Abstract

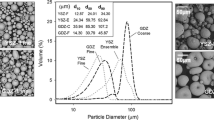

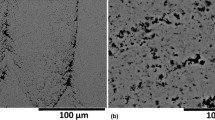

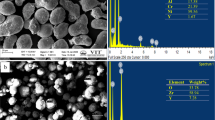

When the operational life of a gas turbine is extended, the operating efficiency rises, and emissions fall. For many years, researchers have been interested in the design and development of leading gas turbine blades and other engine components that are subjected to a variety of rigorous operating circumstances. The input and output parameters and resources were studied to understand the role of Sustainable manufacturing and design of oxidation resistant YSZ thermal barrier coating system. A case study of oxidation performance of YSZ plasma sprayed coating was incorporated in the current study to understand the structure-property correlation of YSZ coatings. The different YSZ coatings were also included to compare the result with the presented coating. The coating showed a porosity of around 11%, which is helpful in compensating the cyclic oxidation conditions. Moreover, there was a significant difference observed in the weight gain of SS-304 stainless steel and YSZ coating.

Similar content being viewed by others

References

Gössling, S., Humpe, A.J.G.E.C.: The global scale, distribution and growth of aviation: Implications for climate change. ;65:102194. (2020)

El Takriti, S., Pavlenko, N.: Searle SJRàhtosdfpA-A. Mitigating international aviation emissions. (2017)

Chen, H.-F., Zhang, C., Liu, Y.-C., Song, P., Li, W.-X., Yang, G., et al.: Recent progress in thermal/environmental barrier coatings and their corrosion resistance. ;39:498–512. (2020)

Masson-Delmotte, V., Zhai, P., Pirani, A., Connors, S.L., Péan, C., Berger, S., et al.: Climate change 2021: the physical science basis. ;2. (2021)

Lashmi, P., Ananthapadmanabhan, P., Unnikrishnan, G., Aruna, S.J.J.E.C.S.: Present status and future prospects of plasma sprayed multilayered thermal barrier coating systems. ;40:2731–45. (2020)

Zeng, Y., Friess, D.A., Sarira, T.V., Siman, K., Koh, L.P.J.C.B.: Global potential and limits of mangrove blue carbon for climate change mitigation. ;31:1737–43. e3. (2021)

Chen, H., Zhang, C., Xuan, J., Liu, B., Yang, G., Gao, Y., et al.: Effect of TGO evolution and element diffusion on the life span of YSZ/Pt–Al and YSZ/NiCrAlY coatings at high temperature. ;46:813–23. (2020)

Lv, B., Jin, X., Cao, J., Xu, B., Wang, Y., Fang, D.J.J.E.C.S.: Adv. Numer. Model. Environ. barrier Coat. Syst. gas turbines. 40, 3363–3379 (2020)

Rauf, A., Yu, Q., Jin, L., Zhou, C.J.S.M.: Microstructure and thermal properties of nanostructured lanthana-doped yttria-stabilized zirconia thermal barrier coatings by air plasma spraying. ;66:109–12. (2012)

Park, K., Kim, K., Kim, D., Moon, B., Park, S., Seok, C.-S.J.C.I.: Failure mechanism of plasma-sprayed thermal barrier coatings under high-temperature isothermal aging conditions. ;47:15883–900. (2021)

Mathanbabu, M., Thirumalaikumarasamy, D., Thirumal, P., Ashokkumar, M.J.M.T.P.: Study on thermal, mechanical, microstructural properties and failure analyses of lanthanum zirconate based thermal barrier coatings. A review. 46, 7948–7954 (2021)

Kumar, D., Npandey, K.J.S.: A comparative study of erosion wear rate of conventional and nonconventional thermal barrier coatings on IN800 superalloys. ;46:1–17. (2021)

Kumar, N., Mahade, S., Ganvir, A., Joshi, S.J.S., Technology, C.: Understanding the influence of microstructure on hot corrosion and erosion behavior of suspension plasma sprayed thermal barrier coatings. ;419:127306. (2021)

Yunus, S.M., Mahalingam, S., Manap, A., Afandi, N.M., Satgunam, M.J.C.: Test-rig simulation on hybrid thermal barrier coating assisted with cooling air system for advanced gas turbine under prolonged exposures—A review. ;11:560. (2021)

Fan, W., Bai, Y., Wang, Y., He, T., Gao, Y., Zhang, Y., et al.: Microstructural design and thermal cycling performance of a novel layer-gradient nanostructured Sc2O3–Y2O3 co-stabilized ZrO2 thermal barrier coating. ;829:154525. (2020)

Stollberg, D., Hampikian, J., Riester, L., Carter, W.J.M.S.: A E. Nanoindentation measurements of combustion CVD Al2O3 and YSZ films. ;359:112–8. (2003)

Islak, S., Buytoz, S.: Plazma Püskürtme Yöntemiyle AISI 304 Paslanmaz Çelik Yüzeyinde Elde Edilen ZrO2/Al2O3-% 13TiO2 Kompozit Kaplamasının Mikroyapı Özellikleri. 6th International Advanced Technologies Symposium (IATS’11), 16–18 …(2011)

Jamnapara, N., Mukherjee, S.: Coatings for High Temperature Applications, pp. 161–200. World Scientific, High Temperature Corrosion (2016)

Ramesh, M., Marimuthu, K.J.D.J.N.B.: Microstructural, thermal and wear behavior of YSZ/Al2O3 thermal barrier coatings for gun barrel applications. ;15:527–36. (2020)

JASIK AJOpK:. The numerical analysis of stress and temperature distribution in a double-ceramic-layer (DCL) type of La2Zr2O7/8YSZ thermal barrier coatings (TBC) in as-sprayed state. (2018)

Keyvani, A., Saremi, M., Heydarzadeh Sohi, M.J.J.U.G., Materials, N.: Oxidation resistance of the nanostructured YSZ coating on the IN-738 superalloy. ;47:89–96. (2014)

Doleker, K.M., Odabas, O., Ozgurluk, Y., Askerov, H., Karaoglanli, A.C.J.M.R.E.: Effect of high temperature oxidation on Inconel 718 and Inconel 718/YSZ/Gd2Zr2O7. ;6:086456. (2019)

Liu, Y., Fei, Y., Wang, Z., Xu, J.J.C.I.: Evaluation of mechanical properties of YSZ TBCs doped by different ratios of Eu3 + ions after isothermal oxidation. (2022)

Mahade, S., Ruelle, C., Curry, N., Holmberg, J., Björklund, S., Markocsan, N., et al.: Understanding the effect of material composition and microstructural design on the erosion behavior of plasma sprayed thermal barrier coatings. ;488:170–84. (2019)

Abubakar, A.A., Arif, A.F.M., Akhtar, S.S.J.C.I.: Evolution of internal cracks and residual stress during deposition of TBC. ;46:26731–53. (2020)

Wang, L., Fan, Q., Liu, Y., Li, G., Zhang, H., Wang, Q., et al.: Simulation of damage and failure processes of thermal barrier coatings subjected to a uniaxial tensile load. ;86:89–97. (2015)

Yan, J., Wang, X., Chen, K., Lee, K.N.J.C.: Sintering modeling of thermal barrier coatings at elevated temperatures: A review of recent advances. ;11:1214. (2021)

Huang, Y.-P., Wei, Z.-Y., Cai, H.-N., Liu, Y., Han, X.-C.J.C.I.: The effects of TGO growth stress and creep rate on TC/TGO interface cracking in APS thermal barrier coatings. ;47:24760–9. (2021)

Fang, G., Gao, X., Song, Y.J.C.: A Review on Ceramic Matrix Composites and Environmental Barrier Coatings for Aero-Engine: Material Development and Failure Analysis. ;13:357. (2023)

Long, Y., Wang, Y., Chen, X., Sang, R.J.C.I.: Influence of crack features on heat transfer characteristic and cracking behaviour of APS-YSZ coating: A numerical simulation study. ;47:22209–18. (2021)

Gok, M.G., Karabas, M.J.C.I.: Production of Re doped La2Zr2O7 based TBCs and numerical analysis of their use on IC engine piston surface. ;48:11173–80. (2022)

Liang, X., Wang, Y., Wang, S., Liu, Z., Suo, H.J.J.E.C.S.: CMAS corrosion resistance, thermal shock resistance and numerical simulation of novel surface micromesh thermal barrier coatings. (2022)

Kiełczawa, T., Sokołowski, P.: The Numerical Analysis of Plasma Sprayed YSZ Particles Behavior in the Microtextured Substrate Boundary Layer. ITSC2022, pp. 89–99. ASM International (2022)

Rahimi, J., Sigaroodi, M.R.J., Poursaeidi, E.J.C.I.: Thermal shock resistance of thermal barrier coating with different bondcoat types and diffusion pre-coating. ;49:2061–72. (2023)

Dehnou, K.H., Norouzi, G.S., Majidipour, M.J.R.: A review: studying the effect of graphene nanoparticles on mechanical, physical and thermal properties of polylactic acid polymer. ;13:3976–4006. (2023)

Mehta, A., Vasudev, H., Singh, S., Prakash, C., Saxena, K.K., Linul, E., Buddhi, D., Xu, J.: Processing and Advancements in the development of thermal barrier coatings: A Review, Coatings. 121318. (2022)

Pramanik, A., Basak, A.K., Prakash, C.: Understanding the wire electrical discharge machining of Ti6Al4V alloy. Heliyon. 5, e01473 (2019)

Basak, A.K., Pramanik, A., Prakash, C.: Deformation and strengthening of SiC reinforced Al-MMCs during in-situ micro-pillar compression. Mater. Sci. Engineering: A. 763, 138141 (2019)

Prakash, C., Singh, S., Gupta, M.K., Mia, M., Królczyk, G., Khanna, N.: Synthesis, characterization, corrosion resistance and in-vitro bioactivity behavior of biodegradable Mg–Zn–Mn–(Si–HA) composite for orthopaedic applications. Materials. 11, 1602 (2018)

Prakash, C., Singh, S., Pabla, B.S., Sidhu, S.S., Uddin, M.S.: Bio-inspired low elastic biodegradable Mg-Zn-Mn-Si-HA alloy fabricated by spark plasma sintering. Mater. Manuf. Processes. 34, 357–368 (2019)

Gupta, N.K., Somani, N., Prakash, C., Singh, R., Walia, A.S., Singh, S., Pruncu, C.I.: Revealing the WEDM process parameters for the machining of pure and heat-treated Titanium (Ti-6Al-4V) Alloy. Materials. 14, 2292 (2021)

Poomathi, N., Singh, S., Prakash, C., Patil, R.V., Perumal, P.T., Barathi, V.A., Balasubramanian, K.K., Ramakrishna, S., Maheshwari, N.U.: Bioprinting in ophthalmology: current advances and future pathways,Rapid Prototyping Journal. (2018)

Singh, S., Singh, M., Prakash, C., Gupta, M.K., Mia, M., Singh, R.: Optimization and reliability analysis to improve surface quality and mechanical characteristics of heat-treated fused filament fabricated parts. Int. J. Adv. Manuf. Technol. 102, 1521–1536 (2019)

Uddin, M., Basak, A., Pramanik, A., Singh, S., Krolczyk, G.M., Prakash, C.: Evaluating hole quality in drilling of Al 6061 alloys. Materials. 11, 2443 (2018)

Kumar, R., Dubey, R., Singh, S., Singh, S., Prakash, C., Nirsanametla, Y., et al.: Multiple-criteria decision-making and sensitivity analysis for selection of materials for knee implant femoral component. Materials. 14, 2084 (2021)

Rathi, R., Prakash, C., Singh, S., Krolczyk, G., Pruncu, C.I.: Measurement and analysis of wind energy potential using fuzzy based hybrid MADM approach. Energy Rep. 6, 228–237 (2020)

Prakash, C., Kansal, H.K., Pabla, B., Puri, S.: Powder mixed electric discharge machining: an innovative surface modification technique to enhance fatigue performance and bioactivity of β-Ti implant for orthopedics application.Journal of Computing and Information Science in Engineering. ;16. (2016)

Sandhu, K., Singh, G., Singh, S., Kumar, R., Prakash, C., Ramakrishna, S., Królczyk, G., Pruncu, C.I.: Surface characteristics of machined polystyrene with 3D printed thermoplastic tool. Materials. 13, 2729 (2020)

Antil, P., Kumar Antil, S., Prakash, C., Krolczyk, G., Pruncu, C.: Multi-objective optimization of drilling parameters for orthopaedic implants. Meas. Control. 53, 1902–1910 (2020)

Kumar, A., Grover, N., Manna, A., Chohan, J.S., Kumar, R., Singh, S., Prakash, C., Pruncu, C.I.: Investigating the influence of WEDM process parameters in machining of hybrid aluminum composites. Adv. Compos. Lett. 29, 2633366X20963137 (2020)

Kumar, R., Ranjan, N., Kumar, V., Kumar, R., Chohan, J.S., Yadav, A., Sharma, S., Prakash, C., Singh, S., Li, C.: Characterization of friction stir-welded polylactic acid/aluminum composite primed through fused filament fabrication,Journal of Materials Engineering and Performance.1–19. (2021)

Singh, H., Singh, S., Prakash, C.: Current trends in biomaterials and bio-manufacturing,Biomanufacturing.1–34. (2019)

Jin, S.Y., Pramanik, A., Basak, A.K., Prakash, C., Shankar, S., Debnath, S.: Burr formation and its treatments—a review. Int. J. Adv. Manuf. Technol. 107, 2189–2210 (2020)

Prakash, C., Singh, S., Ramakrishna, S., Królczyk, G., Le, C.H.: Microwave sintering of porous Ti–Nb-HA composite with high strength and enhanced bioactivity for implant applications. J. Alloys Compd. 824, 153774 (2020)

Pandey, A., Singh, G., Singh, S., Jha, K., Prakash, C.: 3D printed biodegradable functional temperature-stimuli shape memory polymer for customized scaffoldings. J. Mech. Behav. Biomed. Mater. 108, 103781 (2020)

Mehta, A., Vasudev, H., Singh, S.: Sustainable manufacturing approach with novel thermal barrier coatings in lowering CO2 emissions: Performance analysis with probable solutions. Int. J. Interact. Des. Manuf. (2023). https://doi.org/10.1007/s12008-023-01222-x

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest statement

This article has not been submitted elsewhere for publication and authors do not have any conflict related to this manuscript and presented data.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yedida, V.S., Mehta, A., Vasudev, H. et al. Role of numerical modeling in predicting the oxidation behavior of thermal barrier coatings. Int J Interact Des Manuf (2023). https://doi.org/10.1007/s12008-023-01306-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-023-01306-8