Abstract

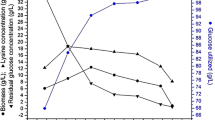

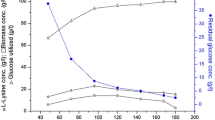

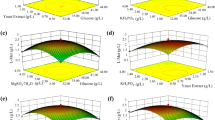

In this study, culture conditions, including dissolved oxygen (DO) content, presence of osmoprotectants, residual glucose concentration, and ammonium sulfate-feeding strategies, were investigated for decreasing the inhibition effects of acetic acid, ammonium, and osmotic stress on l-lysine fermentation by Escherichia coli. The results revealed that higher DO content and lower residual glucose concentration could decrease acetic acid accumulation, betaine supplementation could enhance osmotic stress tolerance, and variable speed ammonium sulfate-feeding strategy could decrease ammonium inhibition. Thus, with 25 % DO content, 0–5.0 g/L of residual glucose concentration, and 1.5 g/L of betaine supplementation, 134.9 g/L of l-lysine was obtained after 72 h of culture, with l-lysine yield and productivity of 45.4 % and 1.9 g/(L · h), respectively.

Similar content being viewed by others

References

Brautaset, T., & Ellingsen, T. E. (2011). Industrial biotechnology and commodity products. In M. Y. Murray (Ed.), Comprehensive Biotechnology (Vol. 3, pp. 541–554). New York: Elsevier.

Becker, J., Klopprogge, C., & Wittmann, C. (2009). Applied and Environmental Microbiology, 75, 7866–7869.

Eggeling, L., & Sahm, H. (1999). Applied Microbiology and Biotechnology, 52, 146–153.

Wittmann, C., and Becker, J. (2007). Biosynthesis—pathways, regulation and metabolic engineering. In: Volker, F.W. (eds). Microbiology monographs, vol. 5: Amino acid. Springer: New York. pp. 39–70.

Lee, G. H., Hur, W., & Flickinger, M. C. (1996). Biotechnology and Bioengineering, 49, 639–653.

Xu, D. Q., Tan, Y. Z., & Huan, X. J. (2009). Journal of Microbiological Methods, 80, 86–92.

Sassi, A. H., Fauvart, L., & Deschamps, A. M. (1998). Biochemical Engineering Journal, 1, 85–90.

Nadeem, S., Ikaram, A., & Yaqoob, N. (2001). International Journal of Agriculture and Biology, 4, 448–450.

Mey, M. D., Maeseneire, S. D., & Sortaert, W. (2007). Journal of Industrial Microbiology, 34, 689–700.

Hanning, G., & Makrides, S. C. (1998). Trends in Biotechnology, 16, 54–60.

Khamduang, M., Packdibamrung, K., & Chutmanop, J. (2009). Journal of Industrial Microbiology & Biotechnology, 36, 1267–1274.

Patnaik, R., Zolandz, R. R., & Green, D. A. (2008). Biotechnology and Bioengineering, 99, 741–752.

Zhao, Z. J., Zou, C., & Zhu, Y. X. (2011). Journal of Industrial Microbiology & Biotechnology, 38, 1921–1929.

Imaizumi, A., Takikawa, R., & Koseki, C. (2005). Journal of Biotechnology, 117, 111–118.

Nagai, Y., and Masumitsu, Y. (2008). EP2202299.

Mika, J. T. (2012). Molecule diffusion in bacteria and consequences of osmotic stress (pp. 10–14). Groningen: University of Groningen.

Thompson, B. G., Kole, M., & Gerson, O. (1985). Biotechnology and Bioengineering, 27, 818–824.

Han, K., Lim, H. C., & Hong, J. (1992). Biotechnology and Bioengineering, 39, 663–671.

Saurina, J., Cassou, S. H., & Alegtet, S. (1999). Biosensors & Bioelectronics, 14, 211–220.

Suarez, D. C., & Kilikian, B. V. (2000). Process Biochemistry, 35, 1051–1055.

Korz, D. J., Rinas, U., & Hellmuth, K. (1995). Journal of Biotechnology, 39, 59–65.

Padan, E., & Krulwich, T. A. (2000). Sodium stress (pp. 117–130). Washington DC: ASM Press.

Shiloach, J., Kaufman, J., & Fass, R. (1996). Biotechnology and Bioengineering, 49, 421–428.

Ronsch, H., Kramer, R., & Morbach, S. (2003). Journal of Biotechnology, 104, 87–97.

Kunte, H. J., Crane, R. A., & Culham, D. E. (1999). Journal of Bacteriology, 181, 1537–1543.

Mutsumi, T., Yoshinori, N., & Gyuseop, O. (1996). Biotechnology and Bioengineering, 52, 653–660.

Acknowledgments

This work was supported by the National Nature Science Foundation of China (grant no. 21106066, 21106068), National Key Technology Support Program (grant no. 2012BAI44G00), “973” program of China (grant no. 2011CBA00807), and Nature Science Foundation of Jiangsu High School (11KJB530003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ying, H., He, X., Li, Y. et al. Optimization of Culture Conditions for Enhanced Lysine Production Using Engineered Escherichia coli . Appl Biochem Biotechnol 172, 3835–3843 (2014). https://doi.org/10.1007/s12010-014-0820-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-014-0820-7