Abstract

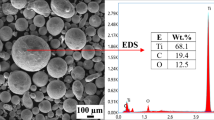

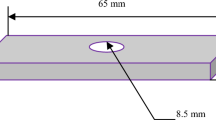

The deposition parameters frequently have a significant impact on the characteristics of plasma spray coating. Due to the intricate chemical and thermodynamics processes, it is challenging to study and create a complete model of plasma spray process. The use of WC-based coatings, which offers exceptional wear resistance, in turbomachinery components such as blades, vanes, extend their service life and lowers need of maintenance. The objective of this investigation is to develop a predictive model for mechanical properties of plasma deposited WC20Cr3C27Ni coatings using a back propagation neural network. Additionally, the study also analyses the impact of deposition parameters irrespective of the intermediate process. The change in porosity, nano-hardness, and sliding wear rate of coatings under various powder feed rate, stand-off distance, and powder gas N2 flow rate was predicted using back propagation neural network algorithm. The developed model accurately predicted the characteristics of WC-based coatings, evidenced by a comparison between predicted and experimental results that shows similar trends. In order to specifically evaluate each input variable’s relative importance for improving prediction accuracy, the mean impact value analysis was used.

Similar content being viewed by others

Data availability

The authors also declare that the data is available on the request.

References

Landes, K.: Diagnostics in plasma spraying techniques. Surf. Coat. Technol. 201, 1948–1954 (2006)

Hermanek, F.J.: Thermal Spray Terminology and Company Origins. ASM International (2001)

Pawlowski, L.: The Science and Engineering of Thermal Spray Coatings. Wiley (2008). https://doi.org/10.1002/9780470754085

Bhosale, D.G., Dorlikar, C., Bhosale, A.P., Pasare, V., Maurya, B., Korgaonkar, S., Ginwal, V., Ram Prabhu, T.: Performance of thermal-sprayed WC–Cr3C2–Ni coatings in slurry erosion for hydrodynamic. Tribol. Mater. Surf. Interfaces. Mater. Surf. Interfaces 16(4), 292–302 (2022)

Ganesan, P., Jenifer Rathna, S., Saidur, R.: Application of artificial neural network to map the performance characteristics of boiler using different algorithms. Int. J. Green Energy 18(11), 1091–1103 (2021)

Bhosale, D.G., Rathod, W.S.: Tribo-behaviour of APS and HVOF sprayed WC–Cr3C2–Ni coatings for gears. Surf. Eng. 37(1), 80–90 (2021)

Nallathambi, K., Senthilkumar, C., Elaiyarasan, U.: Deposition rate and microhardness analysis on electrical discharge coating of AA7075 using response surface methodology. Int. J. Interact. Des. Manuf. (2023). https://doi.org/10.1007/s12008-023-01370-0

Thirumalaikumarasamy, D., Shanmugam, K., Balasubramanian, V.: Effect of atmospheric plasma spraying parameters on porosity level of alumina coatings. Surf. Eng. 28(10), 759–766 (2012)

Fahad Hasan, Md., Wang, J., Berndt, C.C.: Effect of power and stand-off distance on plasma sprayed hydroxyapatite coatings. Mater. Manuf. Processes 28, 1279–1285 (2013)

Saaedi, J., Coyle, T.W., Arabi, H., Mirdamadi, S., Mostaghimi, J.: Effects of HVOF process parameters on the properties of Ni–Cr coatings. J. Therm. Spray Technol. 19, 521–530 (2010)

Bolelli, G., Berger, L.-M., MatteoBonetti, L.L.: Comparative study of the dry sliding wear behaviour of HVOF-sprayed WC–(W, Cr)2C–Ni and WC–CoCr hard metal coatings. Wear 309, 96–111 (2014)

Bhosale, D.G., Rathod, W.S., Nagaraj, M.: High-temperature erosion and sliding wear of thermal sprayed WC–Cr3C2–Ni coatings. Mater. High Temp. 38(6), 464–474 (2021)

Murariu, A.C., Cernescu, A.V., Perianu, I.-A.: The effect of saline environment on the fatigue behaviour of HVOF-sprayed WC–CrC–Ni coatings. Surf. Eng. 34, 755–761 (2018)

Bhosale, D.G., Rathod, W.S.: Investigation on wear behaviour of SS 316L, atmospheric plasma and high velocity oxy-fuel sprayed WC–Cr3C2–Ni coatings for fracturing tools. Surf. Coat. Technol. 2020, 390 (2020)

RaghavendraNaik, K., Kumar, R.K., Saravanan, V., Seetharamu, S., Sampathkumaran, P.: The study of Cr3C2–25NiCr and 35WC-Co/65NiCrBSi-based HVOF coatings for high-temperature erosion resistance application. Tribol. Mater. Surf. Interfaces. Mater. Surf. Interfaces 16(1), 10–22 (2022)

Singh, G., Kumar, S., Sehgal, S.S., Gill, H.S.: Investigation on the impact of physical properties of the coal-ash slurries on the erosion wear performance of WC coated steel by using Image processing technique. Int. J. Coal Prep. Util. 42, 2406–2426 (2022)

Wang, D.C., Wu, C.L., Zhang, S., Zhang, C.H., Zhang, D.X., Sun, X.Y.: Cavitation erosion and corrosion-cavitation synergism behaviour of CoCrFeNiMnTix high entropy alloy coatings prepared by laser cladding. Corros. Eng. Sci. Technol. 58, 766–774 (2023)

Ritapure, P.P., Damale, A.V., Yadav, R.G., Kharde, Y.R.: Optimization of dry sliding wear characteristics of Al–25Zn/SiC hybrid composites by graphite reinforcement using artificial neural network and Taguchi’s method. Tribol. Mater. Surf. Interfaces. Mater. Surf. Interfaces 16(1), 76–89 (2022)

Li, M., Christofides, P.D.: Modeling and control of high-velocity oxygen -fuel (HVOF) thermal spray: a tutorial review. J Therm Spray Tech. 18, 753 (2009)

Dongmo, E., Wenzelburger, M., Gadow, R.: Analysis and optimization of the HVOF process by combined experimental and numerical approaches. Surf. Coat. Technol. 202, 4470–4478 (2008)

Tabbara, H., Gu, S., McCartney, D.G.: Computational modelling of titanium particles in warm spray. Comput. Fluids 44, 358–368 (2011)

Mehta, A., Vasudev, H., Thakur, L.: Applications of numerical modelling techniques in thermal spray coatings: a comprehensive review. Int. J. Interact. Des. Manuf. (2023). https://doi.org/10.1007/s12008-023-01511-5

Heydari-Astaraee, A., Colombo, C., Bagherifard, S.: Numerical modeling of bond formation in polymer surface metallization using cold spray. J. Therm. Spray Technol. 30, 1765–1776 (2021)

Wen, K., Liu, X., Zhou, K., Liu, M., Zhu, H., Huang, J., et al.: 3D time-dependent numerical simulation for atmospheric plasma spraying. Surf. Coat. Technol. 371, 344–354 (2019)

Prashar, G., Vasudev, H., Bhuddhi, D.: Additive manufacturing: expanding 3D printing horizon inindustry 4.0. Int. J. Interact. Des. Manuf. 17(5), 2221–2235 (2022)

Satyavathi Yedida, V.V., Mehta, A., Vasudev, H., Singh, S.: Role of numerical modeling in predicting the oxidation behavior of thermal barrier coatings. Int. J. Interact. Des. Manuf. (2023). https://doi.org/10.1007/s12008-023-01306-8

Singh, J., Vasudev, H., Szala, M., Gill, Harjot Singh: Neural computingfor erosion assessment in Al–20TiO2 HVOF thermal spray coating. Int. J. Interact. Des. Manuf. (2023). https://doi.org/10.1007/s12008-023-01372-y

Govind Sanjeev Kumar, L., Thirumalaikumarasamy, D., Karthikeyan, K., Mathanbabu, M., Sonar T.: Optimization of process parameters for minimizing porosity level and maximizing hardness of AA2024 alloy coating on AZ31Balloy using computational response surface methodology. Int. J. Interact. Des. Manuf. (2023)

Frochte, J.: Maschinelles Lernen: Grundlagen und Algorithmen in Python. Carl Hanser Verlag GmbH Co KG (2019)

Banka, J., Rai, A.K.: Erosion and flow visualization in centrifugal slurry pumps: a comprehensive review of recent developments and future outlook. Part. Sci. Technol. 42(3), 427–459 (2024)

Hayman, S.: The mcculloch-pitts model. Int. Jt. Conf. Neural Netw. 6, 4438–4439 (1999)

da Alexandrino, P.S.L., Gomes, G.F., Cunha, S.S., Jr.: A robust optimization for damage detection using multiobjective genetic algorithm, neural network and fuzzy decision making. Inverse Probl. Sci. Eng. 28, 21–46 (2020)

Lia, X., Zhu, Y., Xiao, G.: Application of artificial neural networks to predict sliding wear resistance of Ni–TiN nano composite coatings deposited by pulse electrodeposition. Ceram. Int. 40(8), 11767–11772 (2014)

Bhosale, D.G., Bhosale, P., Bhosale, A., Ingale, Y., Vasudev, H., Ram, Prabhu T.: ANN supported study on the performance and slurry erosion resistance of thermal sprayed WC20Cr3C27ni coatings. Surf. Rev. Lett. (2023). https://doi.org/10.1142/S0218625X24020013

Gupta, G., Satapathy, A., Sofiane: Erosion wear response of glass microsphere coatings: parametric appraisal and prediction using Taguchi method and neural. Tribol. Trans.. Trans. 57(5), 899–907 (2014)

Singh, J., Singh, S., Vasudev, H., Singh Chohan, J., Kumar, S.: Neural computing and Taguchi’s methodbased study on erosion of advanced Mo2C–WC10Co4Cr coating for the centrifugal pump. Adv. Mater. Process. Technol. (2023). https://doi.org/10.1080/2374068X.2023.2221884

Dombi, G.W., Nandi, P., Saxe, J.M., Ledgerwood, A.M., Lucas, C.E.: Prediction of rib fracture injury outcome by an artificial neural network. J. Trauma Acute Care Surg. 39, 915–921 (1995)

Jiang, J.-L., Su, X., Zhang, H., Zhang, X.-H., Yuan, Y.-J.: A novel approach to active compounds identification based on support vector regression model and mean impact value. Chem. Biol. Drug Des. 81, 650–657 (2013)

Jiang, J.-L., Li, Z.-D., Zhang, H., Li, Y., Zhang, X.-H., Yuan, Y., Yuan, Y.: Feature selection for the identification of antitumor compounds in the alcohol total extracts of Curcuma longa. Planta Med. 80, 1036–1044 (2014)

Vasant, P.M., Rahman, I., Singh, B.S.M., Abdullah-Al-Wadud, M.: Optimal power allocation scheme for plug-in hybrid electric vehicles using swarm intelligence techniques. Cogent Eng. 3(1), 1203083 (2016)

Cao, C., Han, T., Yaxin, Xu., Li, W., Yang, X., Kaiwei, Hu.: The associated effect of powder carrier gas and powder characteristics on the optimal design of the cold spray nozzle. Surf. Eng. 36, 1081–1089 (2020)

Jiang, J.-L., Xin, Su., Ding, H.-T., Zhou, P.-P., Han, S.-N., Yuan, Y.-J.: A novel approach to evaluate the quality and identify the active compounds of the essential oil from Curcuma longa L. Anal. Lett. 46, 1213–1228 (2013)

Heydari, A., Garcia, D.A., Keynia, F., Bisegna, F., De Santoli, L.: Hybrid intelligent strategy for multifactor influenced electrical energy consumption forecasting. Energy Sour. Part B Econ. Plan. Policy 14, 341–358 (2019)

Shanti Kiran, Z., Babu, V., Srinadh, K.: Investigation of the microhardness and solid particle erosive wear of organoclay-filled glass-epoxy nanocomposites and optimisation using Taguchi method. Aust. J. Mech. Eng. 18(3), 364–374 (2020)

Mantry, S., Jha, B.B., Mandal, A., Chakraborty, M., Mishra, B.K.: Abrasive wear analysis of plasma-sprayed LaCeYSZ nanocomposite coatings using experimental design and ANN. Tribol. Trans.. Trans. 57, 919–927 (2014)

Tillmann, W., Vogli, E., Baumann, I., Kopp, G., Weihs, C.: Desirability-based multi-criteria optimization of HVOF spray experiments to manufacture fine structured wear-resistant 75Cr3C2-25 (NiCr20) coatings. J. Therm. Spray Technol. 19, 392–408 (2010)

Acknowledgements

The authors wish to thank Metallizing Equipment Pvt. Ltd., Jodhpur, India, for providing the coating facility. The authors are grateful to IIT Bombay, India, for providing the testing facilities such as SEM and nano-indentation. This research work did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Suryawanshi, S., Bhosale, D.G., Vasudev, H. et al. Back propagation model for prediction of deposition parameters in plasma sprayed WC-based coatings. Int J Interact Des Manuf (2024). https://doi.org/10.1007/s12008-024-01863-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-024-01863-6