Abstract

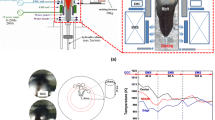

In today’s living environment, employing green, clean, and sustainable energy to produce each kind of product is a necessity. The use of microwaves in the processing of materials has grown more prevalent in recent years. In this research, we theoretically and practically investigate the heating characteristics of a charge (Al-7075 alloy) in a microwave environment since microwave technology has numerous benefits that directly safeguard many factors linked to the environment. Microwave in-house setups at 2.45 GHz and 2.4 kW are used for in-situ charging. In-situ pouring of charge into the mould cavity is done for 15 min at melting temperature. The COMSOL Multiphysics 5.6 version is used to model and heat the charge using the finite element approach. With a maximum inaccuracy of 7.24%, the simulated heating curve for 15 min of microwave exposure agreed well with the actual heating curve of charge in the time temperature plot. Al-7075 alloys were characterized both in their as-received and as-cast states. Corrosion resistance qualities of the as-cast Al-7075 alloy was found to be superior to those of the as-received alloy, with a microhardness value that was 8% higher.

Similar content being viewed by others

Data availability

The datasets generated during and/or analysed during the current study are available within the article.

References

Mishra, R.R., Sharma, A.K.: On melting characteristics of bulk Al-7039 alloy during in-situ microwave casting. Appl. Therm. Eng. 111, 660–675 (2017)

Singh, S., Gupta, D., Jain, V.: Novel microwave composite casting process: Theory, feasibility and characterization. Mater. Design. 111, 51–59 (2016)

Adin, M.: Performances of cryo-treated and untreated cutting tools in machining of AA7075 aerospace aluminium alloy. Eur. Mech. Sci. 7(2), 70–81 (2023)

Bhoi, N.K., Singh, H., Pratap, S.: Developments in the aluminum metal matrix composites reinforced by micro/nano particles – A review. J. Compos. Mater. 54(6), 813–833 (2019)

Bhoi, N.K., Singh, H.: Evaluation of susceptor-assisted microwave-sintering-produced Al-Y2O3 composite material’s compression and reciprocating wear performance. Phys. Scr. 98(10) (2023)

Bhoi, N.K., Singh, H., Pratap, S., Jain, P.K.: Aluminum Yttrium Oxide Metal Matrix Composite synthesized by microwave hybrid sintering: Processing, microstructure and mechanical response. J. Inorg. Organomet. Polym Mater. 32(4), 1319–1333 (2022)

Kumar Bhoi, N., Singh, H., Pratap, S.: Synthesis and characterization of zinc oxide reinforced aluminum metal matrix composite produced by microwave sintering. J. Compos. Mater. 54(24), 3625–3636 (2020)

Bhoi, N.K., Singh, H., Pratap, S.: Futuristic synthesis strategies for aluminum-based metal-matrix composites. Compos. Mater. pp. 3–23. (2021)

Bhoi, N.K., Singh, H., Pratap, S., Gupta, M., Jain, P.K.: Investigation on the combined effect of ZnO nanorods and Y2O3 nanoparticles on the microstructural and mechanical response of aluminium. Adv. Compos. Mater. 31(3), 289–310 (2021)

Kumar, A., Bhoi, N.K., Singh, H.: Corrosion Behavior of Microwave Clad Material Under Different Acidic Environment, Manufacturing Engineering2020, pp. 603–612

Singh, S., Gupta, D., Jain, V.: Processing of Ni-WC-8Co MMC casting through microwave melting. Mater. Manuf. Processes. 33(1), 26–34 (2018)

Xu, L., Srinivasakannan, C., Peng, J., Guo, S., Xia, H.: Study on characteristics of microwave melting of copper powder. J. Alloys Compd. 701, 236–243 (2017)

Lingappa, M.S., Srinath, M., Amarendra, H.: Microwaves: A source of energy for melting of bulk zinc. Mater. Today: Proc. 5(2), 7782–7787 (2018)

Gangwar, V., Singh, H., Kumar, S.: Influence of process parameter on microstructure, residual stress, microhardness and porosity of AA-6063 microwave cast. Int. J. Metalcast. 16(2), 826–841 (2022)

Kaushal, S., Bohra, S., Gupta, D., Jain, V.: On processing and characterization of Cu–Mo-based castings through microwave heating. Int. J. Metalcast. 15, 530–537 (2021)

Bhatt, S., Ghetiya, N., Joshi, M.: Multiphysics simulation and validation of microwave melting characteristics of AA6061 by finite element analysis. Adv. Mater. Process. Technol. 8(sup3), 1557–1568 (2022)

Patel, D.K., Bhoi, N.K., Singh, H.: Microwave heating capabilities of different susceptor material: Experimental and Simulation Study. Silicon. 14(12), 6621–6635 (2021)

Sahu, A.K., Mahapatra, S.S., Bhoi, N.K., Singh, H., Leite, M., Goel, S.: Experimental Investigation on Microwave Sintered Composite Tool for Electro-Discharge Machining of Titanium Alloy. J. Mater. Eng. Perform. 31(6), 5026–5041 (2022)

Bhoi, N.K., Patel, D.K., Singh, H., Pratap, S., Jain, P.K.: Multi-physics simulation study of microwave hybrid sintering of aluminium and mechanical characteristics. Proc. Institution Mech. Eng. Part. E: J. Process. Mech. Eng. 236(5), 1779–1789 (2022)

Kumar Bhoi, N., Singh, H., Pratap, S., Naher, S., Jain, P.K.: Zinc oxide nanorods effect in micro structural and mechanical characteristics of aluminium composite material. Mater. Sci. Engineering: B 278 (2022)

Gupta, M., Leong, E.W.W.: Microwaves and metals, Wiley (2008)

Singh, B., Zafar, S.: Understanding temperature characteristics during microwave cladding through process modeling and experimental investigation. CIRP J. Manufact. Sci. Technol. 37, 401–413 (2022)

Zhu, J., Yi, L., Yang, Z., Duan, M.: Three-dimensional numerical simulation on the thermal response of oil shale subjected to microwave heating. Chem. Eng. J. 407, 127197 (2021)

Bhoi, N.K., Singh, H., Pratap, S., Jain, P.K.: Microwave material processing: a clean, green, and sustainable approach, Sustainable Engineering Products and Manufacturing Technologies2019, pp. 3–23

Neeraj Kumar, H.S., Bhoi, S., Pratap: A study on microwave susceptor material for hybrid heating, Journal of Physics: Conference Series 1240 012097. (2019)

Singh, H., Jain, P.K., Bhoi, N., Pratap, S.: Experimental study pertaining to microwave sintering (MWS) of Al-Metal Matrix Composite - A Review. Mater. Sci. Forum. 928, 150–155 (2018)

Arora, G., Pathak, H., Zafar, S.: Fabrication and characterization of microwave cured high-density polyethylene/carbon nanotube and polypropylene/carbon nanotube composites. J. Compos. Mater. 53(15), 2091–2104 (2019)

Acknowledgements

The author(s) would like to acknowledge Microwave Material Processing Research Laboratory of PDPM IIITDM Jabalpur for the fabrication and characterizations of the material.

Funding

The institute research grant IIITDMJ/ODRSPC/2017/2 and funding from the Science and Engineering Research Board Government of India (Grant No.-DST/SRG/2019/000571 and DST/CRG/2022/006481) provided significant financial support for this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent for publication

All the authors have approved the final manuscript before submission.

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Meti, A., Bhoi, N.K. & Singh, H. Microwave-enhanced In-Situ casting of Al-7075 Alloy: a comprehensive experimental and numerical investigation. Int J Interact Des Manuf (2024). https://doi.org/10.1007/s12008-024-01897-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-024-01897-w