Abstract

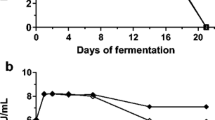

Studies have been conducted on selecting yeast strains for use in fermentation for ethanol production to improve the performance of industrial plants and decrease production costs. In this paper, we study alcoholic fermentation in a fed-batch process using a Saccharomyces cerevisiae yeast strain with flocculant characteristics. Central composite design (CCD) was used to determine the optimal combination of the variables involved, with the sucrose concentration of 170 g/L, a cellular concentration in the inoculum of 40 % (v/v), and a filling time of 6 h, which resulted in a 92.20 % yield relative to the theoretical maximum yield, a productivity of 6.01 g/L h and a residual sucrose concentration of 44.33 g/L. With some changes in the process such as recirculation of medium during the fermentation process and increase in cellular concentration in the inoculum after use of the CCD was possible to reduce the residual sucrose concentration to 2.8 g/L in 9 h of fermentation and increase yield and productivity for 92.75 % and 9.26 g/L h, respectively. A model was developed to describe the inhibition of alcoholic fermentation kinetics by the substrate and the product. The maximum specific growth rate was 0.103 h−1, with K I and K s values of 109.86 and 30.24 g/L, respectively. The experimental results from the fed-batch reactor show a good fit with the proposed model, resulting in a maximum growth rate of 0.080 h−1.

Similar content being viewed by others

References

Li, A. H., Lin, C. W., & Tran, D. T. (2011). Optimizing the response surface for producing ethanol from avicel by Brevibacillus strain AHPC8120. Journal of the Taiwan Institute of Chemical Engineers, 42, 787–792.

Andrade, R. R., Maugeri, F. F., Maciel Filho, R., & Costa, A. C. (2013). Kinetics of ethanol production from sugarcane bagasse enzymatic hydrolysate concentrated with molasses under cell recycle. Bioresource Technology, 130, 351–359.

Wu, L., Li, Y., Arakane, M., Ike, M., Wada, M., Terajima, Y., Ishikawa, S., & Tokuyasu, K. (2011). Efficient conversion of sugarcane stalks into ethanol employing low temperature alkali pretreatment method. Bioresource Technology, 102, 11183–11188.

Goldemberg, J., Coelho, S. T., & Guardabassi, P. (2008). The sustainability of ethanol production from sugarcane. Energy Policy, 36, 2086–2097.

Rolz, C., & León, R. (2011). Ethanol fermentation from sugarcane at different maturities. Industrial Crops and Products, 33, 333–337.

Martín, C., Galve, M., Fredrik, W. C., Hagerdal, B. H., & Jonsson, L. J. (2002). Ethanolproduction from enzymatic hydrolysates of sugarcane bagasse using recombinant xilose-utilizing Saccharomyces cerevisiae. Enzyme and Microbial Technology, 31, 274–282.

Chandel, A. K., Chan, E. S., Rudravaram, R., Narasu, M. L., Rao, L. V., & Pogaku, R. (2007). Economics and environmental impact of bio-ethanol production technologies: anappraisal. Biotechnology and Molecular Biology Reviews, 2, 14–32.

Behera, S., Kar, S., Mohanty, R. C., & Ramesh, R. C. (2010). Comparative study of bio-ethanol production from mahula (Madhucalatifolia L.) flowers by Saccharomyces cerevisiae cells immobilized in agar agar and Ca-alginate matrices. Applied Energy, 87, 96–100.

Najafpour, G., Younesi, H., & Ismail, K. S. K. (2004). Ethanol fermentation in an immobilized cell reactor using Saccharomyces cerevisiae. Bioresource Technology, 92, 251–260.

Ghorbani, F., Younesi, H., Sari, A. E., & Najafpour, G. (2011). Cane molasses fermentation for continuous ethanol production in an immobilized cells reactor by Saccharomyces cerevisiae. Renewable Energy, 36, 503–509.

Domingues, L., Vicente, A. A., Lima, N., & Teixeira, J. A. (2000). Applications of yeast flocculation in biotechnological processes. Biotechnology and Bioprocess, 5, 288–305.

Ginovart, M., López, D., Giró, A., & Silbert, M. (2006). Flocculation in brewing yeasts: A computer simulation study. Biosystems, 83, 51–55.

Bai, F. W., Anderson, W. A., & Moo-Young, M. (2008). Ethanol fermentation technologies from sugar and starch feedstocks. Biotechnology Advances, 26, 89–105.

Belloch, C., Orlic, S., Barrio, E., & Querol, A. (2008). Fermentative stress adaptation of hybrids within the Saccharomyces sensu stricto complex. International Journal of Food Microbiology, 29, 188–195.

Andrietta, S. R., Steckelberg, C., & Andrietta, M. G. S. (2008). Study of flocculent yeast performance in tower reactors for bio-ethanol production in a continuous fermentation process with no cell recycling. Bioresource Technology, 99, 3002–3008.

Amorim, H. V. (2005). Fermentação Alcoólica: Ciência e Tecnologia. Piracicaba: Fermentec. 448.

Converti, A., Arni, S., Sato, S., Carvalho, J. C. M., & Aquarone, E. (2003). Simplified modeling of fed-batch alcoholic fermentation of sugarcane blackstrap molasses. Biotechnology and Bioengineering, 84, 88–95.

Domingues, L.M.A.R. (2001) Estirpes floculantes de Saccharomyces cerevisiae geneticamente modificadas para a utilização da lactose: construção e aplicação biotecnológica. Thesis, Universidade do Minho, Minho, Portugal

Andrietta, S. R., Andrietta, M. G. S., Rodrigues M. I. (1995). Método de caracterização de leveduras de processo utilizando parâmetros cinéticos e produção específica. STAB—Açúcar, Álcool e Subprodutos, 13, pp. 22–25.

Finguerut, J.I. (2006) Workshop Brasileiro sobre Obtenção de Etanol. Projeto PPPP Etanol. Centro de Tecnologia Canavieira

Rodrigues, M. I, Iemma, A. F. (2007). Planejamento de Experimentos e Otimização de Processos. Campinas, 325.

Ghose, T. K., & Thyagi, R. D. (1979). Rapid ethanol fermentation of cellulose hydrolisate I. Batch versus continuous systems. Biotechnology and Bioengineering, 21, 1387–1400.

Tosetto, G. M. (2002). Influência da matéria-prima no comportamento cinético de levedura na produção de etanol. 147f. Dissertation, Faculty of Chemical Engineering, State University of Campinas, Campinas.

Tosetto, G. M., & Andrietta, S. R. (2002). Influência da matéria prima no comportamento cinético de levedura na produção de etanol. Apresentado no VII Seminar on Enzymatic Hidrolysis of Biomass—SHEB, Maringá.

Steckelberg, C. (2001). Caracterização de Leveduras de Processo de Fermentação Alcoólica Utilizando Atributos de Composição Celular e características Cinéticas. Thesis, StateUniversityof Campinas, Campinas.

Choi, G. W., Um, H. J., Kang, H. W., Kim, Y., Kim, M., & Kim, Y. H. (2010). Bio-ethanol production by a flocculent hybrid, CHFY0321 obtained by protoplast fusion between Saccharomyces cerevisiae and Saccharomyces bayanus. Biomass and Bioenergy, 34, 1232–1242.

Wang, B., Ge, X. M., Li, N., & Bai, F. W. (2006). Continuous ethanol fermentation coupled with recycling of yeast flocs. Chinese Journal of Biotechnology, 22, 816–821.

Ma, K., Wakisaka, M., Sakai, K., & Shirai, Y. (2009). Flocculation characteristics of an isolated mutant flocculent Saccharomyces cerevisiae strain and its application for fuel ethanol production from kitchen refuse. Bioresource Technology, 100, 2289–2292.

Gomes, D. G., Guimarães, P. M. R., Pereira, F. B., Teixeira, J. A., & Domingues, L. (2012). Plasmid-mediate transfer of FLO1 into industrial Saccharomyces cerevisiae PE-2 strain creates a strain useful for repeat-batch fermentations involving flocculation–sedimentation. Bioresource Technology, 108, 162–168.

Laluce, C., Tognolli, J. O., Oliveira, K. F., Souza, C. S., & Morais, M. R. (2009). Optimization of temperature, sugar concentration, and inoculum size to maximize ethanol production without significant decrease in yeast cell viability. Applied Microbiology and Biotechnology, 83, 627–637.

Pacheco T. F. (2010). Fermentação alcoólica com leveduras de características floculantes em reator tipo torre com escoamento ascendente, 94f. Dissertation, Faculty of Chemical Engineering, Federal University of Uberlândia, Uberlândia.

Ge, X. M., & Bai, F. W. (2006). Intrinsic kinetics of continuous growth and ethanol production of a flocculating fusant yeast strain SPSC01. Journal of Biotechnology, 124, 363–372.

Acknowledgments

The authors wish to thank the FAPEMIG, CNPq, and CAPES, Brazil for financial support and the CTC and CPQBA for donating the yeast strains.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guidini, C.Z., Marquez, L.D.S., de Almeida Silva, H. et al. Alcoholic Fermentation with Flocculant Saccharomyces cerevisiae in Fed-Batch Process. Appl Biochem Biotechnol 172, 1623–1638 (2014). https://doi.org/10.1007/s12010-013-0646-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-013-0646-8