Abstract

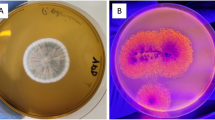

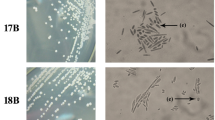

The coconut kernel-associated fungus, Lasiodiplodia theobromae VBE1, was grown on coconut cake with added coconut oil as lipase inducer under solid-state fermentation conditions. The extracellular-produced lipases were purified and resulted in two enzymes: lipase A (68,000 Da)—purified 25.41-fold, recovery of 47.1%—and lipase B (32,000 Da)—purified 18.47-fold, recovery of 8.2%. Both lipases showed optimal activity at pH 8.0 and 35 °C, were activated by Ca2+, exhibited highest specificity towards coconut oil and p-nitrophenyl palmitate, and were stable in iso-octane and hexane. Ethanol supported higher lipase activity than methanol, and n-butanol inactivated both lipases. Crude lipase immobilized by entrapment within 4% (w/v) calcium alginate beads was more stable than the crude-free lipase preparation within the range pH 2.5–10.0 and 20–80 °C. The immobilized lipase preparation was used to catalyze the transesterification/methanolysis of coconut oil to biodiesel (fatty acyl methyl esters (FAMEs)) and was quantified by gas chromatography. The principal FAMEs were laurate (46.1%), myristate (22.3%), palmitate (9.9%), and oleate (7.2%), with minor amounts of caprylate, caprate, and stearate also present. The FAME profile was comparatively similar to NaOH-mediated transesterified biodiesel from coconut oil, but distinctly different to petroleum-derived diesel. This study concluded that Lasiodiplodia theobromae VBE1 lipases have potential for biodiesel production from coconut oil.

Similar content being viewed by others

References

Sharma, R., Chisti, Y., & Banergee, V. C. (2002). Production, purification, characterization and applications of lipases. Biotechnology Advances, 19, 627–662.

Su, F., Peng, C., Li, G. L., Xu, L., & Yan, Y. J. (2016). Biodiesel production from woody oil catalyzed by Candida rugosa lipase in ionic liquid. Renewable Energy, 90, 329–335. https://doi.org/10.1016/j.renene.2016.01.029.

Norjannah, B., Ong, H. C., Masjuki, H. H., Juan, J. C., & Chong, W. T. (2016). Enzymatic transesterification for biodiesel production: a comprehensive review. RSC Advances, 6(65), 60034–60055. https://doi.org/10.1039/C6RA08062F.

Souza, L. T. A., Oliveira, J. S., Rodrigues, M. Q. R. B., Santos, V. L. D., Pessela, B. C., & Resende, R. R. (2015). Macaúba (Acrocomia aculeata) cake from biodiesel processing: a low-cost substrate to produce lipases from Moniliella spathulata R25L270 with potential application in the oleochemical industry. Microbial Cell Factories, 14(1), 87. https://doi.org/10.1186/s12934-015-0266-9.

Treichel, H., de Oliveira, D., Mazutti, M. A., Di Luccio, M., & Oliveira, J. V. (2010). A review on microbial lipases production. Food and Bioprocess Technology, 3(2), 182–196. https://doi.org/10.1007/s11947-009-0202-2.

Di Luccio, M., Capra, F., Ribeiro, N. P., Vargas, G. D. L. P., Freire, D. M. G., Denise, M. G., & De Oliveira, D. (2004). Effect of temperature, moisture, and carbon supplementation on lipase production by solid-state fermentation of soy cake by Penicillium simplicissimum. Applied Biochemistry and Biotechnology, 113(1-3), 173–180. https://doi.org/10.1385/ABAB:113:1-3:173.

Ul-Haq, I., Idrees, S., & Rajoka, M. I. (2002). Production of lipases by Rhizopus oligosporous by solid-state fermentation. Process Biochemistry, 37(6), 637–641. https://doi.org/10.1016/S0032-9592(01)00252-7.

Bogar, B., Szak’acs, G., Pandey, A., Abdulhameed, S., Linden, J. C., & Tengerdy, R. P. (2003). Production of phytase by Mucor racemosus in solid-state fermentation. Biotechnology Progress, 19(2), 312–319. https://doi.org/10.1021/bp020126v.

Mahadik, N. D., Puntambekar, U. S., Bastawde, K. B., Khire, J. M., & Gokhale, D. V. (2002). Production of acidic lipase by Aspergillus niger in solid state fermentation. Process Biochemistry, 38(5), 715–721. https://doi.org/10.1016/S0032-9592(02)00194-2.

Dominguez, A., Costas, M., Longo, M. A., & Sanroman, A. (2003). A novel application of solid state culture: production of lipases by Yarrowia lipolytica. Biotechnology Letters, 25(15), 1225–1229. https://doi.org/10.1023/A:1025068205961.

Venkatesagowda, B., Ponugupaty, E., Barbosa, A. M., & Dekker, R. F. H. (2012). Diversity of plant oil seed-associated fungi isolated from seven oil-bearing seeds and their potential for the production of lipolytic enzymes. World Journal of Microbiology and Biotechnology, 28(1), 71–80. https://doi.org/10.1007/s11274-011-0793-4.

Castilho, L. R., Polato, C. M. S., Baruque, E. A., Sant’Anna Jr., G. L., & Freire, D. M. G. (2000). Economic analysis of lipase production by Penicillium restrictum in solid-state and submerged fermentations. Biochemical Engineering Journal, 4(3), 239–247. https://doi.org/10.1016/S1369-703X(99)00052-2.

Venkatesagowda, B., Ponugupaty, E., Barbosa, A. M., & Dekker, R. F. H. (2015). Solid-state fermentation of coconut kernel-cake as substrate for the production of lipases by the coconut kernel-associated fungus Lasiodiplodia theobromae VBE-1. Annals of Microbiology, 65(1), 129–142. https://doi.org/10.1007/s13213-014-0844-9.

Kamini, N. R., Mala, J. G. S., & Puvanakrishnan, P. (1998). Lipase production from Aspergillus niger by solid-state fermentation using gingelly oil cake. Process Biochemistry, 33(5), 505–511. https://doi.org/10.1016/S0032-9592(98)00005-3.

Mahanta, N., Gupta, A., & Khare, S. K. (2008). Production of protease and lipase by solvent tolerant Pseudomonas aeruginosa PseA in solid state fermentation using Jatropha curcas seed cake as substrate. Bioresource Technology, 99(6), 1729–1735. https://doi.org/10.1016/j.biortech.2007.03.046.

Sethi, B. K., Rout, J. R., Das, R., Nanda, P. K., & Sahoo, S. L. (2013). Lipase production by Aspergillus terreus using mustard seed oil cake as a carbon source. Annals of Microbiology, 63(1), 241–252. https://doi.org/10.1007/s13213-012-0467-y.

Balaji, V., & Ebenezer, P. (2008). Optimization of extracellular lipase production in Colletotrichum gloeosporioides by solid state fermentation. Indian Journal of Science and Technology, 1, 1–8.

Babu, I. S., & Rao, G. H. (2007). Lipase production by Yarrowia lipolytica NCIM 3589 in solid state fermentation using mixed substrate. Research Journal of Microbiology, 5, 469–474.

Benjamin, S., & Pandey, A. (1998). Mixed-solid substrate fermentation. A novel process for enhanced lipase production by Candida rugosa. Acta Biotechnologica, 18(4), 315–324. https://doi.org/10.1002/abio.370180405.

Edwinoliver, N. G., Thirunavukarasu, K., Naidu, R. B., Gowthaman, M. K., Nakajima Kambe, T., & Kamini, N. R. (2010). Scale up of a novel tri-substrate fermentation for enhanced production of Aspergillus niger lipase for tallow hydrolysis. Bioresource Technology, 101(17), 6791–6796. https://doi.org/10.1016/j.biortech.2010.03.091.

Gutarra, M. L. E., Godoy, M. G., Castilho, L. R., & Freire, D. M. G. (2007). Inoculum strategies for Penicillium simplicissimum lipase production by solid-state fermentation using a residue from the babassu oil industry. Journal of Chemical Technology and Biotechnology, 82(3), 313–318. https://doi.org/10.1002/jctb.1674.

Uranga, C. C., Ghassemian, M., & Hernandez-Martínez, R. (2017). Novel proteins from proteomic analysis of the trunk disease fungus Lasiodiplodia theobromae (Botryosphaeriaceae). Biochimie Open, 4, 88–98. https://doi.org/10.1016/j.biopen.2017.03.001.

Kumar, A., & Kanwar, S. S. (2012). Lipase production in solid-state fermentation (SSF): recent developments and biotechnological applications. Dynamic Biochemistry, Process Biotechnology and Molecular Biology, 6, 13–27.

Ito, K., Gomi, K., & Kariyama, M. (2013). Rapid enzyme production and mycelial growth in solid-state fermentation using the non-airflow box. Journal of Bioscience and Bioengineering, 116(5), 585–590. https://doi.org/10.1016/j.jbiosc.2013.04.024.

Ban, K., Kaieda, M., Matsumoto, T., Kondo, A., & Fukuda, H. (2001). Whole cell biocatalyst for biodiesel fuel production utilizing Rhizopus oryzae cells immobilized within biomass support particles. Biochemical Engineering Journal, 8(1), 39–43. https://doi.org/10.1016/S1369-703X(00)00133-9.

Pizarro, P. A. V., & Park, E. Y. (2003). Lipase-catalyzed production of biodiesel fuel from vegetable oils contained in waste activated bleaching earth. Process Biochemistry, 38(7), 1077–1082. https://doi.org/10.1016/S0032-9592(02)00241-8.

Nurfitri, I., Maniam, G. P., Hindryawati, N., Yusoff, M. M., & Ganesan, S. (2013). Potential of feedstock and catalysts from waste in biodiesel preparation: a review. Energy Conversion and Management, 74, 395–402. https://doi.org/10.1016/j.enconman.2013.04.042.

Dias, J. M., Araújo, J. M., Costa, J. F., Alvim-Ferraz, M. C. M., & Almeida, M. F. (2013). Biodiesel production from raw castor oil. Energy, 53, 58–66. https://doi.org/10.1016/j.energy.2013.02.018.

Patil, P. D., & Deng, S. (2009). Optimization of biodiesel production from edible and non-edible vegetable oils. Fuel, 88(7), 1302–1306. https://doi.org/10.1016/j.fuel.2009.01.016.

Alptekin, E., & Canakci, M. (2010). Optimization of pretreatment reaction for methyl ester production from chicken fat. Fuel, 89(12), 4035–4039. https://doi.org/10.1016/j.fuel.2010.04.031.

Borowitzka, M. A., & Moheimani, N. R. (Eds.). (2013). Algae for Biofuels and Energy, developments in applied phycology 5 (p. 288). Dordrecht: Springer Science + Business Media. https://doi.org/10.1007/978-94-007-5479-9.

Liu, Y., Li, C., Wang, S., & Chen, W. (2014). Solid-supported microorganism of Burkholderia cenocepacia cultured via solid-state fermentation for biodiesel production: optimization and kinetics. Applied Energy, 113, 713–721. https://doi.org/10.1016/j.apenergy.2013.08.009.

Christopher, L. P., Kumar, V., & Zambare, V. P. (2012). Enzymatic biodiesel: Challenges and opportunities. Applied Energy, 119, 497–520.

Akoh, C. C., Chang, S. W., Lee, G. C., & Shaw, J. F. (2007). Enzymatic approach to biodiesel production. Journal of Agricultural and Food Chemistry, 55(22), 8995–9005. https://doi.org/10.1021/jf071724y.

Korman, T. P., Sahachartsiri, B., & Charbonneau, D. M. (2013). Dieselzymes: development of a stable and methanol tolerant lipase for biodiesel production by directed evolution. Biotechnology for Biofuels, 6(1), 70. https://doi.org/10.1186/1754-6834-6-70.

Yang, K. S., Sung, B. H., Park, M. K., Lee, J. H., Lim, K. J., Park, S. C., Kim, S. J., Kim, H. K., Sohn, J.-H., Kim, H. M., & Kim, S. C. (2015). Recombinant lipase engineered with amphipathic and coiled-coil peptides. ACS Catalysis, 5(9), 5016–5025. https://doi.org/10.1021/cs502079g.

Hobden, R. (2014). Commercializing enzymatic biodiesel production. Biodiesel Magazine, 11, 34–37.

Sommer, P., Bormann, C., & Gotz, F. (1997). Genetic and biochemical characterization of a new extracellular lipase from Streptomyces cinnamomeus. Applied and Environmental Microbiology, 63(9), 3553–3560.

Bradford, M. M. (1976). A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein dye binding. Analytical Biochemistry, 72(1-2), 248–254. https://doi.org/10.1016/0003-2697(76)90527-3.

Laemmli, U. K. (1970). Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature, 227(5259), 680–685. https://doi.org/10.1038/227680a0.

Blum, H., Beier, H., & Gross, H. J. (1987). Improved silver staining of plant proteins, RNA and DNA in polyacrylamide gels. Electrophoresis, 8(2), 93–99. https://doi.org/10.1002/elps.1150080203.

Davis, B. J. (1964). Disc electrophoresis II method and application to human serum proteins. Annals of the New York Academy of Sciences, 121, 404–423.

Brush, T. S., Chapman, R., Kurzman, R., & Williams, D. P. (1999). Purification and characterization of extracellular lipase from Ophiostoma piliferum. Bioorganic & Medicinal Chemistry, 10, 2131–2138.

Benjamin, S., & Pandey, A. (2001). Isolation and characterization of three distinct forms of lipases from Candida rugosa produced in solid state fermentation. Brazilian Archives of Biology and Technology, 44(2), 213–221. https://doi.org/10.1590/S1516-89132001000200016.

Mateos Diaz, J. C., Rodriguez, J. A., Roussos, S., Cordova, J., Abousalham, A., Carriere, F., & Baratti, J. (2006). Lipase from the thermotolerant fungus Rhizopus homothallicus is more thermostable when produced using solid state fermentation than liquid fermentation procedures. Enzyme and Microbial Technology, 39(5), 1042–1050. https://doi.org/10.1016/j.enzmictec.2006.02.005.

Lima, V. M. G., Krieger, N., Mitchell, D. A., & Fontana, J. D. (2004). Activity and stability of a crude lipase from Penicillium aurantiogriseum in aqueous media and organic solvents. Biochemical Engineering Journal, 18(1), 65–71. https://doi.org/10.1016/S1369-703X(03)00165-7.

Saxena, R. K., Davidson, W. S., Sheoran, A., & Giri, B. (2003). Purification and characterization of an alkaline thermostable lipase from Aspergillus carneus. Process Biochemistry, 39(2), 239–247. https://doi.org/10.1016/S0032-9592(03)00068-2.

Heerden, E. V., Litthaue, D., & Verger, R. (2002). Biochemical characterization and kinetic properties of a purified lipase from Aspergillus niger in bulk phase and monomolecular films. Enzyme and Microbial Technology, 30(7), 902–909. https://doi.org/10.1016/S0141-0229(02)00031-5.

Shu, C.-H., Xu, C.-H., & Lin, G.-C. (2006). Purification and partial characterization of a lipase from Antrodia cinnamomea. Process Biochemistry, 41(3), 734–738. https://doi.org/10.1016/j.procbio.2005.09.007.

Mehta, A., Saun, N. K., & Gupta, R. (2016). Purification and characterization of lipase from thermophilic Geobacillus sp. Current Biotechnology, 5(1), 81–89. https://doi.org/10.2174/2211550105666151222183051.

da Silva, V. C. F., Contesini, F. J., & Carvalho, P. D. O. (2008). Characterization and catalytic activity of free and immobilized lipase from Aspergillus niger: a comparative study. Journal of the Brazilian Chemical Society, 19(8), 1468–1474. https://doi.org/10.1590/S0103-50532008000800005.

Hiol, A., Jonzo, M. D., & Comeau, L. (1999). Production, purification and characterization of an extracellular lipase from Mucor hiemalis f. hiemalis. Enzyme and Microbial Technology, 25(1-2), 80–87. https://doi.org/10.1016/S0141-0229(99)00009-5.

Abbas, H., Hiol, A., Deyris, V., & Comeau, L. (2002). Isolation and characterization of an extracellular lipase from Mucor sp. strain isolated from palm fruit. Enzyme and Microbial Technology, 31(7), 968–975. https://doi.org/10.1016/S0141-0229(02)00190-4.

Benjamin, S., & Pandey, A. (2000). Isolation and characterization of three distinct forms of lipases from Candida rugosa produced in solid state fermentation. Brazilian Archives of Biology and Technology, 43(5), 453–460. https://doi.org/10.1590/S1516-89132000000500002.

Sharma, S., & Kanwar, S. S. (2014). Organic solvent tolerant lipases and applications. The Scientific World Journal, article ID, 625258, 15.

Kumar, A., Dhar, K., Kanwar, S. S., & Arora, P. K. (2016). Lipase catalysis in organic solvents: advantages and applications. Biological Procedures Online, 18(1), 2. https://doi.org/10.1186/s12575-016-0033-2.

Ribeiro, B. D., de Castro, A. M., Coelho, M. A. Z., & Freire, D. M. G. (2011). Production and use of lipases in bioenergy: a review from the feedstocks to biodiesel production. Enzyme Research, 2011; ID 615803, 16.

Nakpong, P., & Wootthikanokkhan, S. (2010). High free fatty acid coconut oil as a potential feedstock for biodiesel production in Thailand. Renewable Energy, 35(8), 1682–1687. https://doi.org/10.1016/j.renene.2009.12.004.

Tupufia, S. C., Jeon, Y. J., Marquis, C., Adesina, A. A., & Rogers, P. L. (2013). Enzymatic conversion of coconut oil for biodiesel production. Fuel Processing Technology, 106, 721–726. https://doi.org/10.1016/j.fuproc.2012.10.007.

Winayanuwattikun, P., Kaewpiboon, C., Piriyakananon, K., Tantong, S., Thakernkarnkit, W., Chulalaksananukul, W., & Yongvanich, T. (2008). Potential plant oil feedstock for lipase-catalyzed biodiesel production in Thailand. Biomass and Bioenergy, 32(12), 1279–1286. https://doi.org/10.1016/j.biombioe.2008.03.006.

Lafont, J. J., Espitia, A. A., & Sodre, J. R. (2015). Potential vegetable oils sources for biodiesel production: cashew, coconut and cotton. Material Renewable Sustainable Energy, March, 4(1), 1. https://doi.org/10.1007/s40243-014-0041-6.

Giakoumis, E. G. (2013). A statistical investigation of biodiesel physical and chemical properties, and their correlation with the degree of unsaturation. Renewable Energy, 50, 858–878. https://doi.org/10.1016/j.renene.2012.07.040.

Acknowledgements

The authors acknowledge the Department of Chemistry, University of Madras and Indian Institute of Technology (IIT) Madras, and Central Leather Research Institute (CLRI), Adyar, Chennai, Tamil Nadu, India, for analysis of the biodiesel samples from coconut oil and commercial diesel. Professor R.F.H. Dekker gratefully acknowledges Universidade Tecnológica Federal do Paraná, Londrina-PR (Brazil) for support during the writing of the paper.

Funding

The University Grants Commission—Major Research Project at the University of Madras, INDIA, is acknowledged for financial support.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Venkatesagowda, B., Ponugupaty, E., Barbosa-Dekker, A.M. et al. The Purification and Characterization of Lipases from Lasiodiplodia theobromae, and Their Immobilization and Use for Biodiesel Production from Coconut Oil. Appl Biochem Biotechnol 185, 619–640 (2018). https://doi.org/10.1007/s12010-017-2670-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-017-2670-6