Abstract

Assab 718 was a kind of plastic die steel and the daughter grains were the tempered sorbite after normalizing and high-temperature tempering. The daughter grains had a specific orientation relationship with the parent grains, which could be reconstructed based on the electron backscattered diffraction tests. The evolution laws from the parent grains to the daughter grains under the two forging processes were compared by HKL Channel 5. The results showed that the parent grains were finer and more evenly distributed under the new process. The recrystallization volume fraction of those grains was less than that under the traditional one. From the parent grains to the daughter grains, the orientation of the maximum texture intensity and the maximum section location was changed under the liquid core forging process. While the orientation of the maximum texture intensity of the parent grains under the traditional one was a common S-texture and that of the daughter grains was not obvious. The geometrically necessary dislocation density was calculated based on the kernel average misorientation. This study is necessary to reveal the micro-deformation mechanism of the new and the traditional forging processes. It can provide theoretical guidance for implementing the liquid core forging process.

Similar content being viewed by others

References

Yongqiang, W., Wen, F., Kaikun, W.: Numerical and physical simulation of the forging process with liquid core. Int. J. Adv. Manuf. Technol. 119(1–2), 1167–1177 (2021). https://doi.org/10.1007/s00170-021-08310-w

Yongqiang, W., Zhiren, S., Kaikun, W.: The simulation of the preparation of the ingot with liquid core. Int. J. Adv. Manuf. Technol. 116(3–4), 931–940 (2021). https://doi.org/10.1007/s00170-021-07538-w

Yongqiang, W., Kaikun, W.: The ultra-high temperature forging process based on DEFORM-3D simulation. Int. J. Interact. Des. Manuf. 16(1), 99–108 (2022). https://doi.org/10.1007/s12008-021-00811-y

Hirt, G., Shimahara, H., Seidl, I., Küthe, F., Abel, D., Schönbohm, A., Kopp, R.: Semi-solid forging of 100Cr6 and X210CrW12 steel. CIRP Ann-Manuf. Technol. 1(54), 257–260 (2005). https://doi.org/10.1016/S0007-8506(07)60097-3

Koc, M., Vazquez, V., Witulski, T., Altan, T.: Application of the finite element method to predict material flow and defects in the semi-solid forging of A356 aluminum alloys. J. Mater. Process. Technol. 59(1), 106–112 (1996). https://doi.org

Nyyssönen, T., Isakov, M., Peura, P.: Iterative determination of the Orientation Relationship between Austenite and Martensite from a large amount of Grain Pair Misorientations. Metall. Mater. Trans. A-Phys Metall. Mater. Sci. 47(6), 2587–2590 (2016). https://doi.orghttps://doi.org/10.1007/s11661-016-3462-2

Miyamoto, G., Iwata, N., Takayama, N., Furuhara, T.: Mapping the parent austenite orientation reconstructed from the orientation of martensite by EBSD and its application to ausformed martensite. Acta Mater. 58(19), 6393–6403 (2010). https://doi.org

Abbasi, M., Nelson, T., Sorensen, W., Carl, D., Wei, L.: An approach to prior austenite reconstruction. Mater. Charact. 66, 1–8 (2012). https://doi.org/10.1016/j.matchar.2012.01.010

Cayron, C., Baur, A., Logé, R.: Intricate morphologies of laths and blocks in low-carbon martensitic steels. Mater. Des. 154, 81–95 (2018). https://doi.org/10.1016/j.matdes.2018.05.033

Wu, B.B., Wang, X.L., Wang, Z.Q., Zhao, J.X., Jin, Y.H., Wang, C.S., Shang, C.J., Misra, R.D.K.: New insights from crystallography into the effect of refining prior austenite grain size on transformation phenomenon and consequent mechanical properties of ultra-high strength low alloy steel. Mater. Sci. Eng. A-Struct Mater. Prop. Microstruct. Process. 745, 126–136 (2019). https://doi.org/10.1016/j.msea.2018.12.057

Wu, B.B., Wang, Z.Q., Wang, X.L., Xu, W.S., Shang, C.J.: Toughening of martensite matrix in high strength low alloy steel: regulation of variant pairs. Mater. Sci. Eng. A-Struct Mater. Prop. Microstruct. Process. 759, 430–436 (2019). https://doi.org

Wang, Z., Song, T.T., Wang, X.L., Shang, C.J., Liu, K., Chen, B.: Orientation reconstruction of original austenite in covariant transformation structure and its application in austenite twinning. Int. J. Eng. Sci. 40(08), 945–953 (2018). https://doi.org/10.13374/j.issn2095-9389.2018.08.008

Guo, Z., Lee, C.S., Morris, J.W.: On coherent transformations in steel. Acta Mater. 52(19), 5511–5518 (2004). https://doi.org/10.1016/j.actamat.2004.08.011

Cayron, C., Artaud, B., Briottet, L.: Reconstruction of parent grains from EBSD data. Mater. Charact. 57(4), 386–401 (2006). https://doi.org/10.1016/j.matchar.2006.03.008

Wu, J., Zhang, W.Z.: The understanding and calculation of misorientation between variants based on the phase transformation. Acta Metall. Sin. 45(08), 897–905 (2009)

Flower, H.M., Lindley, T.C.: Electron backscattering diffraction study of acicular ferrite, bainite, and martensite steel microstructures. Mater. Sci. Technol. 16(1), 26–40 (2000). https://doi.org

Takayama, N., Miyamoto, G., Furuhara, T.: Effects of transformation temperature on variant pairing of bainitic ferrite in low carbon steel. Acta Mater. 60(5), 2387–2396 (2012). https://doi.org/10.1016/j.actamat.2011.12.018

Celada, C., Sietsma, J., Santofimia, M.J.: The role of the austenite grain size in the martensitic transformation in low carbon steels. Mater. Des. 167, 107625 (2019). https://doi.org

He, G., Peng, T., Jiang, B., Hu, X., Liu, Y., Wu, C.: Recrystallization Behavior and Texture Evolution in Low Carbon Steel during Hot Deformation in Austenite/Ferrite Region,Steel Res. Int.92(10),2100047-n/a(2021). https://doi.org/10.1002/srin.202100047

Mackenzie, J.K.: The distribution of rotation axes in a random aggregate of cubic crystals. Acta Mater. 12(2), 223–225 (1964). https://doi.org/10.1016/0001-6160(64)90191-9

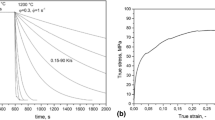

Hu, Z.Q., Wang, K.K., Yang, Y.: Deformation behavior and evolution of Austenite microstructure and texture during Hot Compression of 5CrNiMoV Steel. Metallography Microstruct. Anal. 9(4), 576–587 (2020). https://doi.orghttps://doi.org/10.1007/s13632-020-00662-1

Xu, H., Tian, T., Zhang, J., Niu, L., Zhu, H., Wang, X., Zhang, Q.: Hot deformation behavior of the 25CrMo4 Steel using a Modified Arrhenius Model. Materials. 15(8), 2820 (2022). https://doi.org

Bao, J.H.: The EBSD Investigation on Microstructure Evolution in Fe-32%Ni Alloy during Multi-Axial forging. Appl. Mech. Mater. 260, 26–28 (2010). https://doi.org/10.1016/j.intermet.2014.12.003

Fleck, N.A., Muller, G.M., Ashby, M.F., Hutchinson, J.W.: Strain gradient plasticity: theory and experiment. Acta Mater. 42(2), 475–487 (1994). https://doi.org

Nix, W.D., Gao, H.: Indentation size effects in crystalline materials: a law for strain gradient plasticity. J. Mech. Phys. Solids. 46(3), 411–425 (1998). https://doi.org

Gao, H., Huang, Y., Nix, W.D., Hutchinson, J.W., Theory: J. Mech. Phys. Solids. 47(6), 1239–1263 (1999). https://doi.org

Kubin, L.P., Mortensen, A.: Geometrically necessary dislocations and strain-gradient plasticity: a few critical issues. Scr. Mater. 48(2), 119–125 (2003). https://doi.org/10.1016/S1359-6462(02)00335-4

Hughes, D.A., Hansen, N., Bammann, D.J.: Geometrically necessary boundaries, incidental dislocation boundaries and geometrically necessary dislocations. Scr. Mater. 48(2), 147–153 (2003). https://doi.org

Calcagnotto, M., Ponge, D., Demir, E., Raabe, D.: Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A-Struct Mater. Prop. Microstruct. Process. 527(10), 2738–2746 (2010). https://doi.org

Jiang, J., Britton, T.B., Wilkinson, A.J.: Evolution of dislocation density distributions in copper during tensile deformation. Acta Mater. 61(19), 7227–7239 (2013). https://doi.org/10.1016/j.actamat.2013.08.027

Liu, H.H., Fu, P.X., Liu, H.W., Sun, C., Du, N.Y., Li, D.Z.: Effect of vanadium micro-alloying on the microstructure evolution and mechanical properties of 718H pre-hardened mold steel. J. Mater. Sci. Technol. 35(11), 2526–2536 (2019). https://doi.org/10.1016/j.jmst.2019.04.033

Liu, H.H., Fu, P.X., Liu, H.W., Sun, C., Sun, M.Y., Li, D.Z.: A novel large cross-section quenching and tempering mold steel matching excellent strength–hardness–toughness properties. Mater. Sci. Eng. A-Struct Mater. Prop. Microstruct. Process. 737, 274–285 (2018). https://doi.org/10.1016/j.msea.2018.09.046

Acknowledgements

The authors would like to sincerely thank the National Key Research and Development Program of China (2017YFB0701803)for its financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yong-qiang, W., Yong-shan, W. & Kai-kun, W. EBSD analysis of microstructure between liquid core forging process and traditional forging process. Int J Interact Des Manuf 17, 1653–1664 (2023). https://doi.org/10.1007/s12008-023-01224-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-023-01224-9