Abstract

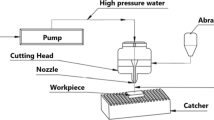

This paper describes an experimental investigation, modelling and optimization during abrasive water jet machining (AWJM) of glass fibre reinforced polymer composite. Four process parameters namely water pressure, stand-off distance, traverse rate and abrasive mass flow rate are considered to study their influence on maximum delamination length (Max. DLL), surface roughness (Ra) and kerf taper (Kt). The second-order regression models are developed for the maximum delamination length, surface roughness and kerf taper in AWJM of glass fibre reinforced polymer composite using response surface methodology based central composite design approach. From the regression models, it is revealed that delamination decreases with an increase in abrasive mass flow rate, with a decrease in traverse rate. Surface roughness decreases with increase in water pressure and decrease in traverse rate. Kerf taper decreases with increase in water pressure; and decrease in traverse rate and stand-off distance. Further, response surface methodology based desirability function is performed to minimize the Max. DLL, Ra and Kt and the desirability values were found for Ra = 0.936, Kt = 0.942 and Max. DLL = 1 with a combined desirability rating of 0.959 which was reasonably good and acceptable. From the confirmation test of multi-response optimization, it was obvious that the percentage error at optimum level of process parameters for Ra, Kt, and Max. DLL were less than 6.312%, 7.229%, and 4.318%, respectively.

Similar content being viewed by others

References

Campbell, F.C.: Introduction to Composite Materials, Structural Composite, Materials, ASM International, USA (2010)

Kovacevic, R., Hashish, M., Mohan, R., Ramulu, M., Kim, T.J., Geskin, E.S.: State of the art of research and development in abrasive water jet machining. J. Manuf. Sci. Eng. 119, 776–785 (1997). https://doi.org/10.1115/1.2836824

Jain, V.K.: Advanced Machining Processes. Allied publishers private limited, New Delhi (2005)

Momber, A.W., Kovacevic, R.: Principles of abrasive water jet machining. Springer Science & business media, London (1998)

Dahiya, A.K., Bhuyan, B.K., Kumar, S.: Perspective study of abrasive water jet machining of composites—a review. J. Mech. Sci. Technol. 36, 213–224 (2022). https://doi.org/10.1007/s12206-021-1220-x

Dahiya, A.K., Bhuyan, B.K., Kumar, S.: A Review on Machining Potential of Composite Materials During Abrasive Water Jet Machining. Lect. Notes Mech. Eng. 1301–1315 (2022) https://doi.org/10.1007/978-981-16-2794-1_111

Kuttan, A.A., Rajesh, R., DevAnand, M.: Abrasive water jet machining techniques and parameters: a state of the art, open issue challenges and research directions. J. Braz. Soc. Mech. Sci. Eng. 43(220), 1–14 (2021). https://doi.org/10.1007/s40430-021-02898-6

Lemma, E., Chen, L., Siores, E., Wang, J.: Study of cutting fiber-reinforced composites by using abrasive water-jet with cutting head oscillation. Compos. Struct. 57, 297–303 (2002). https://doi.org/10.1016/S0263-8223(02)00097-1

Azmir, M.A., Ahsan, A.K.: Investigation on glass/epoxy composite surfaces machined by abrasive water jet machining. J. Mater. Process. Technol. 198, 122–128 (2007). https://doi.org/10.1016/j.jmatprotec.2007.07.014

Shanmugam, D.K., Nguyen, T., Wang, J.: A study of delamination on graphite/epoxy composites in abrasive water jet machining. Compos. Part A 39, 923–929 (2008)

Izzet, K., Gokhan, A., Kerim, A.: An investigation on the kerf width in abrasive waterjet cutting of granitic rocks. Arab. J. Geosci. 7, 2923–2932 (2014). https://doi.org/10.1007/s12517-013-0984-4

Alberdi, A., Artaza, T., Suarez, A., Rivero, A., Girot, F.: An experimental study on abrasive waterjet cutting of CFRP/Ti6Al4V stacks for drilling operations. Int. J. Adv. Manuf. Technol. (2016). https://doi.org/10.1007/s00170-015-8192-x

Dhanawade, A., Kumar, S., Kalmekar, R.V.: Abrasive Water Jet Machining of Carbon Epoxy Composite. Def. Sci. J. 66(5), 522–528 (2016)

Ahmed, T.M., Mesalamy, A.S., Youssef, A., Midany, T.T.: Improving surface roughness of abrasive waterjet cutting process by using statistical modelling. CIRP J. Manuf. Sci. Technol. 22, 30–36 (2018). https://doi.org/10.1016/j.cirpj.2018.03.004

Prasad, S.K., Chaitanya, G.: Analysis of delamination in drilling of GFRP composites using Taguchi Technique. Mater. Today Proc. 18(7), 3252–3261 (2019)

Banon, F., Sambruno, A., Ruiz-Gracia, R., Salgueroet, J., Mayuet, P.F.: Study of the influence of cutting parameters on surface quality in AWJM machining of thermoplastic matrix composites. Proc. Manuf. 41, 233–242 (2019). https://doi.org/10.1016/j.promfg.2019.07.051

Banon, F., Sambruno, A., Batista, M., Simonet, B., Salgueroet, J.: Study of the surface quality of carbon fiber–reinforced thermoplastic matrix composite (CFRTP) machined by abrasive water jet (AWJM). Int. J. Adv. Manuf. Techn. 107, 3299–3313 (2020)

Kale, A., Singh, S.K., Sateesh, N., Subbiah, R.: A review on abrasive water jet machining process and its process parameters. Mater. Today: Proc. 26(2), 1032–1036 (2020). https://doi.org/10.1016/j.matpr.2020.01.309

Dahiya, A.K., Bhuyan, B.K., Kumar, S.: Optimization of process parameters for surface roughness of GFRP with AWJ machining using Taguchi and GRA methods. Int. J. Mod. Manuf. Technol. 13(2), 2021 (2021)

Rammohan, S., Kumaran, S.T., Uthayakumar, M., Korniejenko, K., Nykiel, M., Velayutham, A.: Prediction of abrasive waterjet machining parameters of military-grade armor steel by semi-empirical and regression models. Materials. 15, 4368 (2022). https://doi.org/10.3390/ma15124368

Iyer, N.P., Arunkumar, N.: Investigation of abrasive water jet machining parameters of Bismaleimide composites. Mater. Manuf. Process. (2022). https://doi.org/10.1080/10426914.2022.2032145

Dhanawade, A., Wazarkar, S., Kumar, S.: Erosion model for abrasive water jet machining of composite materials. J Braz. Soc. Mech. Sci. Eng. 44, 268 (2022). https://doi.org/10.1007/s40430-022-03565-0

Singh, D., Shukla, R.S.: Investigation of kerf characteristics in abrasive water jet machining of inconel 600 using response surface methodology. Def. Sci. J. 70(3), 312–322 (2020)

Dumbhare, P.A., Dubey, S., Deshpande, Y.V., Andhare, A.B., Barve, P.S.: Modelling and multi-objective optimization of surface roughness and kerf taper angle in abrasive water jet machining of steel’. J. Braz. Soc. Mech. Sci. Eng. 40, 259 (2018). https://doi.org/10.1007/s40430-018-1186-5

Thakur, R.K., Singh, K.K., Ramkumar, J.: Delamination analysis and hole quality of hybrid FRP composite using abrasive water jet machining. Mater. Today: Proc. 33(8), 5653–5658 (2020)

Pahuja, R., Ramulu, M.: Abrasive water jet machining of Titanium (Ti6Al4V)–CFRP stacks—a semi analytical modeling approach in the prediction of kerf geometry. J. Manuf. Process. 39, 327–337 (2019). https://doi.org/10.1016/j.jmapro.2019.01.041

Kumar, P., Salunkhe, S., Kant, R.: Experimental investigation of kerf characteristics of kevlar49 epoxy composite machined by abrasive water jet. Int. J. Mod. Manuf. Technol. 11(2), 13–18 (2019)

Tripathi, D.R., Vachhani, K.H., Kumari, S., et al.: Experimental investigation on material removal rate during abrasive water jet machining of GFRP composites. Mater. Today Proc. 26(2), 1389–1392 (2020). https://doi.org/10.1016/j.matpr.2020.02.280

Tripathi, D.R., Vachhani, K.H., Bandhu, D., et al.: Experimental investigation and optimization of abrasive waterjet machining parameters for GFRP composites using metaphor-less algorithms. Mater. Manuf. Process. 36(7), 803–813 (2021)

Bandhu, D., Abhishek, K.: Assessment of weld bead geometry in modified shortcircuiting gas metal arc welding process for low alloy steel. Mater. Manuf. Process. 36(12), 1384–1402 (2021)

Bandhu, D., Kumari, S., Prajapati, V.K., et al.: Experimental investigation and optimization of RMDTM welding parameters for ASTM A387 grade 11 steel. Mater. Manuf. Process. 36(13), 1524–1534 (2021)

Dinbandhu, Abhishek, K.: Parametric Optimization and Evaluation of RMDTM Welding Performance for ASTM A387 Grade 11 Steel Plates Using TOPSIS-Taguchi Approach. In: Patnaik, A., Kozeschnik, E., Kukshal, V. (eds) Advances in Materials Processing and Manufacturing Applications. iCADMA 2020. Lecture Notes in Mechanical Engineering. (2021) Springer, Singapore. https://doi.org/10.1007/978-981-16-0909-1_22

Natarajan, Y., Murugesan, P.K., Mohan, M., Khan, S.A.L.A.: Abrasive water jet machining process: a state of art of review. J. Manuf. Process. 49, 271–322 (2020). https://doi.org/10.1016/j.jmapro.2019.11.030

Llanto, J.M., Tolouei-Rad, M., Vafadar, A., Aamir, M.: Recent progress trend on abrasive waterjet cutting of metallic materials: a review. Appl. Sci. 11, 3344 (2021). https://doi.org/10.3390/app11083344

Montgomery, D.C.: Design and analysis of experiments. Wiley, New York (1997)

Basanta, B.K., Yadava, V.: Experimental modelling and multi-response optimization of travelling wire electrochemical spark machining of Pyrex glass. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 228(8), 902–916 (2014). https://doi.org/10.1177/0954405413514745

Panneerselvam, R.: Design and Analysis of Experiments. PHI learning, Delhi (2012)

Azmir, M.A., Ahsan, A.K.: Study of abrasive water jet machining process on glass/ epoxy composite laminate. J. Mater. Process. Technol. 209(20), 6169–6173 (2009). https://doi.org/10.1016/j.jmatprotec.2009.08.011

Dhanawade, A., Kumar, S.: Abrasive water jet machining of carbon epoxy composite: cutting performance, predictive models and optimization. Indian Journal of Engineering & Material Sciences. 26, 265–275 (2019)

Shanmugam, D.K., Masood, S.: An investigation on kerf characteristics in abrasive waterjet cutting of layered composites. J. Mater. Process. Technol. 209, 3887 (2009)

Dhanawade, A., Kumar, P., Kumar, S.: Experimental study on abrasive water jet machining of carbon epoxy composite. Adv. Mater. Process. Technol. 6(1), 40–53 (2020). https://doi.org/10.1080/2374068X.2019.1703338

Fuse, K., Chaudhari, R., Jayvora, J., Patel, V.K., de Lacalle, L.N.L.: Multi-Response optimization of abrasive waterjet machining of Ti6Al4V using integrated approach of utilized heat transfer search algorithm and RSM. Materials 14, 7746 (2021)

Kolli, M., RamPrasad, A.V.S., Naresh, D.S.: Multi-objective optimization of AAJM process parameters for cutting of B4C/Gr particles reinforced Al 7075 composites using RSM-TOPSIS approach. SN Appl. Sci. 3, 711 (2021). https://doi.org/10.1007/s42452-021-04699-x

Gnanavelbabu, A., Arunachalam, V., SunuSurendran, K.T., Saravanan, P.: Optimization of abrasive water jet machining parameters on AA6061/B4C/hBN hybrid composites using grey-RSM. IOP Conf. Ser. Mater. Sci. Eng. 764, 012011 (2020). https://doi.org/10.1088/1757-899X/764/1/012011

Thamizhvalavan, P., Yuvaraj, N., Arivazhagan, S.: Abrasive water jet machining of Al6063/B4C/ZrSiO4 hybrid composites: a study of machinability and surface characterization analysis. SILICON 14, 1093–1121 (2022). https://doi.org/10.1007/s12633-020-00888-2

Dahiya, A.K., Bhuyan, B.K., Acharya, V., Kumar, S.: Optimization of process parameters for machining defects of glass fibre reinforced polymer composite machined by AWJM. Mater. Today Proc. (2022). https://doi.org/10.1016/j.matpr.2022.12.138

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dahiya, A.K., Bhuyan, B.K. & Kumar, S. Abrasive water jet machining of glass fibre reinforced polymer composite: experimental investigation, modelling and optimization. Int J Interact Des Manuf 17, 1933–1947 (2023). https://doi.org/10.1007/s12008-023-01312-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-023-01312-w