Effect of substrate concentration on hydrogen production and 16S rDNA-based analysis of the microbial community in a continuous fermenter. Process Biochemistry, 41(1), 199–207.

Walker, M., Zhang, Y., Heaven, S., & Banks, C. (2009). Potential errors in the quantitative evaluation of biogas production in anaerobic digestion process. Bioresource Technology, 100, 116–123.

Penteado, E. D., Lazaro, C. Z., Sakamoto, I. K., & Zaiat, M. (2013). Influence of seed sludge and pretreatment method on hydrogen production in packed-bed anaerobic reactors. International Journal of Hydrogen Energy, 38(14), 6137–6145.

Bondiolli, P., & Della Bella, L. (2005). An alternative spectrophotometric method for the determination of free glycerol in biodiesel. European Journal of Lipid Science and Technology, 107(3), 153–157.

American Public Health Association. (2012). Standard methods for the examination for water and wastewater (22nd ed.). Washington: American Water Works Association, Water Environmental Federation.

van Haandel, A. and van der Lubbe, J. (2011) Handbook biological wastewater treatment: design and optimization of activated sludge systems. 1. ed. Leidschendam: Quist, Netherlands.

Gonen, C., Gungormusler, M., & Azbar, N. (2012). Comparative evaluation of pumice stone as an alternative immobilization material for 1,3-propanodiol production from waste glycerol by immobilized Klebsiella pneumonia. Applied Biochemistry and Biotechnology, 168(8), 2136–2147.

Gungormusler, M., Gonen, C., & Azbar, N. (2013). Effect of cell immobilization on the production of 1,3-propanediol. New Biotechnology, 30(6), 623–628.

Chookaew, T., O-Thong, S., & Prasertsan, P. (2014). Biohydrogen production from crude glycerol by immobilized by Klebsiella sp TR17 in a UASB reactor and bacterial quantification under non-sterile conditions. International Journal of Hydrogen Energy, 39(18), 9580–9587.

Gallardo, R., Faria, C., Rodrigues, L. R., Pereira, M. A., & Alves, M. M. (2014). Anaerobic granular sludge as a biocatalyst for 1,3-propanediol production from glycerol in continuous bioreactors. Bioresource Technology, 155, 28–33.

Biebl, H., Menzel, K., Zeng, A. P., & Deckwer, W. D. (1999). Microbial production of 1,3-propanediol. Applied Microbiology and Biotechnology, 52(3), 289–297.

Playne, M. J. (1985). Propionic and butyric acids. In M. Moon-Young (Ed.), Comprehensive biotechnology (pp. 731–759). New York: Pergamon Press.

Coral, J., Karp, S. G., Vandenberghe, L. P. S., Parada, J. L., Pandey, A., & Soccol, C. R. (2008). Batch fermentation model of propionic acid production by Propionibacterium acidipropionici in different carbon sources. Applied Microbiology and Biotechnology, 151, 333–341.

Himmi, E. H., Bories, A., Boussaid, A., & Hassani, L. (2000). Propionic acid fermentation of glycerol and glucose by Propionibacterium acidipropionici and Propionibacterium freudenreichii ssp Shermanii. Applied Microbiology and Biotechnology, 53(4), 435–440.

Emmanuel, B. (1978). The relative contribution of propionate, and long chain even-numbered fatty acids to the production of long chain odd-numbered fatty acids in rumen bacteria. Biochimica et Biophysica Acta, 528(2), 239–246.

Selembo, P. A., Perez, J. M., Loyd, W. A., & Logan, B. E. (2009). Enhanced hydrogen and 1,3-propanediol production from glycerol by fermentation using mixed cultures. Biotechnology and Bioengeneering, 104(6), 1098–1106.

Lo, Y. C., Chen, J. X., Huang, C. Y., Yuan, Y. J., & Chang, J. S. (2013). Dark fermentative hydrogen production with crude glycerol from biodiesel industry using indigenous hydrogen-producing bacteria. International Journal of Hydrogen Energy, 38(35), 15815–15822.

Hanaki, K., Matsuo, T., & Nagase, M. (1981). Mechanism of inhibition caused by long-chain fatty acids in anaerobic digestion process. Biotechnology and Bioengeneering, 23(7), 1591–1610.

Jeris, J. S., & Mccarty, P. L. (1965). The biochemistry of methane fermentation using C14 tracers. Journal of the Water Pollution Control Federation, 37, 178–192.

Novak, J. T., & Carlson, D. A. (1970). The kinetics of anaerobic long-chain fatty acids degradation. Journal of the Water Pollution Control Federation, 42, 1932–1943.

Demeyer, D. I., & Henderickx, H. K. (1966). The effect of C18 unsaturated fatty acids on methane production in vitro by mixed rumen bacteria. Biochimica et Biophysica Acta, 137, 484–497.

Kósmider, A., Drozdzynska, A., Blaszka, K., Leja, K., & Czaczyk, K. (2010). Propionic acid production by Propionibacterium freudenreichii ssp Shermanii using industrial wastes: crude glycerol and whey lactose. Polish Journal of Environmental Studies, 19, 1249–1253.

Dishisha, T., Ibrahim, M. H. A., Cavero, V. H., Alvarez, M. T., & Hatti-Kaul, R. (2015). Improved propionic acid production from glycerol: Combining cyclic batch- and sequential batch fermentations with optimal nutrient composition. Bioresource Technology, 176, 80–87.

Zhang, A., & Yang, S. T. (2009). Propionic acid production from glycerol by metabolically engineered Propionibacterium acidipropionici. Process Biochemistry, 44, 239–259.

Funding

The authors gratefully acknowledge the financial support of FAPEAM (Amazonas Research Foundation), CAPES (Coordination for the Improvement of Higher Education Personnel), CNPq (National Council for Scientific and Technological Development), and FAPESP (São Paulo Research Foundation).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nazareth, T.C., de Oliveira Paranhos, A.G., Ramos, L.R. et al. Valorization of the Crude Glycerol for Propionic Acid Production Using an Anaerobic Fluidized Bed Reactor with Grounded Tires as Support Material. Appl Biochem Biotechnol 186, 400–413 (2018). https://doi.org/10.1007/s12010-018-2754-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-018-2754-y