Abstract

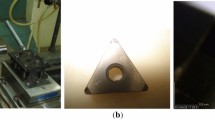

Cryogenic treatment is the technique of exposing tools/workpieces to cryogenic temperatures to eliminate residual stresses and improve tool performance under specified applications. The current study investigated the impact of cryogenic treatment and coating on cutting tool performance when machining (CNC turning) EN24 steel. The WC grade K20 inserts were obtained and cryogenically treated in a controlled environment for 24 h at 193 °C. Taguchi’s L16 orthogonal array was used in the studies. Turning experiments were carried out under dry-cutting circumstances with three cutting speeds (200, 350, and 500 m/min), three feed rates (0.2, 0.3, and 0.4 mm/rev), and various edge rounds (50 and 80 microns). The machined workpiece’s cutting force and surface roughness were used to assess the machining performance of cryogenically treated and untreated inserts. Inserts that had been cryogenically treated had lower cutting force and surface roughness than untreated inserts. With cryogenically treated coated carbide inserts with a 50-micron edge rounding, the decreased cutting force and surface roughness were determined to be around 1650 N and 0.534 μm, respectively, when cutting EN24 alloy steel at a cutting speed of 500 m/min and a feed rate of 0.2 mm/revolution. Furthermore, the microhardness of the cryo-treated inserts was improved. The integration of cryogenic treatment and coating techniques, resulting in enhanced tool performance and reduced environmental impact, reflects a paradigm shift in machining processes.

Similar content being viewed by others

Data availability

The data that support the findings are included within the manuscript itself.

References

Gurumurthy, B.M., Hindi, J., Hegde, A., Sharma, S., Kini, A.: Effect of machining parameters on tool life and surface roughness of aisi 1040 dual phase steel. Mat. Res. 25 (2022)

Asha, P.B., Rao, P., Kiran, C.R., Ravi Kumar, R.: D. V.: Effect of machining parameters on cutting tool temperature and tool life while turning EN24 and HcHCr grade alloy steel. Mater. Today Proc. 5(5), 2, 11819–11826 (2018)

Manikandan Chinnachamy, R., Balakrishnan: Experimental investigation on machining characteristics of EN24 alloy steel using desirability approach. Mater. Today Proc. 65(8), 3581–3589 (2022)

Andrews, A.E., Jensin Joshua, A., Ravikumar Solomon, J.G., Gokul, B., Srinath, K.: Optimizing machining parameters of carbon steel EN24 to minimize surface roughness and tool wear. Mater. Today Proc. 33(7), 3902–3906 (2020)

Gundarneeya, T.P., Golakiya, V.D., Ambaliya, S.D., Patel, S.H.: Experimental investigation of process parameters on surface roughness and dimensional accuracy in hard turning of EN24 steel. Mater. Today Proc. 57(2), 674–680 (2022)

Parida, A.K., Maity, K.: Experimental investigation on tool life and chip morphology in hot machining of monel-400. Eng. Sci. Techno. 21, 371–370 (2018)

Gupta, M.K., Niesłony, P., Korkmaz, M.E., Kuntoglu, M., Krolczyk, G.M., Gunay, M., Sarikaya, M.: Comparison of Tool wear, Surface morphology, specific cutting energy and cutting temperature in machining of Titanium alloys under Hybrid and Green cooling strategies. Int. J. Prec Eng. Manuf. -Green Tech. (2023)

Tian, C., Zhou, G., Zhang, J., Zhang, C.: Optimization of cutting parameters considering tool wear conditions in low-carbon manufacturing environment. J. Clean. Prod. 226, 706–719 (2019)

Moganapriya Chinnasamy, R., Rathanasamy, S.K., Pal, Sathish Kumar Palaniappan: Effectiveness of cryogenic treatment on cutting tool inserts: A review. Int. J. Ref. Met. Hard Mat. 108, 105946 (2022)

Kumar, A., Bala, N., Dhami, S.S., Kumar, S.: Effects of cryogenic treatment on the performance of coated tungsten carbide inserts during milling of EN24 steel. Mat. Today Proc. (2023)

Nursel Altan Ozbek: Effects of cryogenic treatment types on the performance of coated tungsten tools in the turning of AISI H11 steel. J. Mat. Res. Tech. 9(4), 9442–9456 (2020)

Balamurugan Karnan, A., Kuppusamy, T.P., Latchoumi, A., Banerjee, A., Sinha, A., Biswas: Ananda Kumar Subramanian: Multi-response optimization of turning parameters for cryogenically treated and tempered WC–Co inserts. J. Inst. Eng. : Ser. D. 103, 263–274 (2022)

Satish Kumar, Nitin, K., Khedkar, B., Jagtap, Singh, T.P.: The effects of cryogenic treatment on cutting tools. IOP Conf. Ser. Mat. Sci. Eng. 225, 012104 (2017)

Soler, D., Aristimuno, P.X., Garay, A., Arrazola, P.J., Klocke, F., Veselovac, D., Seimann, M.: Finding correlations between tool life and fundamental dry cutting tests in finishing turning of steel. Proc. Eng. 132, 615–623 (2015)

Abhang, L.B., Hameedullah, M.: Parametric investigation of turning process on EN-31 steel. Proce Mater. Sci. 6, 1516–1523 (2014)

Nexhat Qehaja, K., Jakupi, A., Bunjaku, M., Bruci, H., Osmani: Effect of machining parameters and machining time on surface roughness in dry turning process. Proce Eng. 100, 135–140 (2015)

Saketi, S., Ostby, J., Olsson, M.: Influence of tool surface topography on the material transfer tendency and tool wear in the turning of 316L stainless steel. Wear. 368–369, 239–252 (2016)

Satish Chinchanikar, Choudhury, S.K.: Effect of work material hardness and cutting parameters on performance of coated carbide tool when turning hardened steel: An optimization approach. Measurement. 46, 1572–1584 (2013)

Adel, T., Abbas, Magdy, M.E., Rayes, A.A., Al-Abduljabbar, A.E., Ragab: Faycal Benyahia, Ahmed Elkaseer: Effects of tool edge geometry and cutting conditions on the performance indicators in dry turning AISI 1045 steel. Machines. 11(3), 397 (2023)

Zhao, T., Zhou, J.M., Bushlya, V., Stahl, J.E.: Effect of cutting edge radius on surface roughness and tool wear in hard turning of AISI 52100 steel. Int. J. Adv. Manuf. Technol. 91, 3611–3618 (2017)

Das, A., Das, S.R., Patel, S.K.: Bibhuti Bhusan Biswal: Experimental investigation of various machining attributes and cost estimation during machining of hardened AISI 4340 steel with untreated and cryo treated cermet inserts. Mech. Ind. 21, 110 (2020)

Kumar, A., Kumar, A., Kumar, A., Gupta, S., Rajpal, R., Srivastava, P.: Exploration of wall angle and tool rotation on surface roughness in negative incremental forming process. J. Phy : Conf. Ser. 1950, 012092 (2021)

Kumar, A., Chauhan, M., Sandhu, J.K., Kumar, A.: Study of process conditions on surface roughness in Incremental Forming Process, J. Phy.: Conf. Ser. 012090 (2021). (1950)

Keyvan Hosseinkhani, E.-G., Ng: A Unique methodology for tool life prediction in machining. J. Manuf. Mater. Proc. 4(1), 16 (2020)

Singh, G., Pandey, K.N.: Effect of cryogenic treatment on properties of materials: A review. Proc. Inst. Mech. Eng. Part E: J. Proc. Mech. Eng. 236, 4 (2022)

Priya Jadhav, S., Kumar, A., Bongale: Optimization of cutting forces by cryogenic treatment on tungsten carbide inserts during dry turning of the P 20 tool steel. Mat. Today Proc. 28, 4, 2485–2493 (2020)

Yooliengpun, C., Bandasak, N., Tuchinda, K., Diewwanit, O.: Effect of cryogenic treatment of cemented tungsten carbide tools for die application. IOP Conf. Ser. : Mat. Sci. Eng. 1048, 012002 (2021)

Ghazali, M.H.M., Mazlan, A.Z.A., Wei, L.M., Tying, C.T., Sze, T.S., Jamil, N.I.M.: Effect of machining parameters on the surface roughness for different type of materials. IOP Conf. Ser. : Mater. Sci. Eng. 530, 012008 (2019)

Gandjar Kiswanto, Azmi, M., Mandala, A., Ko, T.J.: The effect of machining parameters to the surface roughness in low speed machining micro-milling inconel 718. Mat. Sci. Eng. 654, 012014 (2019). IOP Conf. Ser.

Rajesh Kumar Bhushan: Effect of tool wear on surface roughness in machining of AA7075/10 wt.% SiC composite. Comp. Part. C. 8, 100254 (2022)

Selim Gurgen, D., Tali, M.C., Kushan: An Investigation on surface roughness and tool wear in turning operation of Inconel 718. J. Aero. Tech. Manag. 11, e1319

Wassila Frifita, Sahbi Ben Salem, Abdelkrim Haddad, Mohamed Athmane Yallese: Optimization of machining parameters in turning of Inconel 718 Nickel-base super alloy. Mech. Ind. 21, 2 (2020). (2019)

Smita Padhan, N.K., Wagri, L., Dash, A., Das, S.R., Das: Mohammad Rafighi, Priyaranjan Sharma: Investigation on surface integrity in hard turning of AISI 4140 steel with SPPP-AlTiSiN coated carbide insert under nano-MQL. Lubricants. 11(2), 49 (2023)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

R, P.C., Reddy, T.V.S., Gawade, N. et al. Cutting force and surface roughness evaluation of cryogenic treated inserts for machining en24 grade alloy steel: RSM modelling approach. Int J Interact Des Manuf (2024). https://doi.org/10.1007/s12008-024-01889-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-024-01889-w