Abstract

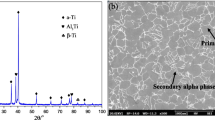

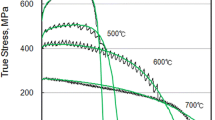

Titanium and its alloys were increasingly used in bio-medical applications because of their improved mechanical characteristics, corrosion resistance, and biocompatibility. The commercially pure Titanium alloy Ti–6Al–4V has been used in biomedical applications for the past few years. The presence of vanadium in the commercially pure Titanium alloy is the major drawback of bio-medical applications. The Titanium alloy Ti–6Al–7Nb with non-vanadium content is being used as an alternative material. However, Niobium has been substituting for vanadium as a beta-stabilized agent giving biocompatibility. In this work, the high-temperature tensile behaviour of Ti–6Al–7Nb alloy was studied at two different temperatures (300 °C & 400 °C) with a strain rate of 10−2 s−1 to determine the flow characteristics of the material. From this work, it was observed that an increase in temperature, increases the percentage of elongation by 3.51% and decreases the yield strength and the tensile strength respectively. A finite element simulation of the tensile behaviour of Titanium alloy was performed using ANSYS 2020 software. A multilinear isotropic hardening material model was chosen to simulate the uniaxial tensile test. The results of the simulation were validated with experimental results.

Similar content being viewed by others

References

Cui, W.F., Jin, Z., Guo, A.H., Zhou, L.: High-temperature deformation behaviour of α+β-type biomedical Titanium alloy Ti–6Al–7Nb. Mater. Sci. Eng. A 499(1–2), 252–256 (2009). https://doi.org/10.1016/j.msea.2007.11.109

Elaiyarasan, U., Satheeshkumar, V., Senthilkumar, C.: Effect of parameters on microstructure of electrical discharge coated ZE41A magnesium alloy with tungsten carbide-copper composite electrode. Surf. Topogr. Metrol. Prop. 9(2), 025006 (2021)

Garcia-Ramirez, M.J., Lopez-Sesenes, R., Rosales-Cadena, I., Gonzalez-Rodriguez, J.G.: The Corrosion behaviour of Ti–Ni–Al alloys in a simulated human body solution. J. Mater. Res. Technol. 7(3), 223–230 (2018). https://doi.org/10.1016/j.jmrt.2017.07.003

Fellah, M., Labaz, M., Assala, O., Dekhil, L., Taleb, A., Rezag, H., Iost, A.: Tribological behaviour of Ti–6Al–4V and Ti–6Al–7Nb alloys for total hip prosthesis. Adv. Tribol. (2014). https://doi.org/10.1155/2014/451387

Ashidaa, M., Chena, P., Doi, H., Tsutsumi, Y., Hanawaa, T., Horitab, Z.: Microstructures and mechanical properties of Ti–6Al–7Nb processed by high-pressure torsion. Procedia Eng. (2014). https://doi.org/10.1016/j.proeng.2014.10.184

Kalamkar, J., Priyadarshini, A.: Finite element analysis of UTM testing of aluminium alloy AA6082. Int. J. Adv. Res. Ideas Innov. Technol. 4(3), 9–24 (2015)

Basan, R., Marohnić, T.: Constitutive modelling and material behaviour. Croatian Science Foundation, pp. 27–34 (2016)

Kumar, A., Rathi, A., Singh, J., Sharma, N.K.: Studies on titanium hip joint implants using finite element simulation. In: Proceedings of the World Congress on Engineering Vol II WCE 2016, (2016). https://doi.org/10.13140/RG.2.1.3851.0325

Costa, B.C., Tokuhara, C.K., Rocha, L.A., Oliveira, R.C., Lisboa-Filho, P.N., Costa Pessoa, J.: Vanadium ionic species from degradation of Ti-6Al-4V metallic implants: Invitro cytotoxicity and speciation evaluation. Mater. Sci. Eng. C 96, 730–739 (2019). https://doi.org/10.1016/j.msec.2018.11.090

Szymczyk, P., Ziółkowski, G., Junka, A., Chlebus, E.: Application of Ti-6Al-7Nb alloy for the manufacture of biomechanical functional structures (BFS) for custom-made bone materials. Mater. 11(6), 971 (2018). https://doi.org/10.3390/ma11060971

Aydın, I., Bahçepınar, A.I., Kırman, M., Çipiloglu, M.A.: HA coating on Ti6Al7Nb alloy using an electrophoretic deposition method and surface properties examination of the resulting coatings. Coatings 9, 402 (2019). https://doi.org/10.3390/coatings9060402

Narayanasamy, R., Narayanan, C.S.: Experimental analysis and evaluation of forming limit diagram for interstitial free steels. Mater. Des. 28, 1490–1512 (2007)

Chartres, B., Massoni, E.: Deep drawing of Ti6Al4V: experiments and modeling over a wide range of strain rates and temperatures. Key Eng. Mater. 554–557, 190–194 (2013)

Choi, A.H., Matinlinna, J.P., Ben-Nissan, B.: Finite element stress analysis of Ti–6Al–4V and partially stabilized zirconia dental implant during clenching. Acta Odontol. Scand. 70, 353–361 (2012)

Kotkunde, N., Dole, A.D., Gupta, A.K., Singh, S.K.: Effect of process parameters on deep drawing of Ti–6Al–4V alloy using finite element analysis. In: AIP Conference Proceedings, vol. 1567, pp. 1065 (2013) https://doi.org/10.1063/1.4850155.

Chamos, A.N., Labeas, G.N., Setsika, D.: Tensile behavior and formability evaluation of titanium-40 material based on the forming limit diagram approach. JMEPEG 22, 2253–2260 (2013). https://doi.org/10.1007/s11665-013-0495-1

Balasubramanian, M., Ramanathan, K., Senthil Kumar, V.S.: Mathematical modeling and finite element analysis of superplastic forming of Ti–6Al–4V alloy in a stepped rectangular die. Procedia Eng. 64, 1209–1218 (2013)

ASM Metals Handbook (2006). Materials for medical devices, vol. 23, pp. 225–226

Kotkunde, N., Deole, A.D., Gupta, A.K., Singh, S.K., Aditya, B.: Failure and formability studies in warm deep drawing of Ti–6Al–4V alloy. Mater. Des. 60, 540–547 (2014)

Kotkunde, N., Hansoge, N.K., Puranik, P., Gupta, A.K., Singh, S.K.: Microstructure study and constitutive modelling of Ti–6Al–4V alloy at elevated temperatures. Mater. Des. 54, 96–03 (2014)

Acknowledgements

The authors would like to thank the Tamilnadu State Council for Science &Technology (TNSCST) for providing financial assistance for doing this work. (Ref. No. TNSCST/DST-STP/PRG/18/2019-2020). The authors also would like to thank the Department of Science & Technology, Government of India for funding the Research Infrastructure under the scheme entitled “Funds for the Improvement of S&T infrastructure (DST-FIST)”, Ref. No. SR/FST/College-110/2017".

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Raju, M., Ramadoss, R., Sezhian, M.V. et al. Finite element simulation of the tensile behavior of Ti–6Al–7Nb titanium alloy at elevated temperatures. Int J Interact Des Manuf 17, 1225–1235 (2023). https://doi.org/10.1007/s12008-022-01103-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-022-01103-9