Abstract

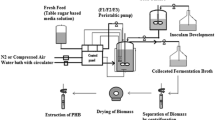

Polyhydroxybutyrate or PHB is a biodegradable and biocompatible thermoplastic with many interesting applications in medicine, food packaging, and tissue engineering materials. The present study deals with the enhanced production of PHB by Azohydromonas australica using sucrose and the estimation of fundamental kinetic parameters of PHB fermentation process. The preliminary culture growth inhibition studies were followed by statistical optimization of medium recipe using response surface methodology to increase the PHB production. Later on batch cultivation in a 7-L bioreactor was attempted using optimum concentration of medium components (process variables) obtained from statistical design to identify the batch growth and product kinetics parameters of PHB fermentation. A. australica exhibited a maximum biomass and PHB concentration of 8.71 and 6.24 g/L, respectively in bioreactor with an overall PHB production rate of 0.75 g/h. Bioreactor cultivation studies demonstrated that the specific biomass and PHB yield on sucrose was 0.37 and 0.29 g/g, respectively. The kinetic parameters obtained in the present investigation would be used in the development of a batch kinetic mathematical model for PHB production which will serve as launching pad for further process optimization studies, e.g., design of several bioreactor cultivation strategies to further enhance the biopolymer production.

Similar content being viewed by others

References

Reddy, C. S. K., Ghai, R., Rashmi, & Kalia, V. C. (2003). Polyhydroxyalkanoates: an overview. Bioresource Technology, 87, 137–146.

Loo, C. Y., & Sudesh, K. (2007). Polyhydroxyalkanoates: bio-based microbial plastics and their properties. Malaysian Polymer Journal, 2(2), 31–57.

Tokiwa, Y., & Ugwu, C. U. (2007). Biotechnological production of (R)-3-hydroxybutyric acid monomer. Journal of Biotechnology, 132, 264–272.

Van der Walle, G. A. M., de Koning, G. J. M., Weusthuis, R. A., & Eggink, G. (2001). Properties, modification and application of biopolyesters. Advances in Biochemical Engineering/Biotechnology, 71, 263–291.

Chen, G. Q., & Wu, Q. (2005). The applications of polyhydroxyalkanoates as tissue engineering materials. Biomaterials, 26, 6556–6578.

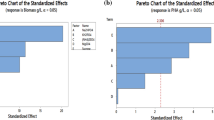

Mokhtari-Hosseini, Z. B., Vasheghani-Farahani, E., Heidarzadeh-Vazifekhoran, A., Shojaodadati, S. A., Karimzadeh, R., & Darani, K. K. (2009). Statistical media optimization for growth and PHB production from methanol by a methylotrophic bacterium. Bioresource Technology, 100, 2436–2443.

Ramadas, N. V., Soccol, C. R., & Pandey, A. (2010). A statistical approach for optimization of polyhydroxybutyrate production by Bacillus sphaericus NCIM 5149 under submerged fermentation using central composite design. Applied Biochemistry and Biotechnology, 162, 996–1007.

Mohamad, S. N., Ramanan, R. N., Mohamad, R., & Ariff, A. B. (2011). Improved mannan-degrading enzymes production by Aspergillus niger through medium optimization. New Biotechnology, 28(2), 146–152.

Berenjian, A., Mahanama, R., Talbot, A., Biffin, R., Regtop, H., Valtchev, P., et al. (2011). Efficient media for high menaquinone-7 production: response surface methodology approach. New Biotechnology, 28, 665–672.

Hrabak, O. (1992). Industrial production of poly-β-hydroxybutyrate. FEMS Microbiology Reviews, 103, 251–256.

Grothe, E., Moo-Young, M., & Chisti, Y. (1999). Fermentation optimization for the production of poly (β-hydroxybutyric acid) microbial thermoplastic. Enzyme and Microbial Technology, 25, 132–141.

Choi, J., & Lee, S. Y. (1999). Factors affecting economics of polyhydroxyalkanoate production by bacterial fermentation. Applied Microbiology and Biotechnology, 51, 13–21.

Grothe, E., & Chisti, Y. (2000). Poly (β-hydroxybutyric acid) thermoplastic production by Alcaligenes latus: behavior of fed-batch cultures. Bioprocess Engineering, 22, 441–449.

Plackett, R. L., & Burman, J. P. (1946). The design of optimum multifactorial experiments. Biometrica, 33, 305–325.

Riis, V., & Mai, W. (1988). Gas chromatographic determination of polyβ-hydroxybutyric acid in microbial biomass after hydrochloric propanolysis. Journal of Chromatography, 445, 285–289.

Miller, G. L. (1959). Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry, 31, 426–428.

Khanna, S., & Srivastava, A. K. (2005). Statistical media optimization studies for growth and PHB production by Ralstonia eutropha. Process Biochemistry, 40, 2173–2182.

Ierusalimsky, N. D. (1967). Bottlenecks in metabolism as growth rate controlling factor. In E. O. Powel, C. G. P. Eans, R. E. Strange, & D. W. Tempest (Eds.), Microbial physiology and continuous culture (pp. 23–33). London: H.M.S.O.

Aiba, S., & Shoda, M. (1969). Reassessment of the product inhibition in alcohol fermentation. Journal of Fermentation Technology, 47, 790–794.

Luong, J. H. T. (1985). Kinetics of ethanol inhibition in alcohol fermentation. Biotechnology and Bioengineering, 27, 280–285.

Launen, L. A., Pinto, L. J., & Moore, M. M. (1999). Optimization of pyrene oxidation by Penicillium janthinellum using response surface methodology. Applied Microbiology and Biotechnology, 51, 510–515.

Rosenbrock, H. H. (1960). An automatic method of finding the greatest or the least value of a function. The Computer Journal, 3, 175–184.

Sayed, E. I., Azhar, A., Abdelhady, H. M., Abdel Hafez, A. M., & Khodair, T. A. (2009). Batch production of polyhydroxybutyrate (PHB) by Ralstonia eutropha and Alcaligenes latus using bioreactor different culture strategies. Journal of Applied Sciences Research, 5, 556–564.

Tanamool, V., Danvirutai, P., Thanonkeo, P., Imai, T., & Kaewkannetra, P. (2009). Production of poly-β-hydroxybutyric acid (PHB) from sweet sorghum juice by Alcaligenes eutrophus TISTR 1095 and Alcaligenes latus ATCC 29714 via batch fermentation. The 3rd International Conference on Fermentation Technology for Value Added Agricultural Products (FerVAAP) 1-6

Acknowledgments

The Senior Research Fellowship (SRF) award by the Department of Biotechnology (DBT), Govt of India, New Delhi to one of the authors (Geeta Gahlawat) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gahlawat, G., Srivastava, A.K. Estimation of Fundamental Kinetic Parameters of Polyhydroxybutyrate Fermentation Process of Azohydromonas australica Using Statistical Approach of Media Optimization. Appl Biochem Biotechnol 168, 1051–1064 (2012). https://doi.org/10.1007/s12010-012-9840-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-012-9840-3