Abstract

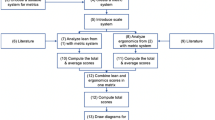

In manufacturing organizations, digitization and sustainability significantly impact how digital and green features are integrated into physical products and services. This study looks at how these two ideas come together in traditional manufacturing. Making things smart and eco-friendly is important for growing factories and has begun to evolve. However, due to the most significant barriers, it is challenging for manufacturing industries to embrace smart, sustainable solutions. In the past, researchers looked at what's stopping factories from being sustainable and using new technology. A comprehensive literature review identified 33 barriers and 31 solutions under eight smart, sustainable manufacturing (SSM) categories. The fuzzy AHP approach prioritized these barriers, with technology barriers ranking highest. Stochastic fuzzy EDAS assessed and ranked SSM solutions, highlighting the most effective collaborative efforts in environmental awareness (S10) and training on smart and sustainable processes (S2). This study also addresses economic, social, and environmental stakeholder issues. A sensitivity analysis is also performed to examine the validity of the current study’s results. The results of this research may assist decision-makers and professionals in defining the main barriers and implementing solutions for the effective adoption of smart sustainability practices throughout the industrial sector. This paper is just the beginning, and there's more to learn.

Similar content being viewed by others

References

Nallusamy, S., Saravanan, V.: Optimization of process flow in an assembly line of manufacturing unit through lean tools execution. Int. J. Eng. Res. Africa 38, 133–143 (2018). https://doi.org/10.4028/www.scientific.net/JERA.38.133

Hemalatha, C., Sankaranarayanasamy, K., Durairaaj, N.: Lean and agile manufacturing for work-in-process (WIP) control. Mater. Today Proc. (2021). https://doi.org/10.1016/j.matpr.2020.12.473

Fahmideh, M., Beydoun, G.: Big data analytics architecture design—An application in manufacturing systems. Comput. Ind. Eng. 128, 948–963 (2019). https://doi.org/10.1016/j.cie.2018.08.004

Ramadan, M., Al-maimani, H., Noche, B.: RFID-enabled smart real-time manufacturing cost tracking system. Int. J. Adv. Manuf. Technol. (2016). https://doi.org/10.1007/s00170-016-9131-1

Cheng, Y., Tao, F., Zhao, D., Zhang, L.: Robotics and Computer-Integrated Manufacturing Modeling of manufacturing service supply – demand matching hypernetwork in service-oriented manufacturing systems. Robot. Comput. Integr. Manuf. 45, 59–72 (2017). https://doi.org/10.1016/j.rcim.2016.05.007

Baldassarre, F., Ricciardi, F.: The additive manufacturing in the industry 40 Era: The case of an Italian FabLab. J. Emerg. Trends Market Manag. I(1), 105–115 (2017)

Mao, S., Wang, B., Tang, Y., Qian, F.: Opportunities and challenges of artificial intelligence for green manufacturing in the process industry. Engineering 5(6), 995–1002 (2019). https://doi.org/10.1016/j.eng.2019.08.013

Li, Y., Gao, M., Yang, L., Zhang, C., Zhang, B., Zhao, X.: Design of and research on industrial measuring devices based on Internet of Things technology. Ad Hoc Netw. 102, 102072 (2020). https://doi.org/10.1016/j.adhoc.2020.102072

Kusiak, A.: Smart manufacturing. Int. J. Prod. Res. 56(1–2), 508–517 (2018). https://doi.org/10.1080/00207543.2017.1351644

Malek, J., Desai, T.N.: A systematic literature review to map literature focus of sustainable manufacturing. J. Clean. Prod. 256, 120345 (2020). https://doi.org/10.1016/j.jclepro.2020.120345

Zhang, H., Veltri, A., Calvo-Amodio, J., Haapala, K.R.: Making the business case for sustainable manufacturing in small and medium-sized manufacturing enterprises: a systems decision making approach. J Clean Prod (2020). https://doi.org/10.1016/j.jclepro.2020.125038

Cioffi, R., Travaglioni, M., Piscitelli, G., Petrillo, A., Parmentola, A.: Smart manufacturing systems and applied industrial technologies for a sustainable industry: a systematic literature review. Appl. Sci. (2020). https://doi.org/10.3390/APP10082897

Maghazei, O., Netland, T.: Drones in manufacturing: exploring opportunities for research and practice. J. Manuf. Technol. Manag. 31(6), 1237–1259 (2020). https://doi.org/10.1108/JMTM-03-2019-0099

Wawrla, L., Maghazei, O., Netland, P. D. T.: Applications of drones in warehouse operations” ETH Zurich, no. August, p. 13

Wegner, A., Graham, J., Ribble, E.: A New Approach to Cyberphysical Security in Industry 4.0. Springer, Berlin, pp. 59–72 (2017)

Prinsloo, J., Sinha, S., von Solms, B.: A review of industry 4.0 manufacturing process security risks. Appl. Sci. (2019). https://doi.org/10.3390/app9235105

Beier, G., Ullrich, A., Niehoff, S., Reibig, M., Habich, M.: Industry 4.0: how it is defined from a sociotechnical perspective and how much sustainability it includes—a literature review. J. Clean Prod. (2020). https://doi.org/10.1016/j.jclepro.2020.120856

Ervural, B.C., Ervural, B.: Overview of cyber security in the industry 4.0 Era, pp. 267–284. Springer, Cham (2018)

Moghaddam, M., Cadavid, M.N., Kenley, C.R., Deshmukh, A.V.: Reference architectures for smart manufacturing: a critical review. J. Manuf. Syst. 49(June), 215–225 (2018). https://doi.org/10.1016/j.jmsy.2018.10.006

Agarwal, S., et al.: Prioritizing the barriers of green smart manufacturing using AHP in implementing Industry 4.0: a case from Indian automotive industry. TQM J (2022). https://doi.org/10.1108/TQM-07-2022-0229

Kumar, P., Brar, P.S., Singh, D., Bhamu, J.: Fuzzy AHP approach for barriers to implement LSS in the context of Industry 4.0. Int. J. Product. Perform. Manag. (2020). https://doi.org/10.1108/IJPPM-12-2021-0715

Dutta, G., Kumar, R., Sindhwani, R., Singh, R.K.: Overcoming the barriers of effective implementation of manufacturing execution system in pursuit of smart manufacturing in SMEs. Procedia Comput. Sci. 200(January), 820–832 (2022). https://doi.org/10.1016/j.procs.2022.01.279

Malek, J., Desai, T.N.: A framework for prioritizing the solutions to overcome sustainable manufacturing barriers. Clean. Logist. Supply Chain 1(July), 100004 (2021). https://doi.org/10.1016/j.clscn.2021.100004

Yip, W.S., To, S.: Identification of stakeholder related barriers in sustainable manufacturing using Social Network Analysis. Sustain. Prod. Consum. 27, 1903–1917 (2021). https://doi.org/10.1016/j.spc.2021.04.018

Kumar, P., Bhamu, J., Sangwan, K.S.: Analysis of barriers to industry 4.0 adoption in manufacturing organizations: an ISM approach. Procedia CIRP 98(March), 85–90 (2021). https://doi.org/10.1016/j.procir.2021.01.010

Wong, L.W., Tan, G.W.H., Lee, V.H., Ooi, K.B., Sohal, A.: Psychological and system-related barriers to adopting blockchain for operations management: an artificial neural network approach. IEEE Trans. Eng. Manag. (2021). https://doi.org/10.1109/TEM.2021.3053359

Virmani, N., Bera, S., Kumar, R.: Identification and testing of barriers to sustainable manufacturing in the automobile industry: a focus on Indian MSMEs. Benchmarking 28(3), 857–880 (2021). https://doi.org/10.1108/BIJ-08-2020-0413

Stentoft, J., AdsbøllWickstrøm, K., Philipsen, K., Haug, A.: Drivers and barriers for Industry 4.0 readiness and practice: empirical evidence from small and medium-sized manufacturers. Prod Plan Control 32(10), 811–828 (2021). https://doi.org/10.1080/09537287.2020.1768318

Majumdar, A., Garg, H., Jain, R.: Managing the barriers of Industry 4.0 adoption and implementation in textile and clothing industry: Interpretive structural model and triple helix framework. Comput Ind 125, 103372 (2021). https://doi.org/10.1016/j.compind.2020.103372

Chauhan, C., Singh, A., Luthra, S.: Barriers to industry 4.0 adoption and its performance implications: an empirical investigation of emerging economy. J. Clean. Prod. 285, 124809 (2021). https://doi.org/10.1016/j.jclepro.2020.124809

Singh, R., Bhanot, N.: An integrated DEMATEL-MMDE-ISM based approach for analysing the barriers of IoT implementation in the manufacturing industry. Int. J. Prod. Res. 58(8), 2454–2476 (2020). https://doi.org/10.1080/00207543.2019.1675915

Raj, A., Dwivedi, G., Sharma, A., de Sousa-Jabbour, A.B.L., Rajak, S.: Barriers to the adoption of industry 4.0 technologies in the manufacturing sector: an inter-country comparative perspective. Int. J. Prod. Econ. (2020). https://doi.org/10.1016/j.ijpe.2019.107546

Singh, M., Singh, K., Sethi, A.: An empirical investigation and prioritizing critical barriers of green manufacturing implementation practices through VIKOR approach. World J. Sci. Technol. Sustain. Dev. 17(2), 235–254 (2020). https://doi.org/10.1108/wjstsd-08-2019-0060

Ariffin, R., et al.: Drivers and barriers analysis for green manufacturing practices in Malaysian SMEs: a preliminary findings. Procedia CIRP 26, 658–663 (2020). https://doi.org/10.1016/j.procir.2015.02.085

Narayanan, A.E., Sridharan, R., Ram Kumar, P.N.: Analyzing the interactions among barriers of sustainable supply chain management practices: a case study. J. Manuf. Technol. Manag. 30(6), 937–971 (2019). https://doi.org/10.1108/JMTM-06-2017-0114

Sindhwani, R., Mittal, V.K., Singh, P.L., Aggarwal, A., Gautam, N.: Modelling and analysis of barriers affecting the implementation of lean green agile manufacturing system (LGAMS). Benchmarking 26(2), 498–529 (2019). https://doi.org/10.1108/BIJ-09-2017-0245

Rauch, E., Dallasega, P., Unterhofer, M.: Requirements and barriers for introducing smart manufacturing in small and medium-sized enterprises. IEEE Eng. Manag. Rev. 47(3), 87–94 (2019). https://doi.org/10.1109/EMR.2019.2931564

Bhandari, D., Singh, R.K., Garg, S.K.: Prioritisation and evaluation of barriers intensity for implementation of cleaner technologies: framework for sustainable production. Resour. Conserv. Recycl. 146(February), 156–167 (2019). https://doi.org/10.1016/j.resconrec.2019.02.038

Klein, M.M., Biehl, S.S., Friedli, T.: Barriers to smart services for manufacturing companies – an exploratory study in the capital goods industry. J. Bus. Ind. Mark. 33(6), 846–856 (2018). https://doi.org/10.1108/JBIM-10-2015-0204

Raut, R., Narkhede, B.E., Gardas, B.B., Luong, H.T.: An ISM approach for the barrier analysis in implementing sustainable practices: the Indian oil and gas sector. Benchmarking 25(4), 1245–1271 (2018). https://doi.org/10.1108/BIJ-05-2016-0073

Gupta, H., Barua, M.K.: A framework to overcome barriers to green innovation in SMEs using BWM and Fuzzy TOPSIS. Sci. Total. Environ. 633, 122–139 (2018). https://doi.org/10.1016/j.scitotenv.2018.03.173

Kumar, A., Dixit, G.: An analysis of barriers affecting the implementation of e-waste management practices in India: a novel ISM-DEMATEL approach. Sustain. Prod. Consum. 14, 36–52 (2018). https://doi.org/10.1016/j.spc.2018.01.002

Bhanot, N., Rao, P.V., Deshmukh, S.G.: An integrated approach for analysing the enablers and barriers of sustainable manufacturing. J. Clean. Prod. 142, 4412–4439 (2017). https://doi.org/10.1016/j.jclepro.2016.11.123

Mittal, V.K., Sangwan, K.S.: Prioritizing barriers to green manufacturing: environmental, social and economic perspectives. Procedia CIRP 17, 559–564 (2014). https://doi.org/10.1016/j.procir.2014.01.075

Ghorabaee, M.K., Zavadskas, E.K., Olfat, L., Turskis, Z.: Multi-criteria inventory classification using a new method of evaluation based on distance from average solution (EDAS). Inform 26(3), 435–451 (2015). https://doi.org/10.15388/Informatica.2015.57

Emovon, I., Norman, R.A., Murphy, A.J.: Hybrid MCDM based methodology for selecting the optimum maintenance strategy for ship machinery systems. J. Intell. Manuf. 29(3), 519–531 (2018). https://doi.org/10.1007/s10845-015-1133-6

Mathew, M., Chakrabortty, R.K., Ryan, M.J.: A novel approach integrating AHP and TOPSIS under spherical fuzzy sets for advanced manufacturing system selection. Eng. Appl. Artif. Intell. 96(June), 103988 (2020). https://doi.org/10.1016/j.engappai.2020.103988

Mathew, M., Chakrabortty, R.K., Ryan, M.J.: Selection of an optimal maintenance strategy under uncertain conditions: an interval type-2 fuzzy AHP-TOPSIS method. IEEE Trans. Eng. Manag. (2020). https://doi.org/10.1109/tem.2020.2977141

Kahraman, C., KeshavarzGhorabaee, M., Zavadskas, E.K., CevikOnar, S., Yazdani, M., Oztaysi, B.: Intuitionistic fuzzy EDAS method: an application to solid waste disposal site selection. J. Environ. Eng. Landsc. Manag. 25(1), 1–12 (2017). https://doi.org/10.3846/16486897.2017.1281139

Ju, Y., et al.: A new framework for health-care waste disposal alternative selection under multi-granular linguistic distribution assessment environment. Comput. Ind. Eng. 145(May), 106489 (2020). https://doi.org/10.1016/j.cie.2020.106489

Li, X., Ju, Y., Ju, D., Zhang, W., Dong, P., Wang, A.: Multi-attribute group decision making method based on EDAS under picture fuzzy environment. IEEE Access 7, 141179–141192 (2019). https://doi.org/10.1109/ACCESS.2019.2943348

Hou, H., Zhao, C.: A novel D-SCRI–EDAS method and its application to the evaluation of an online live course platform. Systems (2022). https://doi.org/10.3390/systems10050157

Zhu, Y.J., Guo, W., Liu, H.C.: Knowledge representation and reasoning with an extended dynamic uncertain causality graph under the pythagorean uncertain linguistic environment. Appl. Sci. (2022). https://doi.org/10.3390/app12094670

Chini, M., Arefi, S.L., Zolfani, S.H., Ustinovicius, L.: Choosing a proper method for strengthening WPC beams with grooving method using swara-edas. Arch. Civ. Eng. 64(4), 161–174 (2018). https://doi.org/10.2478/ace-2018-0050

Lin, C.T., Chiang, C.Y.: Development of strategies for Taiwan’s corrugated box precision printing machine industry—an implementation for SWOT and EDAS methods. Sustainability (2022). https://doi.org/10.3390/su14095144

Abubakr, M., Abbas, A.T., Tomaz, I., Soliman, M.S., Luqman, M., Hegab, H.: Sustainable and smart manufacturing: an integrated approach. Sustain. 12(6), 1–19 (2020). https://doi.org/10.3390/su12062280

Moldavska, A., Welo, T.: The concept of sustainable manufacturing and its definitions: a content-analysis based literature review. J. Clean. Prod. 166, 744–755 (2017). https://doi.org/10.1016/j.jclepro.2017.08.006

Singh, P.K., Sarkar, P.: A framework based on fuzzy AHP-TOPSIS for prioritizing solutions to overcome the barriers in the implementation of ecodesign practices in SMEs. Int. J. Sustain. Dev. World Ecol. 26(6), 506–521 (2019). https://doi.org/10.1080/13504509.2019.1605547

Dubois, A., Gadde, L.E.: ‘Systematic combining’-a decade later. J. Bus. Res. 67(6), 1277–1284 (2014). https://doi.org/10.1016/j.jbusres.2013.03.036

Rao, P. K., Bhargav, V. R.: A study on green packaging- a case study approach with reference to dell Inc. No. July, pp. 83–84, (2016)

Çinar, Z.M., Nuhu, A.A., Zeeshan, Q., Korhan, O., Asmael, M., Safaei, B.: Machine learning in predictive maintenance towards sustainable smart manufacturing in industry 4.0. Sustainability (2020). https://doi.org/10.3390/su12198211

Andreadis, E., Garza-Reyes, J.A., Kumar, V.: Towards a conceptual framework for value stream mapping (VSM) implementation: an investigation of managerial factors. Int. J. Prod. Res. 55(23), 7073–7095 (2017). https://doi.org/10.1080/00207543.2017.1347302

Arey, D., Le, C.H., Gao, J.: Lean industry 4.0: a digital value stream approach to process improvement. Procedia Manuf. 54, 19–24 (2020). https://doi.org/10.1016/j.promfg.2021.07.004

Vrchota, J., Pech, M., Rolínek, L., Bednář, J.: Sustainability outcomes of green processes in relation to industry 4.0 in manufacturing: systematic review. Sustainability (2020). https://doi.org/10.3390/su12155968

Mazurek, J., Mielcová, E.: The evaluation of economic recession magnitude: introduction and application. Prague Econ. Pap. 2, 182–205 (2013). https://doi.org/10.18267/j.pep.447

Song, M., Wang, S., Zhang, H.: Could environmental regulation and R & D tax incentives affect green product innovation ? J. Clean. Prod. 258, 120849 (2020). https://doi.org/10.1016/j.jclepro.2020.120849

Nižetić, S., Šolić, P., López-de-Ipiña González-de-Artaza, D., Patrono, L.: Internet of Things (IoT): opportunities, issues and challenges towards a smart and sustainable future. J. Clean. Prod. (2020). https://doi.org/10.1016/j.jclepro.2020.122877

Manavalan, E., Jayakrishna, K.: A review of Internet of Things (IoT) embedded sustainable supply chain for industry 40 requirements. Comput. Ind. Eng. 127, 925–953 (2019). https://doi.org/10.1016/j.cie.2018.11.030

Balaji, V., Venkumar, P., Sabitha, M. S., Amuthaguka, D.: DVSMS: dynamic value stream mapping solution by applying IIoT. Sadhana - Acad. Proc. Eng. Sci., (2020) https://doi.org/10.1007/s12046-019-1251-5

Jena, M.C., Mishra, S.K., Moharana, H.S.: Application of Industry 4.0 to enhance sustainable manufacturing. Environ. Prog. Sustain. Energy 39(1), 1–11 (2020). https://doi.org/10.1002/ep.13360

Machado, C.G., Winroth, M.P., Ribeiro da Silva, E.H.D.: Sustainable manufacturing in Industry 4.0: an emerging research agenda. Int. J. Prod. Res. 58(5), 1462–1484 (2020). https://doi.org/10.1080/00207543.2019.1652777

Teodorico, C., Carmina, S., Anastasia, S., Roberto, G., Francesco, T., Maria, R.: Noise and cardiovascular effects in workers of the sanitary fixtures industry. Int. J. Hyg. Environ. Health (2014). https://doi.org/10.1016/j.ijheh.2014.09.007

Awan, U., Arnold, M.G., Gölgeci, I.: Enhancing green product and process innovation: towards an integrative framework of knowledge acquisition and environmental investment. Bus. Strateg. Environ. 30(2), 1283–1295 (2021). https://doi.org/10.1002/bse.2684

Song, M., Wang, S., Sun, J.: Environmental regulations, staff quality, green technology, R&D efficiency, and profit in manufacturing. Technol. Forecast. Soc. Change 133(March), 1–14 (2018). https://doi.org/10.1016/j.techfore.2018.04.020

Ahmad, S., Yew, K., Lang, M., Peng, W.: Resources, conservation & recycling sustainable product design and development : a review of tools, applications and research prospects. Resour. Conserv. Recycl. 132(January), 49–61 (2018). https://doi.org/10.1016/j.resconrec.2018.01.020

Ahmad, S., Ahmad, S.: Green human resource management: policies and practices. Cogent Bus. Manag. (2015). https://doi.org/10.1080/23311975.2015.1030817

Yousefnezhad, N., Malhi, A., Främling, K.: Security in product lifecycle of IoT devices: a survey. J. Netw. Comput. Appl. 171(June), 102779 (2020). https://doi.org/10.1016/j.jnca.2020.102779

Saura, J.R., Ribeiro-Soriano, D., Palacios-Marqués, D.: Evaluating security and privacy issues of social networks based information systems in Industry 4.0. Enterp. Inf. Syst. 00(00), 1–17 (2021). https://doi.org/10.1080/17517575.2021.1913765

Jamai, I., Ben Azzouz, L., Saidane, L. A.: Security issues in Industry 4.0,” 2020 Int. Wirel. Commun. Mob. Comput. IWCMC 2020, vol. 0, pp. 481–488, 2020, https://doi.org/10.1109/IWCMC48107.2020.9148447.

Olabanji, O. M., Mpofu, K.: Appraisal of conceptual designs: coalescing fuzzy analytic hierarchy process (F-AHP) and Fuzzy Grey Relational Analysis (F-GRA). Elsevier B.V., 2020. https://doi.org/10.1016/j.rineng.2020.100194.

Gegovska, T., Koker, R., Cakar, T.: Green supplier selection using fuzzy multiple-criteria decision-making methods and artificial neural networks. Comput. Intell. Neurosci. (2020). https://doi.org/10.1155/2020/8811834

Buckley, J.J.: Fuzzy hierarchical analysis. Fuzzy Sets Syst. 17(3), 233–247 (1985). https://doi.org/10.1016/0165-0114(85)90090-9

Ilieva, G., Yankova, T., Klisarova-Belcheva, S.: Decision analysis with classic and fuzzy EDAS modifications. Comput. Appl. Math. 37(5), 5650–5680 (2018). https://doi.org/10.1007/s40314-018-0652-0

Lai, I.K.W., Shi, G.: The impact of privacy concerns on the intention for continued use of an integrated mobile instant messaging and social network platform. Int. J. Mob. Commun. 13(6), 641–669 (2015). https://doi.org/10.1504/IJMC.2015.072086

Flatt, H., Schriegel, S., Jasperneite, J., Trsek, H., Adamczyk, H.: Analysis of the Cyber-Security of industry 4.0 technologies based on RAMI 4.0 and identification of requirements. IEEE Int. Conf. Emerg. Technol. Fact. Autom. ETFA, vol. 2016-Novem, (2016), https://doi.org/10.1109/ETFA.2016.7733634.

Punia Sindhu, S., Nehra, V., Luthra, S.: Recognition and prioritization of challenges in growth of solar energy using analytical hierarchy process: Indian outlook. Energy 100, 332–348 (2016). https://doi.org/10.1016/j.energy.2016.01.091

Pathak, S.K., Sharma, V., Chougule, S.S., Goel, V.: Prioritization of barriers to the development of renewable energy technologies in India using integrated Modified Delphi and AHP method. Sustain. Energy Technol. Assessments 50(November), 101818 (2020). https://doi.org/10.1016/j.seta.2021.101818

Sandu, N., Gide E.: A model for successful adoption of cloud-based services in Indian SMEs. In: Proc. - 2019 Int. Conf. Futur. Internet Things Cloud, FiCloud 2019, pp. 169–174, 2019, https://doi.org/10.1109/FiCloud.2019.00031.

Silva, S., Nuzum, A.K., Schaltegger, S.: Stakeholder expectations on sustainability performance measurement and assessment. a systematic literature review. J. Clean. Prod. 217, 204–215 (2019). https://doi.org/10.1016/j.jclepro.2019.01.203

Funding

No funding information available.

Author information

Authors and Affiliations

Contributions

Conceptualization: Amber Batwara · Vikram Sharma · Mohit Makkar. Methodology: Amber Batwara. Writing: Amber Batwara. Supervision: Vikram Sharma · Mohit Makkar.

Corresponding author

Ethics declarations

Conflict of interest

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial or non-financial interest in the subject matter or materials discussed in this manuscript. The authors have no financial or proprietary interests in any material discussed in this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Batwara, A., Sharma, V. & Makkar, M. Prioritization of the approaches for overcoming smart sustainable manufacturing barriers using stochastic fuzzy EDAS method. Int J Interact Des Manuf (2024). https://doi.org/10.1007/s12008-024-01891-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-024-01891-2