Abstract

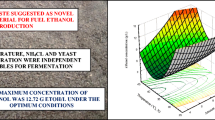

Application of statistical experimental designs for optimization of fermentation parameters to enhance ethanol production, which is an economical and renewable energy source using Saccharomyces cerevisiae NCIM 3090 from palmyra jaggery, was studied in a batch fermentor. Using Plackett–Burman design, impeller speed, concentrations of CoCl2 and KH2PO4 were identified as significant variables, which highly influenced ethanol production, and these variables were further optimized using a central composite design (CCD). The ethanol production was adequately approximated with a full quadratic equation obtained from three factors and five levels of CCD. Maximum ethanol concentration of 132.56 g/l (16.8% [v/v]) was obtained for an impeller speed of 247.179 (≈250) rev/min, CoCl2 of 0.263 g/l and KH2PO4 of 2.39 g/l. A second-order polynomial regression model was fitted and was found adequate with R 2 of 0.8952. This combined statistical approach enables rapid identification and investigation of significant parameters for improving the ethanol production and could be very useful in optimizing processes.

Similar content being viewed by others

References

Sherman, P. D., & Kavasmaneck, P. R. (1978). Ethanol. In G. Grayson (Eds.), Kirk-Othmer Encyclopedia of chemical technology (Vol. 9, 3rd ed., p. 338) New York: Wiley.

Wyman, C. E. (1994). Bioresource Technology, 50, 3–16.

Lynd, L. R., Cushaman, J. H., Nichols, R. J., & Wyman, C. E. (1991). Science, 251, 1318.

Olsson, L., Linden, T., & Hahn-Hagerdal, B. (1992). Applied Biotechnology and Biochemistry, 34/35, 359–367.

Olsson, L., & Hahn-Hagerdal, B. (1993). Process Biochemistry, 28, 249–257.

Heldwein, R., Tromballa, H. W., & Broda, E. (1977). Zeitschrift Für Allgemeine Mikrobiologie, 17(4), 299–308.

Akrida-Demertzi, K., Demertzis, P. G., & Koutinas, A. A. (1988). Biotechnology and Bioengineering 31(7), 666–669.

Veliky, I., & Stefanec, J. (1964). Effect of cobalt on the multiplication of Saccharomyces cerevisiae. Naturwissenschaften, 51(21), 518–519.

Fuhrmann, G. F., & Rothstein, A. (1968). Biochimica et Biophysica Acta, 163(3), 331–338.

Caylak, B., & Vardar Sukan, F. (1998). Turkish Journal Chemistry, 22, 351–359.

Lee, J. M., & Woodward, J. (1983). Biotechnology and Bioengineering, 25, 2441.

Elisson, A., Hofmeyr, J. H. S., Pedler, S., & Hahn-Hagerdal, B. (2001). Enzyme and Microbial Technology, 29, 288–297.

Singh, B., & Satyanarayana, T. (2006). Journal of Applied Microbiology, 101, 344–352.

Plackett, R. L., & Burman, J. P. (1946). Biometrika, 33, 305–325.

Box, G. E. P., & Wilson, K. B. (1951). Journal of Royal Statistical Society (Series B), 13, 1–45.

Cochran, W. G., & Cox, G. M. (1957). Experimental designs (2nd ed., pp. 346–354). New York: Wiley.

Veera Venkata Ratnam, B. (2001). Ph.D. thesis, Andhra University, Visakhapatnam, AP, India.

Francis, F., Sabu, A., Nampoothiri, K. M., Ramachandran, S., Ghosh, S., Szakacs, G., et al. (2003). Biochemical Engineering Journal, 15, 107–115.

Bandaru, V. V. R., Somalanka, S. R., Mendu, D. R., Madicherla, N. R., & Chityala, A. (2006). Enzyme and Microbial Technology, 38, 209–214.

Veera Venkata Ratnam, B., Narasimha Rao, M., Damodara Rao, M., Subba Rao, S., & Ayyanna, C. (2003). World Journal of Microbiology and Biotechnology, 19, 523–526.

Miller, G. L. (1959). Analytical Chemistry, 31, 426–428.

Akhanazarova, S., & Kafarov, V. (1982). Experiment optimization in chemistry and chemical engineering. Moscow: Mir.

Khuri, A. I., & Cornell, J. A. (1987). Response surfaces: Design and analysis. New York: Marcel Dekker.

Box, G. E. P., Hunter, W. G., & Hunter, J. S. (1978). Statistics for experiments. New York: Wiley.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bandaru, V.V.R., Bandaru, S.R., Somalanka, S.R. et al. Optimization of Fermentation Parameters to Enhance the Production of Ethanol from Palmyra Jaggery Using Saccharomyces cerevisiae in a Batch Fermentor. Appl Biochem Biotechnol 143, 224–235 (2007). https://doi.org/10.1007/s12010-007-0048-x

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-007-0048-x